Application:

Sandwich biscuits packaging lines are perfect for use in large-scale bakery factories, biscuit factories as well as food processing factories. It can effectively manage a variety of sandwich-based products, including chocolate-coated biscuits, cream-filled cookies, jam-filled pastries and wafers with multiple layers.

Suitable Industry:

This machine has been designed for sandwiches, biscuits and filled pastry with seamless functions for feeding and arranging, sandwiching, stacking and packaging. It is used extensively in the bakery and confectionery industries, allowing a wide assortment of shapes, tastes and fillings ranging from chocolate, cream and jam to a variety of nutritious ingredients.Here are some common uses and the types of products that are available:

* Sandwich Biscuits::

Classic cream-filled biscuits, Chocolate-coated sandwich biscuits, Double-layer sandwich cookies, Round and square sandwich biscuits

* Wafers & Crackers:

Wafer Sheets: Layered cream wafers, chocolate wafers

Savory Crackers: Salted crackers, cheese crackers, vegetable crackers

* Cookies & Pastries with Filling:

Butter cookies with cream or jam, Chocolate chip sandwich cookies, Fruit-filled soft pastries, Innovative flavor cookies

* Wafers & Layered Snacks:

Cream-filled wafers, Chocolate-coated wafers, Multi-layer wafer sandwiches

* Healthy & Customized Snacks:

Protein sandwich biscuits, Sugar-free sandwich cookies, Whole grain filled crackers, Tailored flavor sandwich snacks

Packaging Style:

This high-speed biscuit sandwiching machine is suitable for packing back sealing bags, pillow bags with or without easy tear.

