Features:

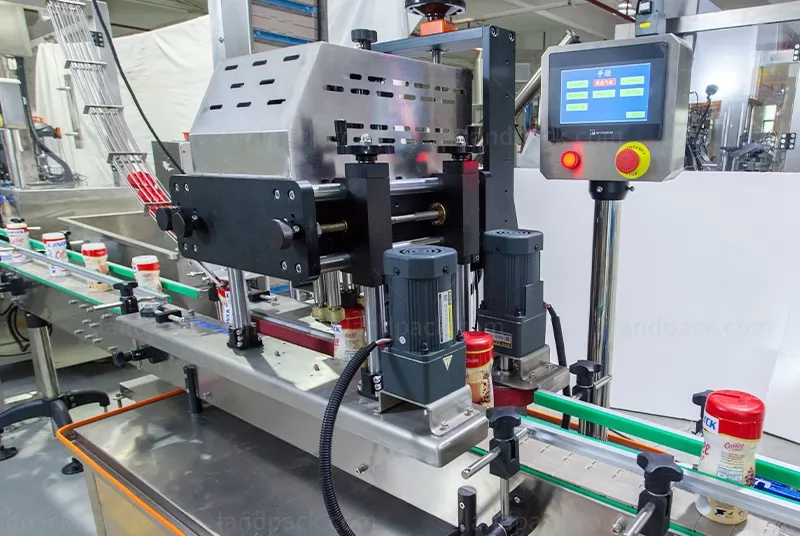

1. Adopts dual auger screw filling system combined with real-time weight checking to achieve high filling accuracy and stable output.

2. Comes with an integrated vacuum feeder for automatic powder supply, with an overall machine height controlled within 3 meters—ideal for limited-space workshops.

3. Filling head is equipped with a vacuum dust removal system to reduce airborne particles, ensuring a clean and safe working environment.

4. User-friendly Siemens/Delta PLC with 7-inch touch screen for intuitive operation, real-time data display, and easy parameter adjustments.

5. Ensures precise bottle placement and alignment before filling to avoid material loss and maintain production consistency.

6. All parts in contact with materials are made from food-grade stainless steel, corrosion-resistant and compliant with GMP standards.

7. Supports filling range customization according to product weight and bottle size, adaptable for different batch production needs.

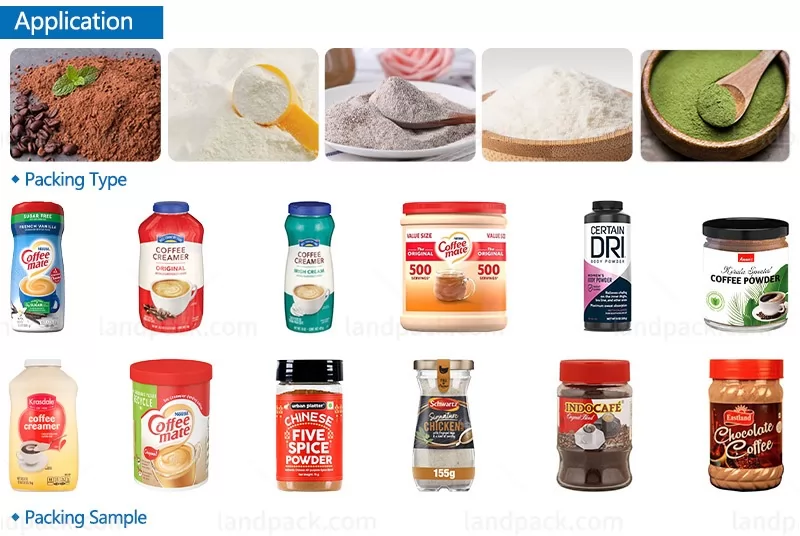

8. Widely applicable for filling premix powders, protein powders, milk powders, and other non-free-flowing or dusty powders.

Composition Structure:

1. Turntable bottle feeder

2. Dual auger screw filling machine with weight check system

3. Cap lifting device

4. Capping machine

5. Aluminum foil sealing machine

6. Collection table