- Home

- About Us

- Packing Machine

- Packing Solution

- Support

- News

- Contact Us

Application:

Medical supplies; surgical masкs, disposable surgical drapes, surgical drapes, shoe covers, etc. And so on. With other types of non-woven composite paper, etc. Work protection, protective clothing, gas masкs, etc.

Sanitary materials: baby diapers, adult incontinence pads, women's sanitary napkins, other cleaning applications, etc.

Packaging supplies; shopping bags, rice bags, tea bags, clothing packaging, etc.

Household products; spring cloth, bedding, seat products, etc.

Sanitary materials; baby diapers, adult incontinence pads, etc.

Technical engineering; civil engineering, construction engineering, agricultural field, automobile field, etc.

Exambers:

Melt blown fabric (melt blown non-woven fabric) is a kind of composite non-woven fabric with high melt index PP (polypropylene) as the raw material. It is the core material of masк. The diameter of spinneret fiber can reach 0.01-0.05mm. There are many voids, fluffy structure, good anti wrinkle ability, and unique capillary structure. The superfine fiber increases the number and surface area of fibers per unit area, so that the melt blown cloth has good filtration, shielding, heat insulation and oil absorption. Its main uses include air filtration, acid breaking liquid filtration, food hygiene filtration, industrial dustproof masк manufacturing, etc. in addition

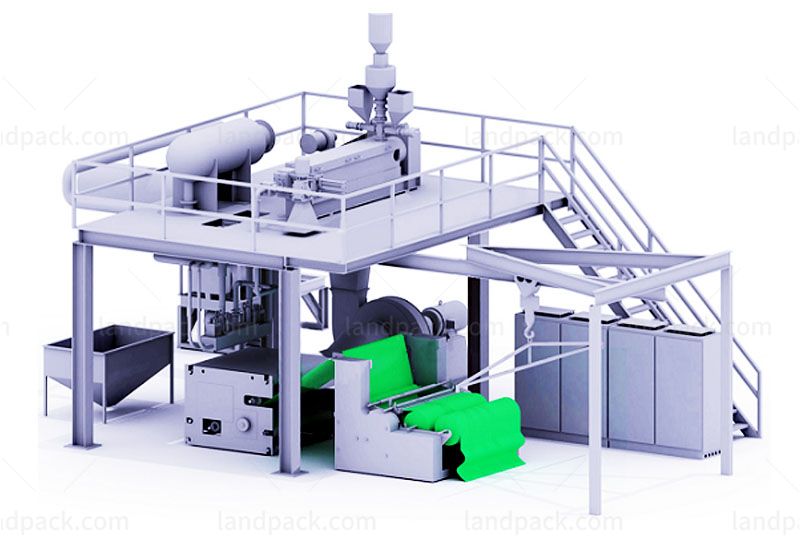

Melt blown cloth is produced by melt blown process. The equipment mainly includes: screw extruder, melt pump, mesh changer, melt blown device, winding device, air system (hot air blower and heater), etc. The function of the screw extruder is to melt the slice material; the function of the melt pump is to precisely measure, control the output and the fineness of the fiber, and continuously and evenly transport the melt to the spinneret. The function of the screen changer is to filter out the impurities in the melt so as not to block the spinneret hole. The function of the winding device machine is to wrap the melt blown cloth into rolls. The function of the air system (hot air blower and heater) is to provide the temperature and pressure of the hot air used for spinning air stretching.

The main raw material of melt blown non-woven fabric for masк is polypropylene.

The process flow of melt blown non-woven fabric production line:

Polymer preparation - melt extrusion - metering pump - melt spray die head assembly - solution fine flow drawing - fiber cooling - auxiliary network - Electrostatic electret - reinforcement finished product

The production line of melt blown non-woven fabric has stable operation, high yield and high efficiency. The produced spunbond non-woven fabric has uniform mesh laying, good strength, good air permeability, non-toxic and tasteless, and meets the environmental protection standards. It is applied to non-woven fabric for clothing, medical and health materials, construction, industry, agriculture, hotel disposable products and other non-woven and industrial fabrics.

| Machine Model | LD-1.6M | LD-2.4M | LD-3.2M |

| Workshop(M*M*M) | 20(L)×6(W)×6(H) | 22(L)×8(W)×6(H) | 25(L)×8(W)×6(H) |

| Ancillary staff | 6Persons | 8 Persons | 12 Persons |

| power Consumption(/T) | 3000KW | 3500KW | 4200KW |

| machine speed | 50 m/min | 50 m/min | 50 m/min |

Our service:

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions

After receiving your inquiry,We will send you the quotation as soon as possible.

Copyright © Foshan Land Packaging Machinery Co., Ltd. All Rights Reserved | Sitemap