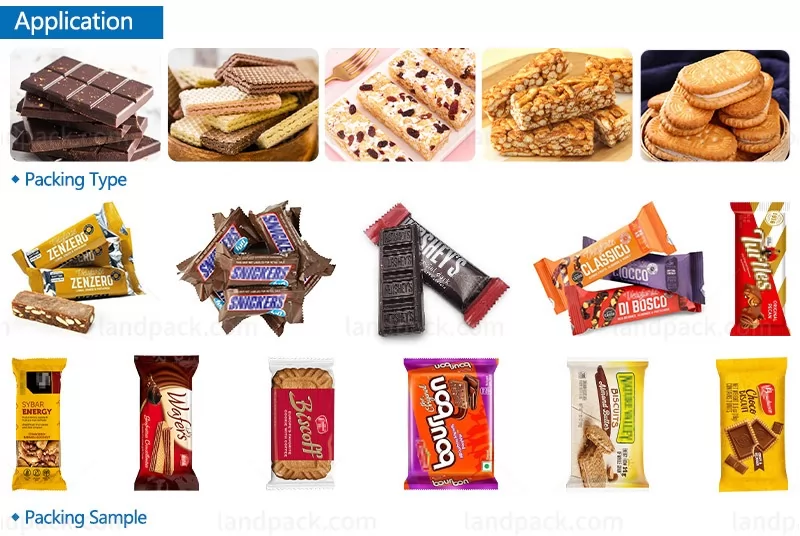

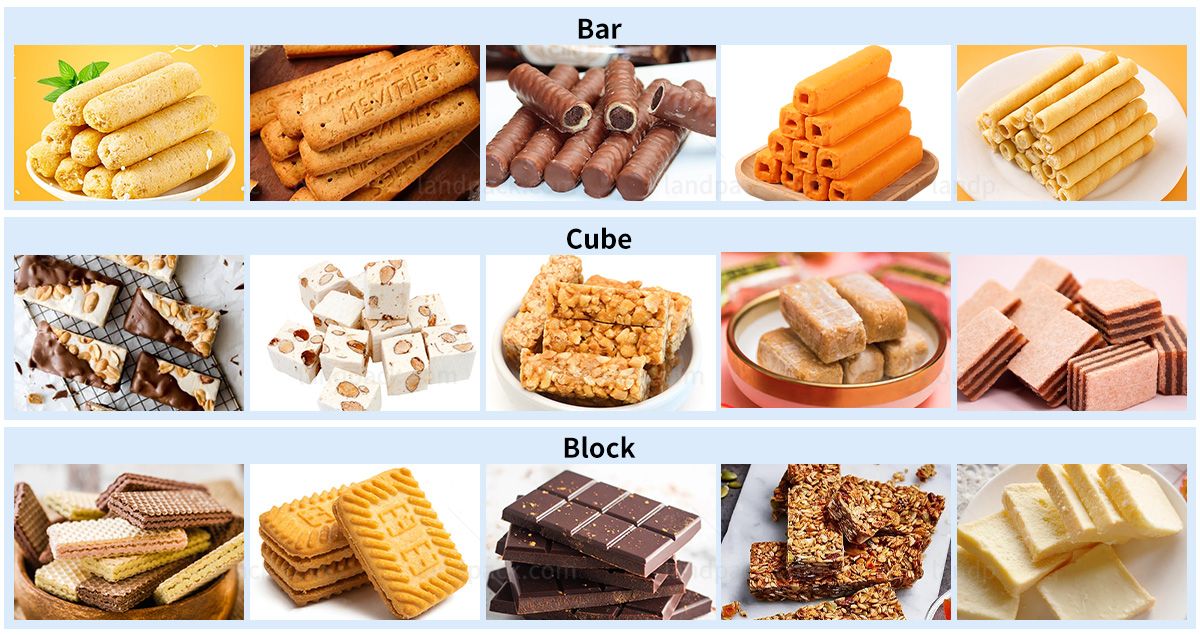

Application:

This flowpack feeding packing machine line is fast, clean, and efficient, handling material in different shapes like bar, cube, and block. It works with back sealing bags and pillow bags, up to 460-690 pcs/min, giving accurate fills and tight seals. Perfect for food, and daily products, it helps increase output, cut waste, and keep products fresh.

