Application:

This fragrance beads filling machine is widely used for air freshener beads, laundry fragrance pearls, aroma beads, fragrance beads, as well as other granular products such as nuts, beans, peanuts, candy, seeds, and potato chips.

Package Type:

The aroma beads filling machine is suitable for plastic bottles (PET/PP/HDPE) and glass bottles, compatible with round, square, and custom-shaped bottles. The line also supports screw cap bottles, press-on caps, and child-resistant caps.

Wide Application Range:

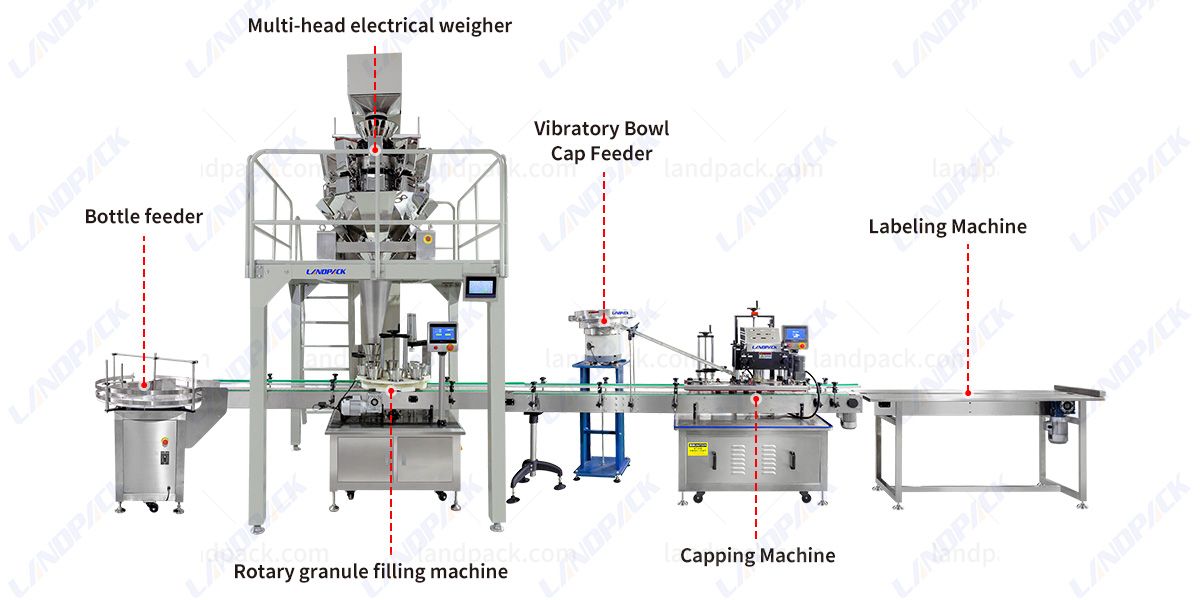

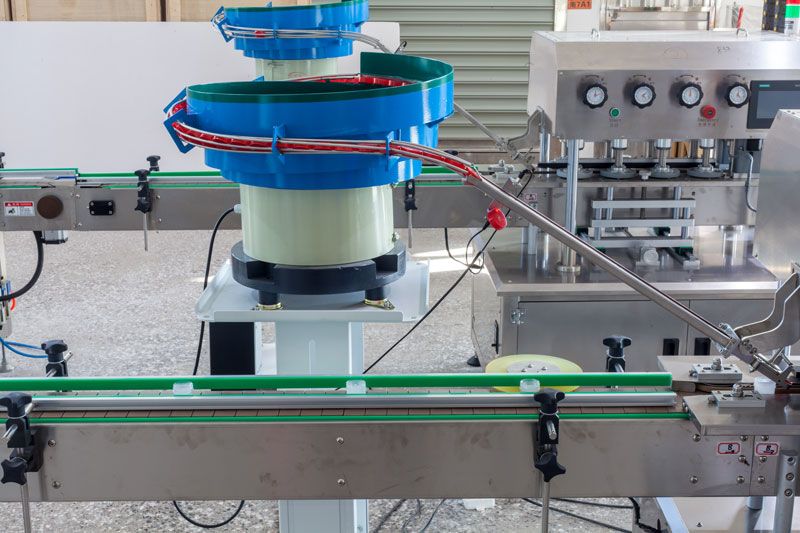

This granule filling line, consisting of a bottle unscrambler, multi-head weigher, granule filling machine, vibration cap feeder, and automatic capping machine, is specially designed for high-efficiency bottling of free-flowing granular products. While optimized for scented beads, it is also widely applicable across multiple industries, including

Home Care Products: Such as laundry scent beads, wardrobe fragrance granules, deodorizing beads, and air-freshener pellets

Food & nutrition items: candy beads, sugar pearls, seasoning granules, and dietary supplements;

Industrial and agricultural products: desiccant beads, fertilizer pellets, and specialty chemical granules.

