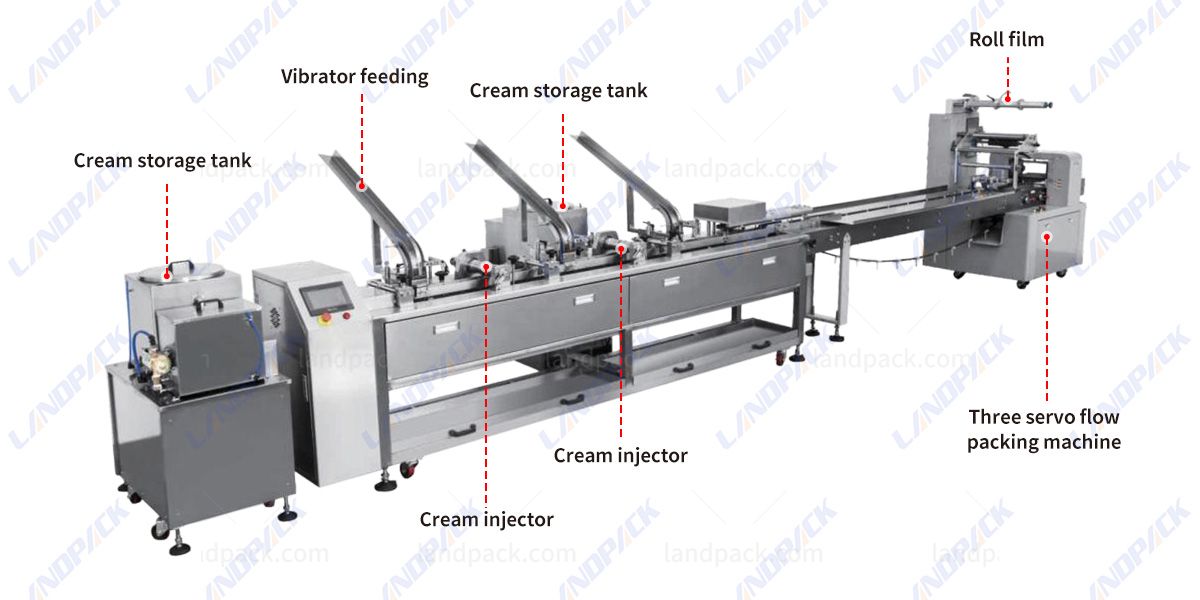

Application:

The sandwich biscuit pillow packaging machine is specifically designed for packaging biscuits with cream filling, cookies. Ideal for packaging products like chocolate biscuits, wafer cookies, cream-filled crackers, and other similar snacks.

* Baked Goods & Snacks: sandwich biscuits & cookies, chocolates & confectioneries, chips, crackers & breadsticks

* Frozen & Perishable Foods: frozen meat products, frozen fruits & vegetables, sandwiches, doughnuts

* Non-Food Products: face masks, medicine, capsules, small toys, tools, household products

It provides stability and a streamlined packaging that can accommodate a variety of textures and shapes, which makes it a great choice for large-scale bakery and snack production.

Packaging Style:

This high-speed packing and feeding line is suitable for packing back sealing bags, pillow bags with or without easy tear.