Applicable Products:

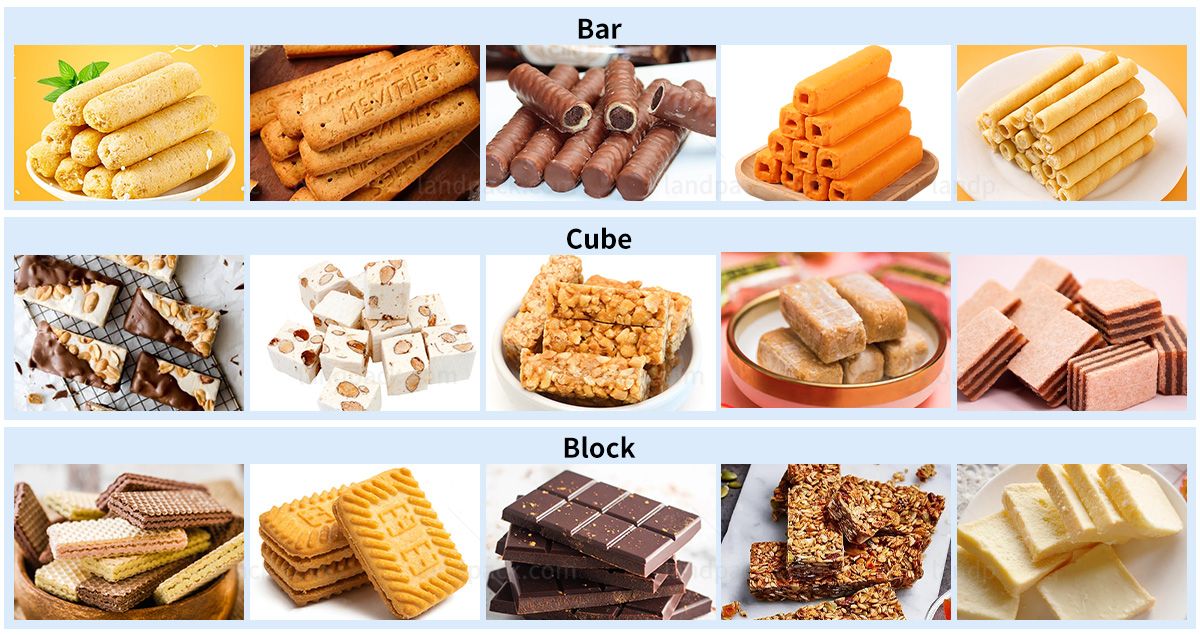

Our machine is designed to handle a wide range of products with different shapes, making it versatile for various industries.

Bar Products – Perfect for packing food items in bar-shaped, such as: Chocolate bars, cereal bars, protein bars, energy bars, granola bars, nougat bars, and fruit bars.

Cube Products – Ideal for small cube-shaped products, including: Chocolate cubes, caramel cubes, fudge cubes, nougat cubes, jelly cubes, cheese cubes, and candy cubes.

Block Products – Suitable for larger block-shaped products, such as: Chocolate blocks, butter blocks, cheese blocks, nougat blocks, marshmallow blocks, and other confectionery blocks.

With this flexibility, the machine provides efficient packaging solutions for the confectionery, dairy, snack, and food processing industries.

Package Type:

This high speed 1+2 feeding packing line is specially designed for chocolate products, supporting two main bag styles:

- Back Sealing Bags: A simple and economical option, widely used for cube chocolates, small bars, and candy pieces.

- Pillow Bags: The most popular style for chocolate bars and blocks, ensuring secure sealing and attractive presentation.

These bag types provide reliable protection and a professional look, making them ideal for chocolate packaging in retail and wholesale markets.