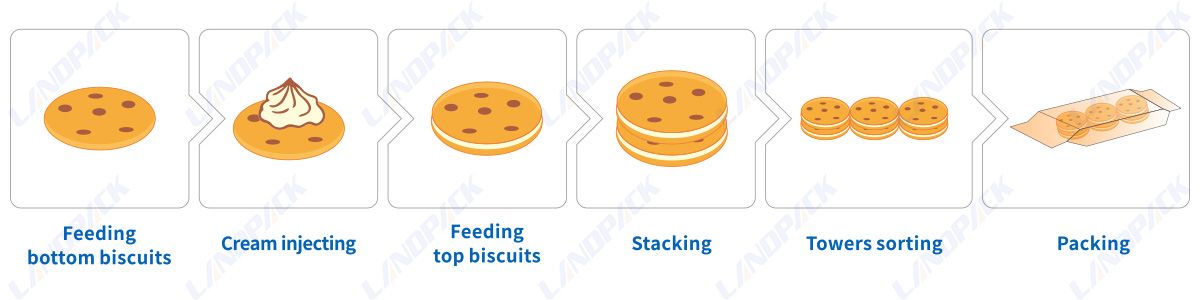

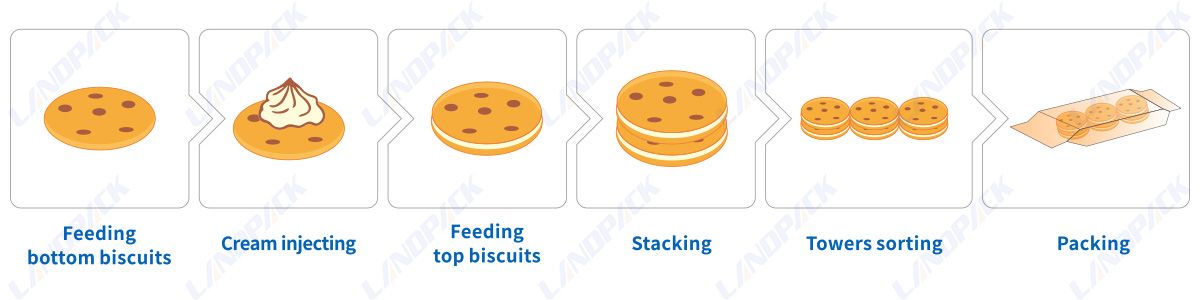

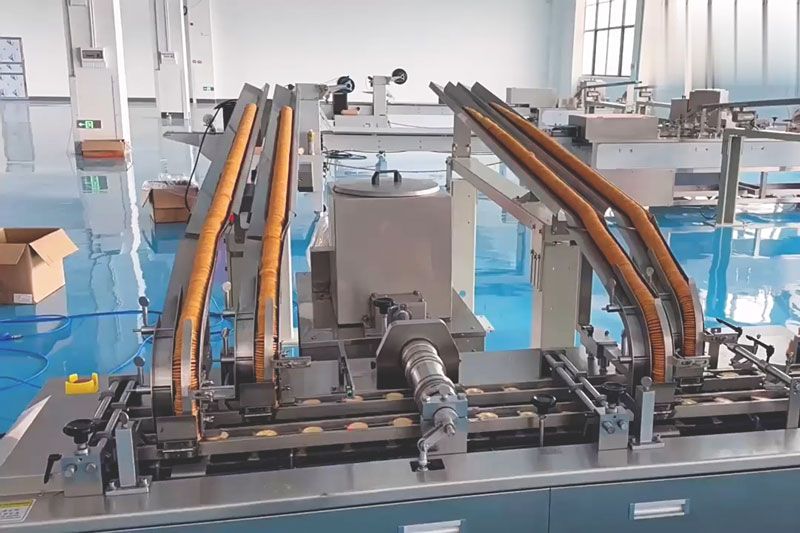

Biscuit Sandwich Production Process:

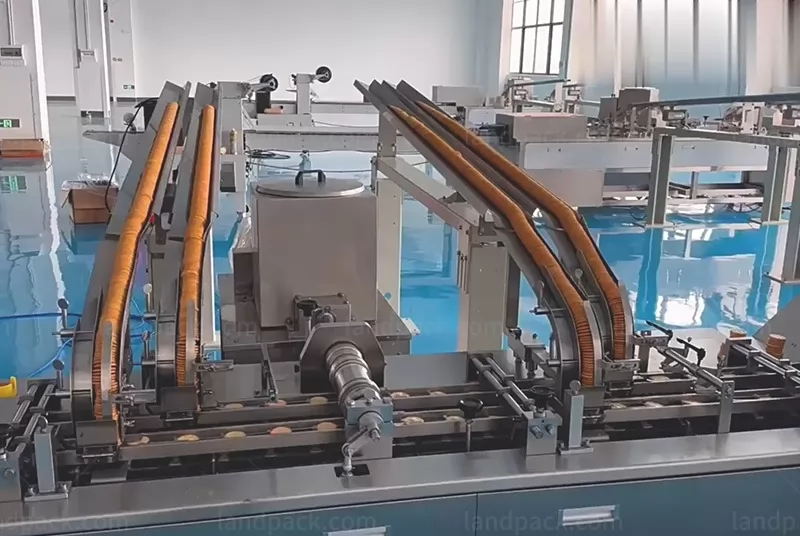

* Feeding & Conveying

– Biscuits are gently pushed onto the conveyor, and then arranged through neat lines. The system is designed to ensure an uninterrupted flow of the biscuits without causing any damage to fragile items.

* Cream Filling – A precise dosing system that applies chocolate, cream or jam on the biscuits' bottom. This ensures an accurate density, weight uniformity and a consistent quality.

* Biscuit Alignment & Sandwiching – These top cookies are then synchronized and placed on top of the bottoms. This creates perfect sandwiches with minimal loss of product and keeping clean shapes.

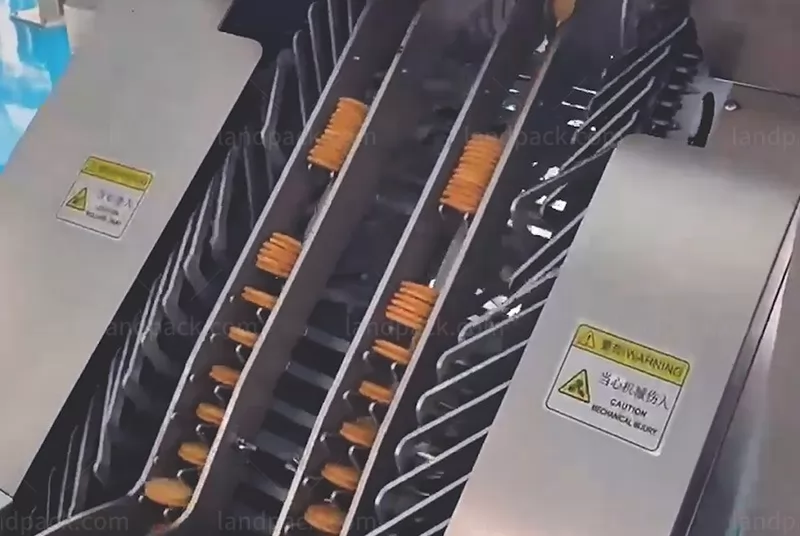

* Counting & Grouping – The sandwiches that are finished are automatically counting and then they are grouped.

* Film Feeding & Bag Forming – The flow wrapping machine is fed with roll film, which is then shaped into pouches. Each biscuit is sealed to protect freshness and prolong shelf life.

* Discharge & Output – Completed packages are delivered by the conveyor at the output. They may be picked up directly or redirected to cartoning equipment to be used for packaging.