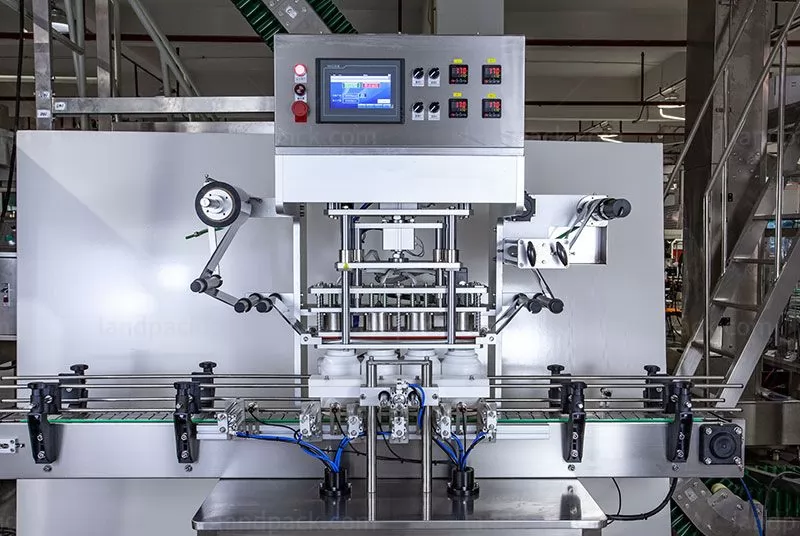

1. This machine applies optical, electric, and air integration design, and features a compact structure, beautiful appearance and sealing, high efficiency, simple operation, and easy maintenance.

2. The heat sealing head and bottle clip device have been specially made according to the customer's bottle size fully automatic solution, to realize feeding, weighing, filling, servo capping, foil sealing, and labeling.

3. The machine can be controlled through the touch screen, about 30 bottles/minute.

Workflow:

1. This machine mainly consists of a frame, film-sending device, film recycle device, heat sealing head, bottle-sending and stacking device, and electric and pneumatic control box.

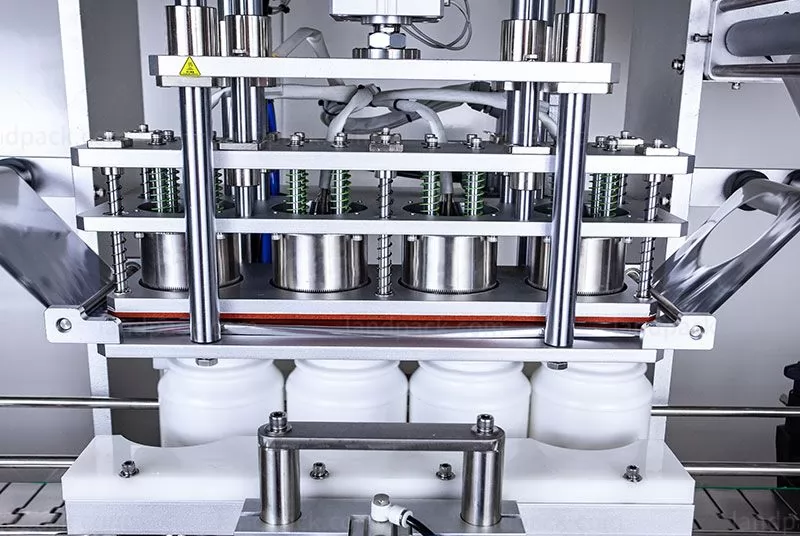

2. Working as a heat sealing principle, the film is set by the film film-sending device to the guide wheel, then the positioning wheel, and then to the film recycle device.

3. The heat sealing head and bottle clip device have been specially made according to the customer's bottle size full automatic solution.

4. The entire procedure is driven by a gear motor and pulley, sending the film and recycling film automatically by electric and pneumatic control.

5. The bottle will be transferred by the conveyor when the bottle is transferred to the special position where there will be a photoelectric sensitive switch to test the signal. When there is a signal, the bottle sticking air cylinder will pull out to stop the bottle, then seal automatically.

6. After sealing is finished, the bottle-sticking air cylinder will be pulled in to proceed to the next sealing procedure.