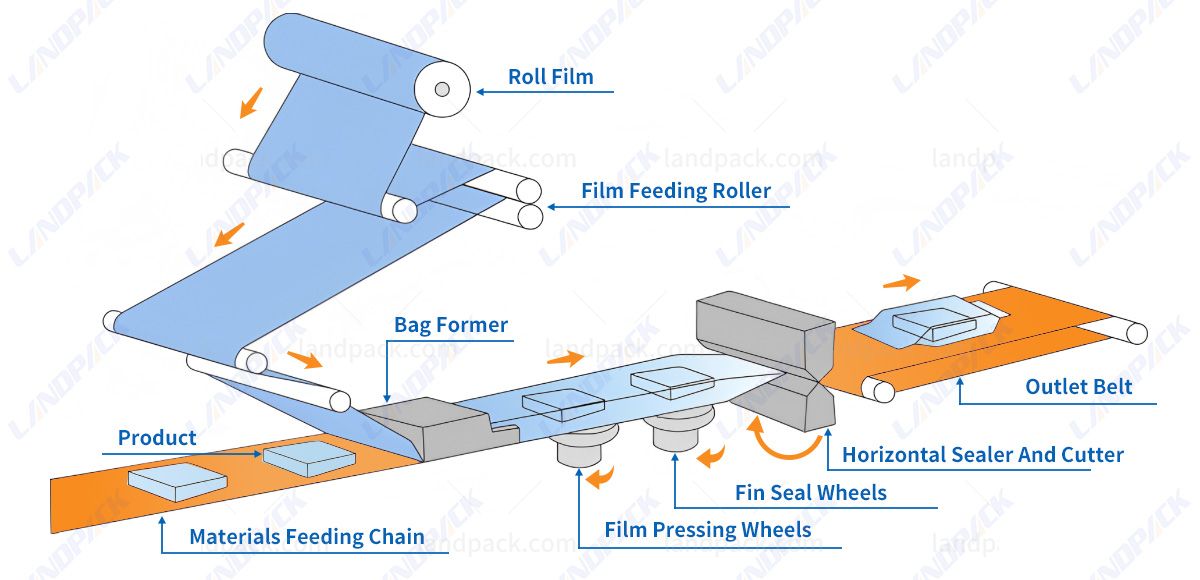

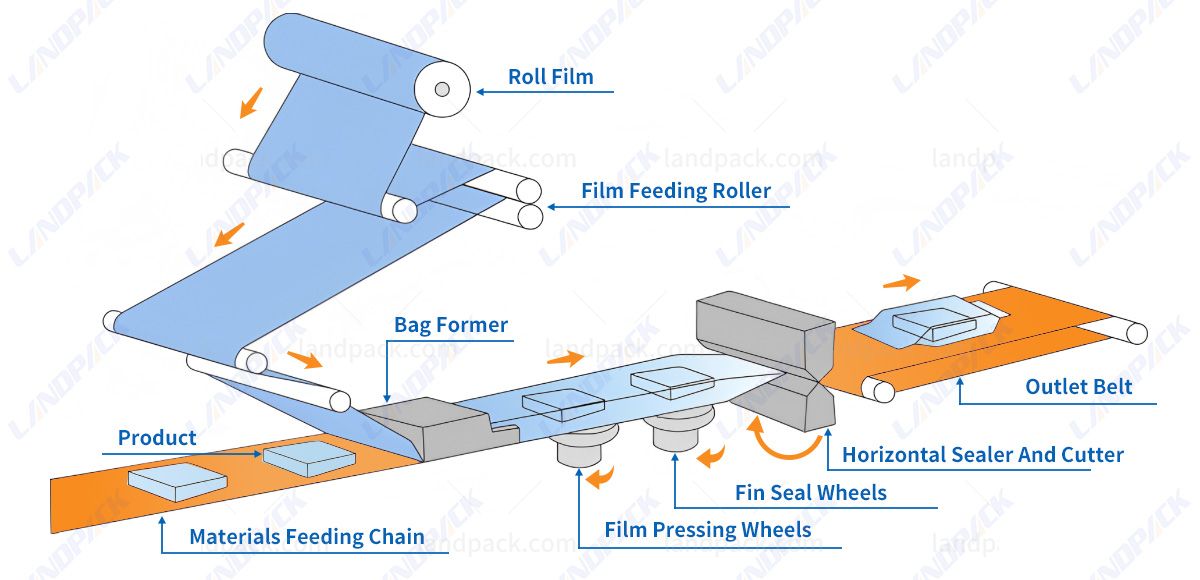

Workflow:

This is a fully automated feeding packing machine line perfect for food and daily products. Here's how it works step-by-step:

