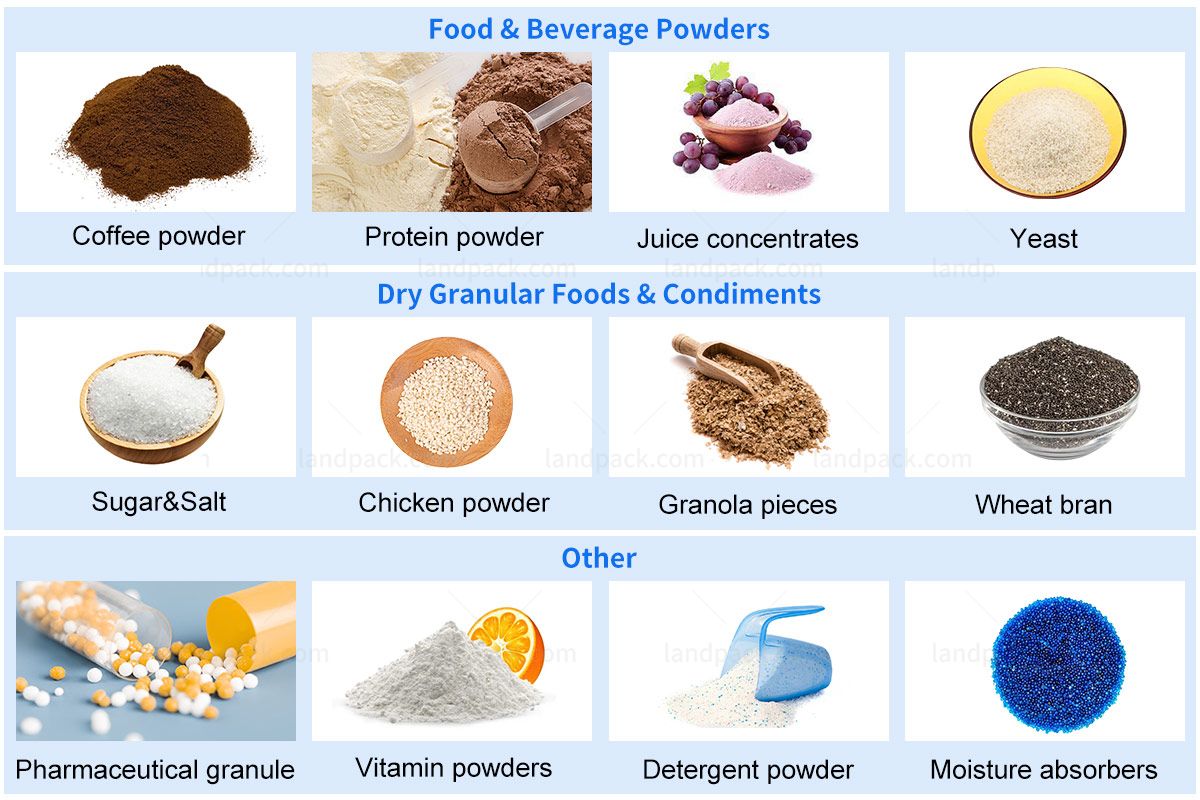

Application:

This multi lane packing machine is widely used for high-speed production of powder stick packs in the food, beverage, and nutrition industries. It is suitable for coffee-based powders such as 3-in-1 coffee, instant coffee, milk tea powder, as well as a broad range of nutritional powders like collagen powder, protein powder, and vitamin powder.

Package Type:

This machine supports lots of packaging types, including stick packs, sachets, and 3 / 4-sides sealing pouches, making it adaptable for a wide range of coffee powders and portioned products. Each pouch style can be customized in size, length, perforation type, easy-tear design, or hanging-hole options.