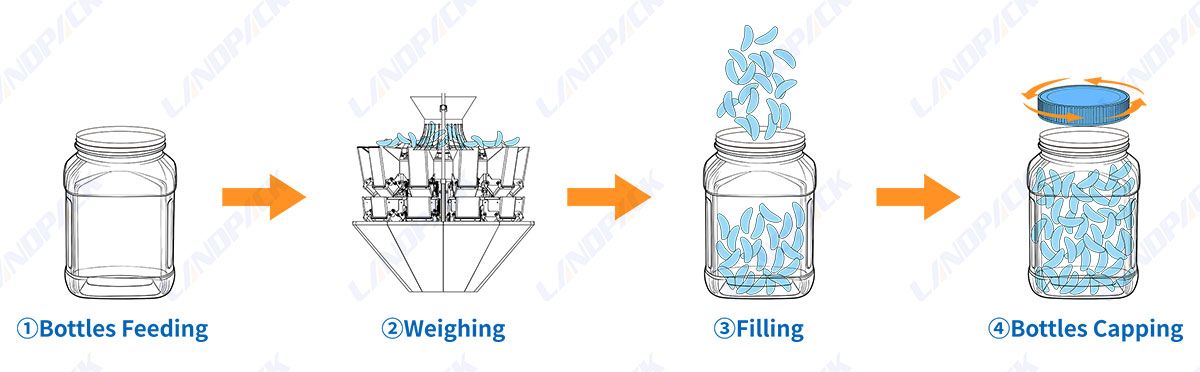

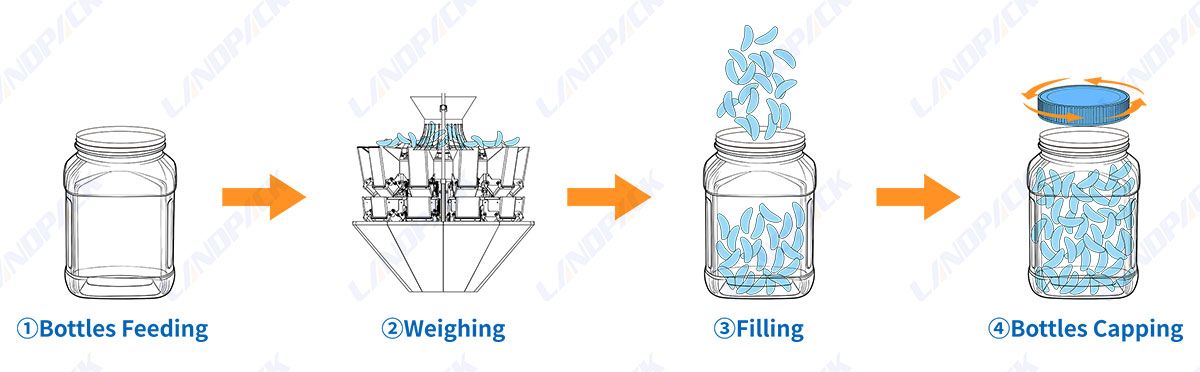

Workflow:

1. Bottle Unscrambling: Empty bottles are automatically aligned and fed by the bottle unscrambler

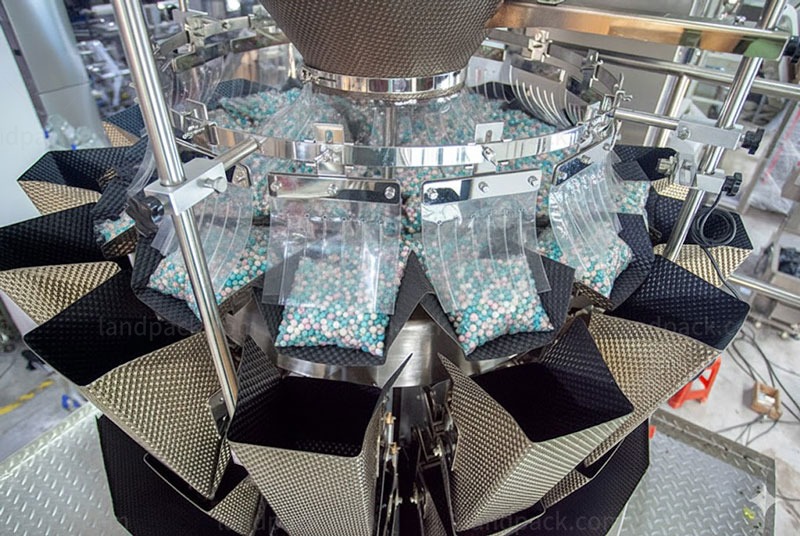

2. Granule Weighing: The multi-head weigher precisely measures the preset weight of fragrance beads or other granular materials

3. Granule Filling: The granule filling machine smoothly discharges the weighed material into bottles, with controlled flow to prevent spillage and product loss.

4. Cap Feeding: Caps are automatically oriented and delivered by the vibrating bowl, ensuring correct direction and steady feeding to match the filling speed.

5. Automatic Capping: The capping machine securely tightens caps onto bottles with uniform torque

6. Finished Product Collection: Filled and capped bottles are conveyed to the collection table, ready for packing, storage, or downstream packaging processes.