Application:

This fragrance beads filling machine is also well-suited for non food or food grade granular products include scented laundry beads, beans, nuts, dry fruits, candy, cereal, chocolate, biscuit.

Package Type:

This filling line is specifically designed for bottles and jars, including round plastic bottles, PET jars, wide-mouth containers, and rigid packaging commonly used for fragrance beads, granular detergents, food granules, and chemical pellets.

Wide Application Range:

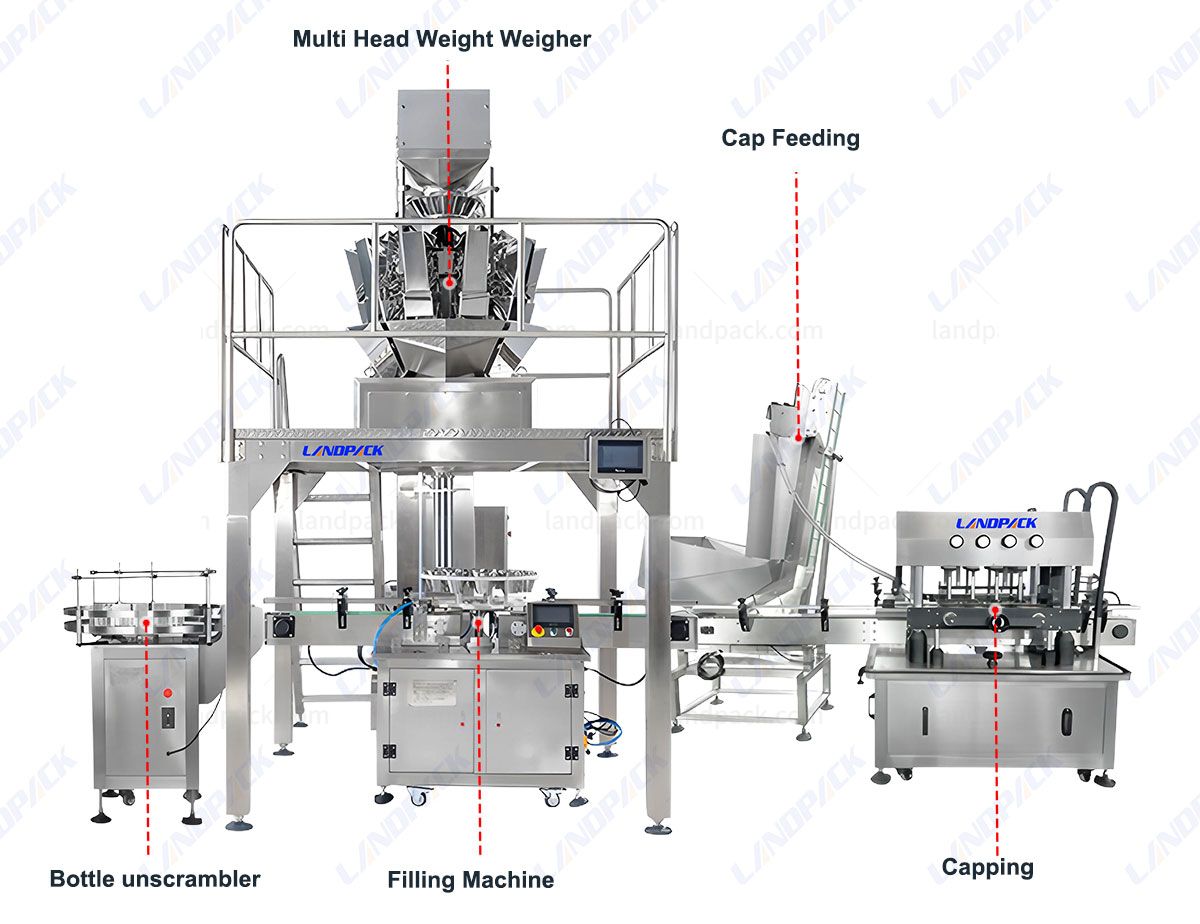

This fragrance beads filling line integrates automatic bottle unscrambling, precise granular filling, cap feeding and capping, labeling, and finished product output, making it suitable for a wide variety of free-flowing granular products packaged in bottles or jars. It is especially ideal for

Household & Laundry Care Industry: Scented laundry beads, fabric fragrance boosters, washing scent pearls, deodorizing beads, and long-lasting laundry aroma granules

Personal Care & Home Fragrance Industry: air-freshening beads, closet fragrance granules, room scent pearls, wardrobe deodorizer beads;

Food Industry: Sugar, Candy beads, Dry fruit, Flavored Salt Granules.

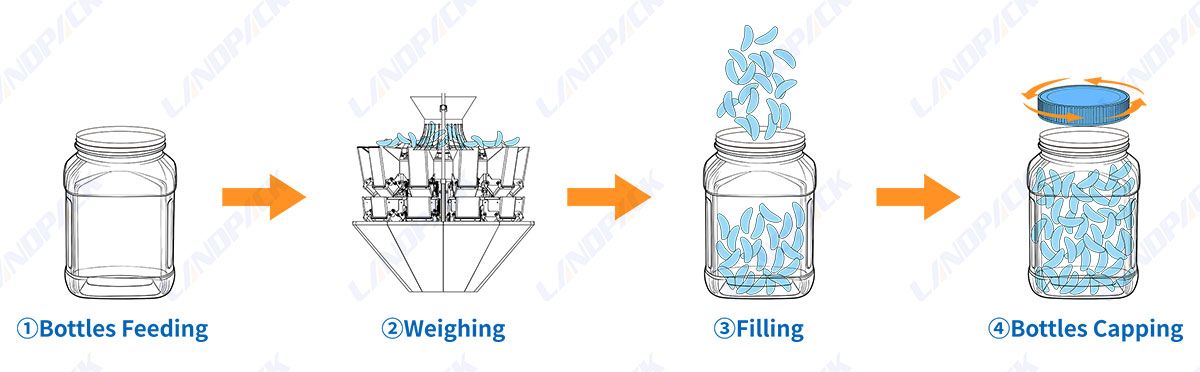

Workflow:

1. Bottle Unscrambling: Empty bottles are sorting automatically and arranged through the unscrambler for bottles. and then redirected in a sequential flow.

2. Product Feeding & Measuring: Fragrance beads and other products that are granular are put into the multi-head weighter.

3. Granule Filling: The rotary granular filling device accurately dispensing the measured product into bottles.

4. Capping: The bottles that are filled with product enter the automated capping and feeding system in which caps are fixed and tightly tightened.

5. Labeling: Bottles are taken into the labeling area for precise application of self-adhesive label.

6. Finished Product Collection: Bottles that have been refilled are transferred onto the tableor conveyor for inspection.