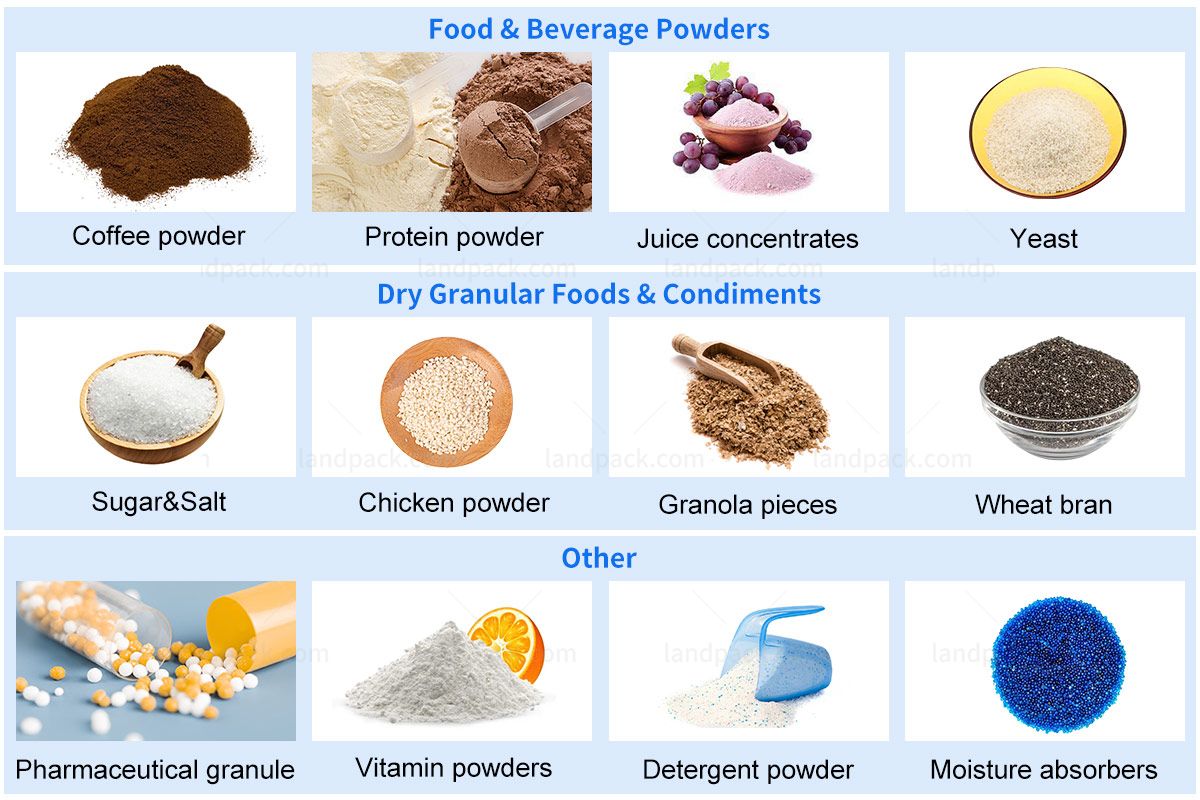

Suitable Products:

The 3 in 1 coffee packing machine is ideal for a wide variety of powde products that require compact stick packs, ensuring high-speed output and precise dosing for both food and beverage industries.

- Coffee & Beverage Powders: 3-in-1 coffee, instant coffee, milk tea powder, cocoa powder.

- Nutritional & Wellness Powders: protein powder sticks, collagen powder, vitamin supplement powders.

- Food Ingredients: sugar, creamer powder, seasoning powder.