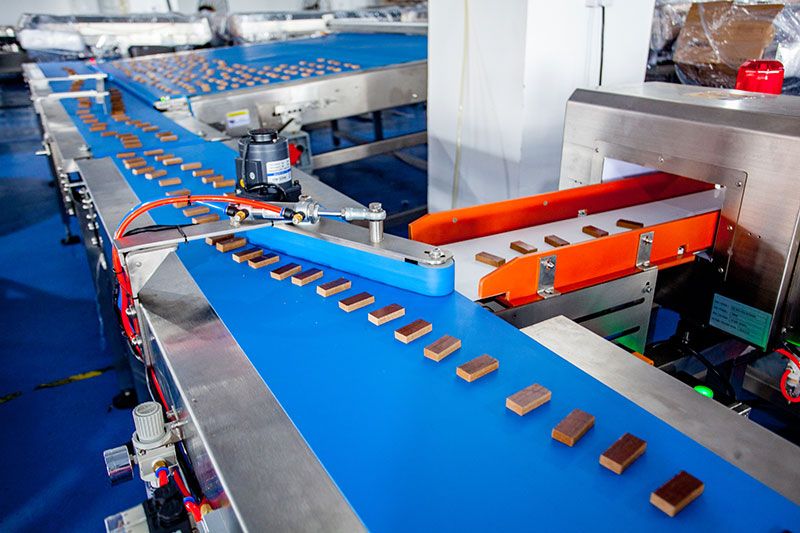

* Automatic Feeding – Products are loaded into the system smoothly and continuously, saving time and labor.

* Intelligent Sorting – The machine organizes products automatically, ensuring accuracy and consistency.

* Streamlined Dividing – Products are evenly separated to keep the flow fast and efficient.

* Metal Detection – Built-in metal detector ensures product safety by identifying and removing any foreign objects.

* Perfect Alignment – Items are neatly arranged, ready for precise packaging.

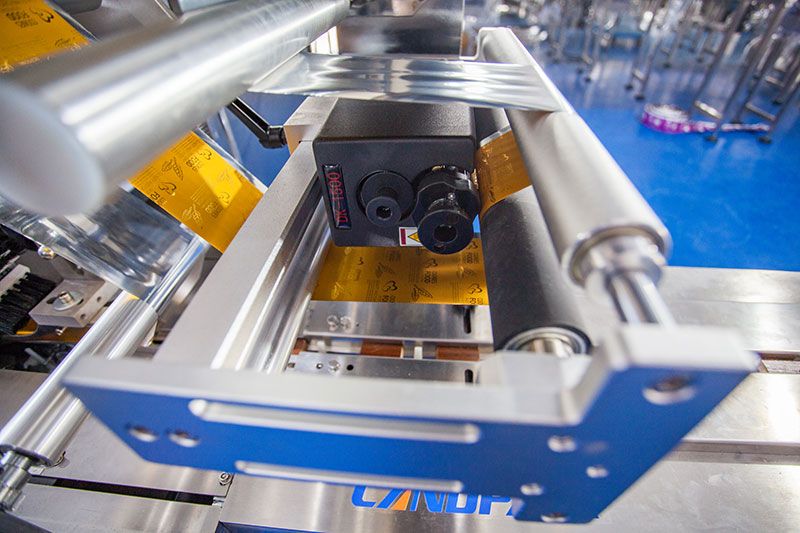

* Bag Forming & Filling – The conveyor carries products into the bag maker, where each bag is formed and filled.

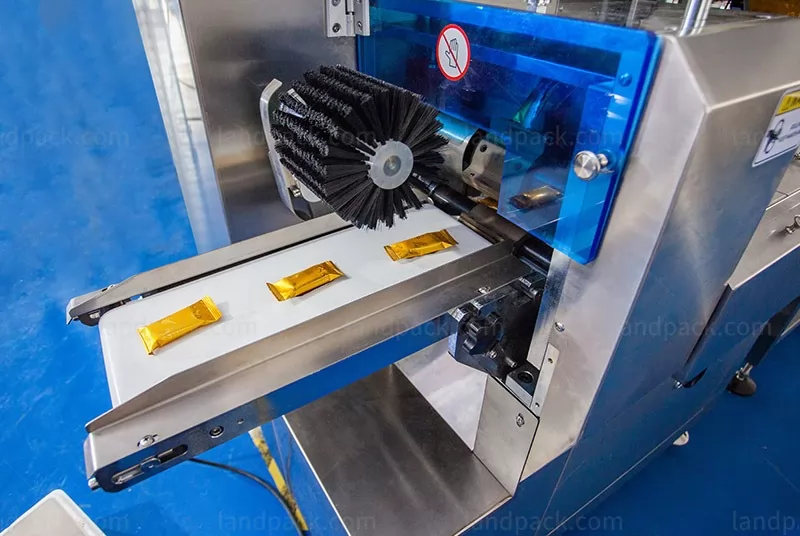

* Secure Sealing – Advanced sealing technology keeps every package airtight and reliable.

* Clean Output – Finished bags are delivered smoothly, ready for secondary packaging or direct distribution.