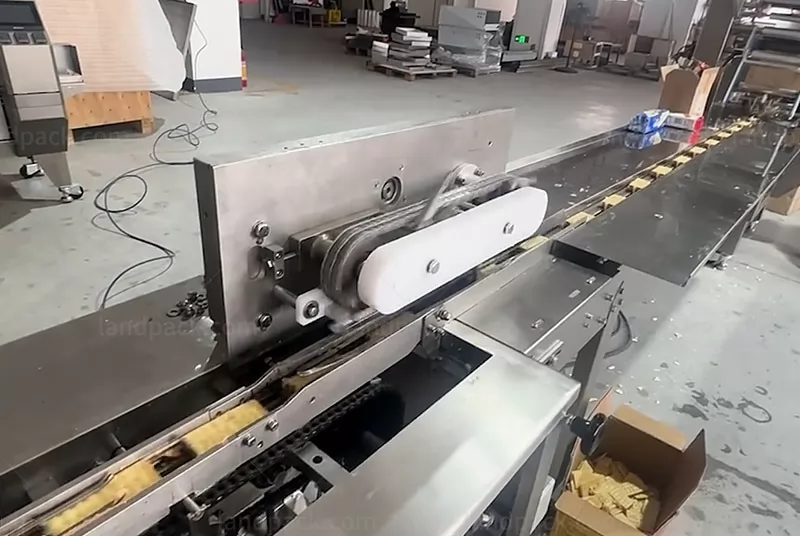

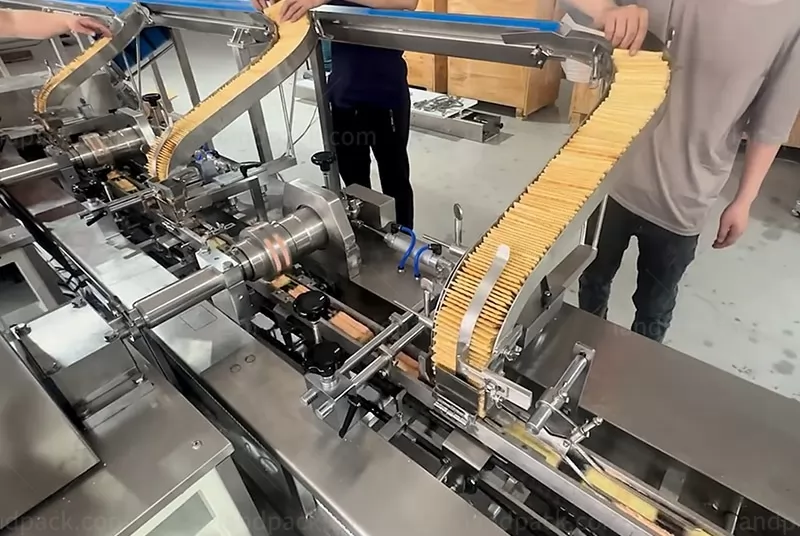

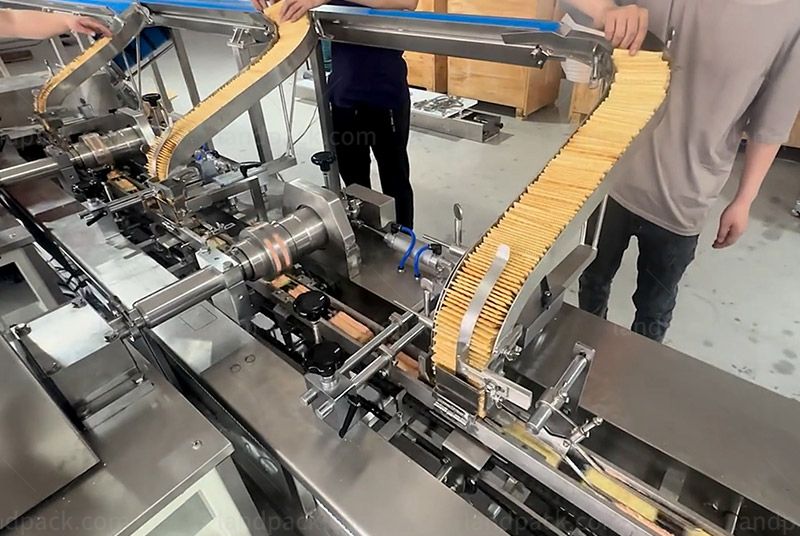

Biscuit Sandwich Production Process:

* Feeding Bottom Biscuits – The bottom layer of biscuits is neatly placed on the production line.

* Cream Injecting – Delicious cream is accurately injected onto each biscuit.

* Middle layer injection – Add the middle layer of cookies to create a perfect sandwich.

* Second layer of cream injection - Complete cream filling.

* Feeding Top Biscuits – The top biscuit is added to form a perfect sandwich.

* Packing – Finished biscuit sandwiches are wrapped and sealed, ready for sale.