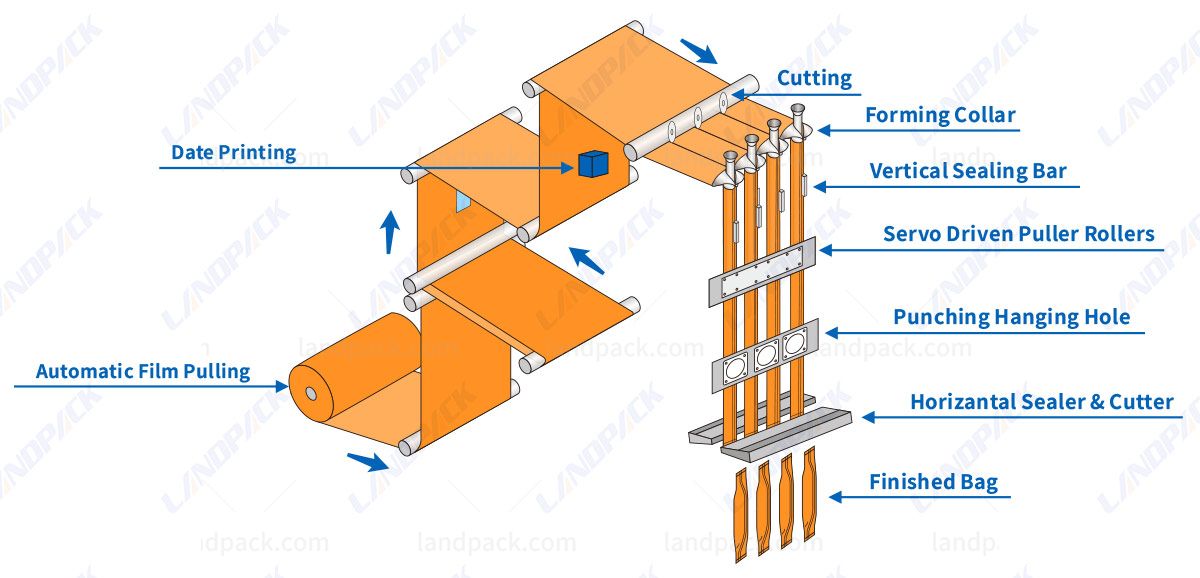

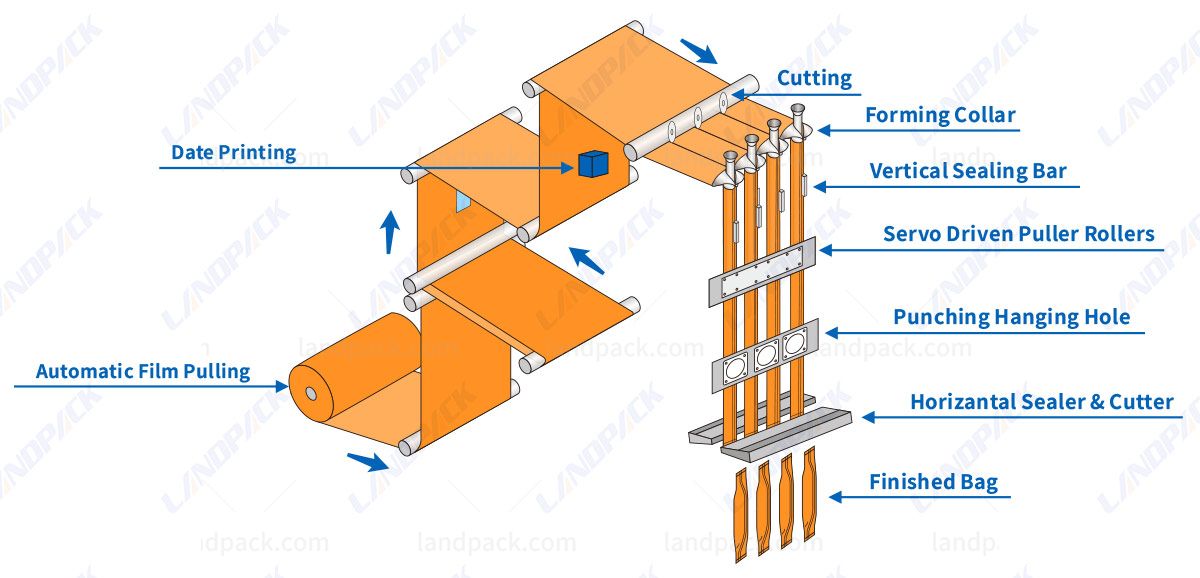

Workflow:

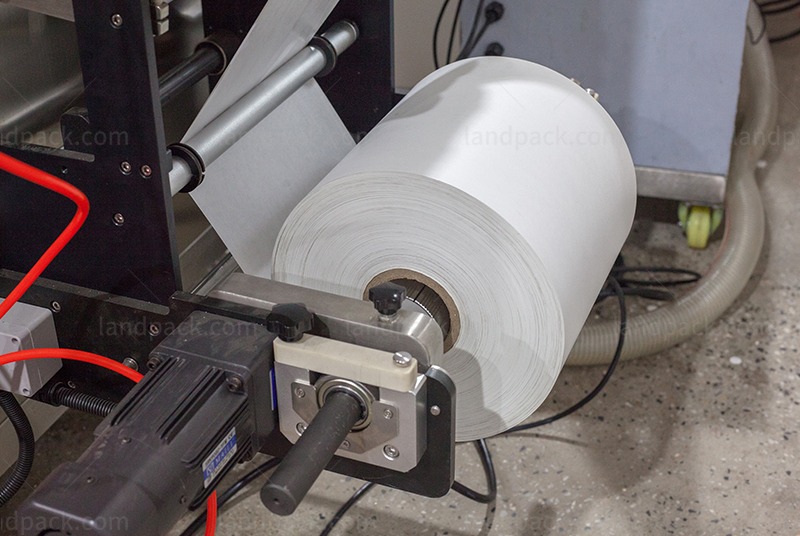

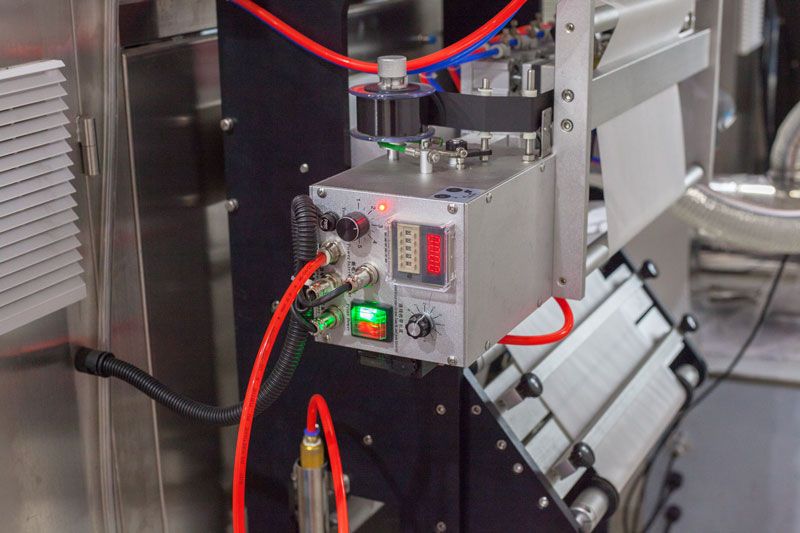

1. Servo driven film pulling - The system servo pulls the film smooth and accurately, providing constant film tension to ensure stick-pack formation.

2. Date Coding - The ribbon creates production dates batches, numbers, or codes on the film.

3. Vacuum Feeding - Powders are transferred automatically into the container for storage.

4. Hanging Hole Punching - A special machine punches holes on the very top of every stick.

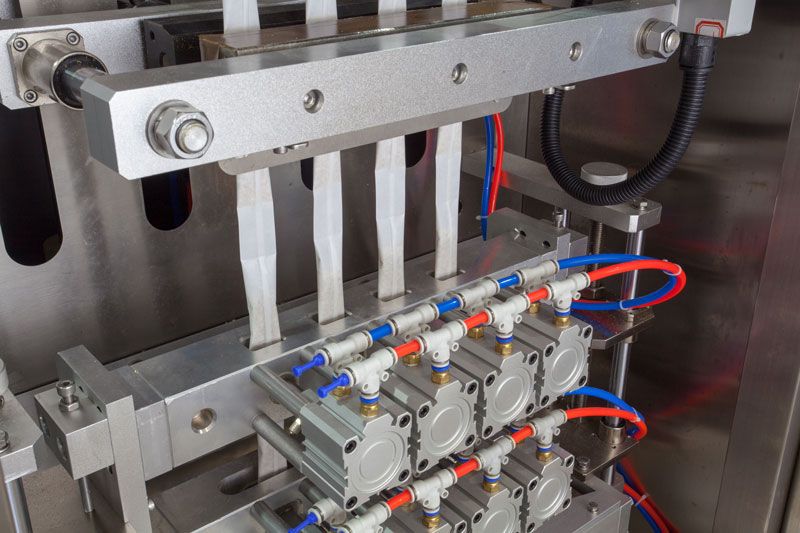

5. Automated Cup Filling - Dosing cups are able to measure and disperse precise quantities of powder into each lane.

6. Stick Bag Forming - Film is shaped around the bag former that form it and closed vertically to form a stick pack at the same time.

7. Cutting and output - The device cut individual pouches and then delivers the finished stick packs neatly to the conveyor.