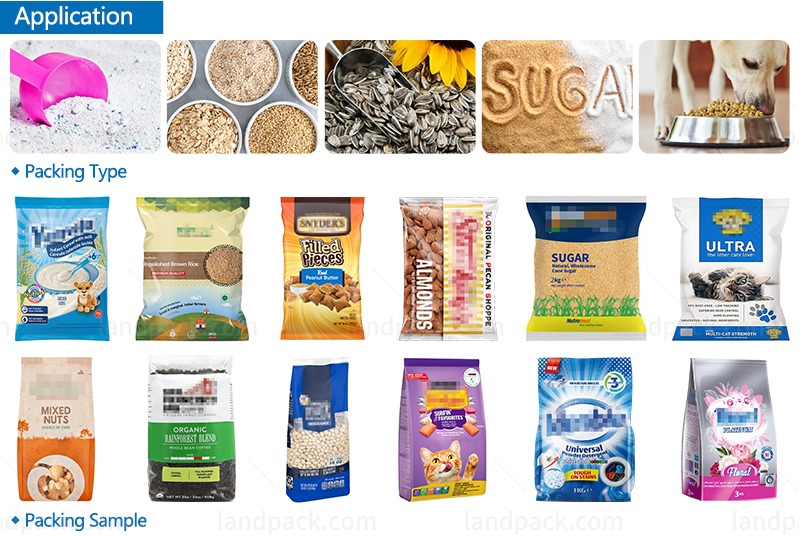

Application:

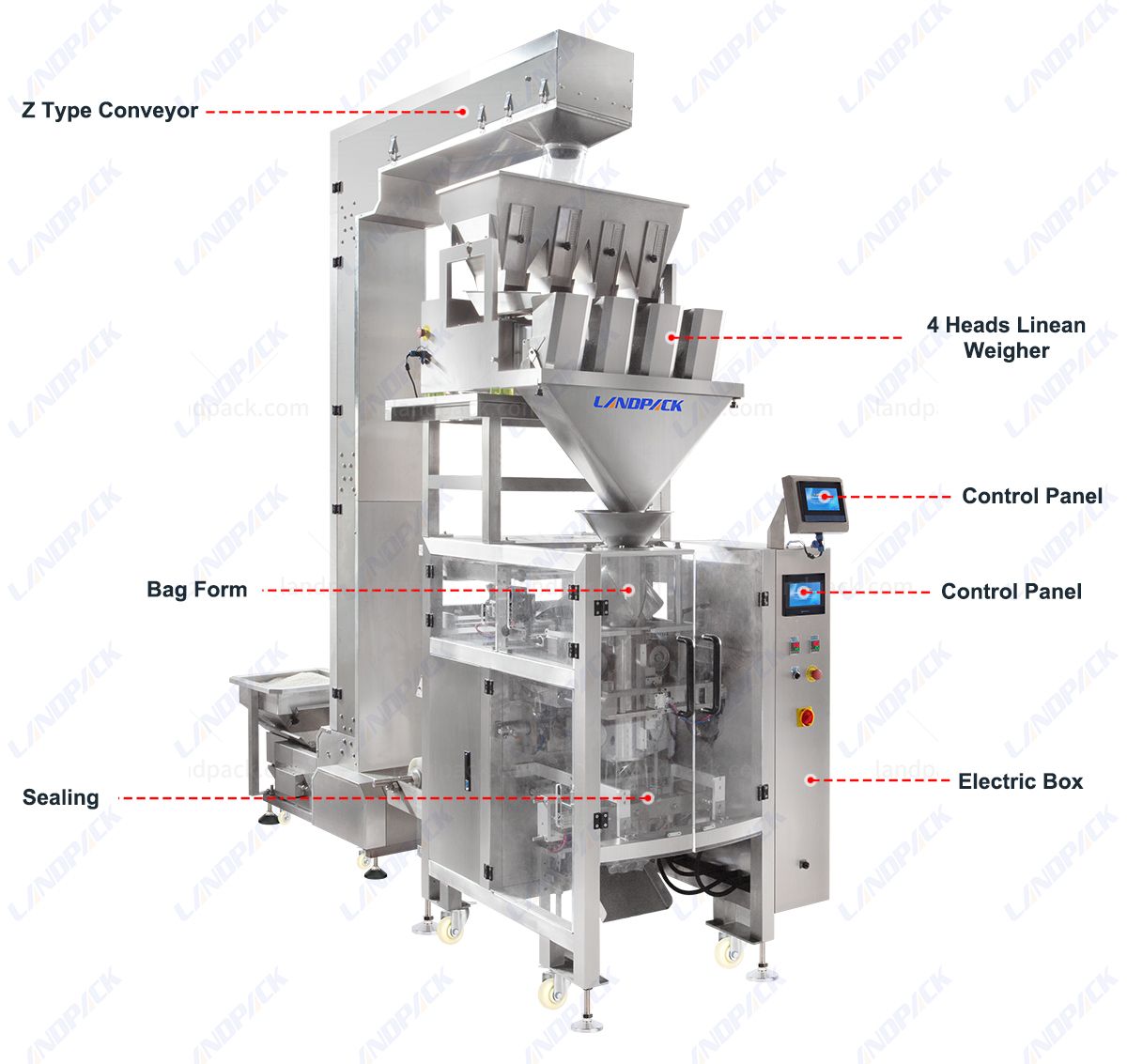

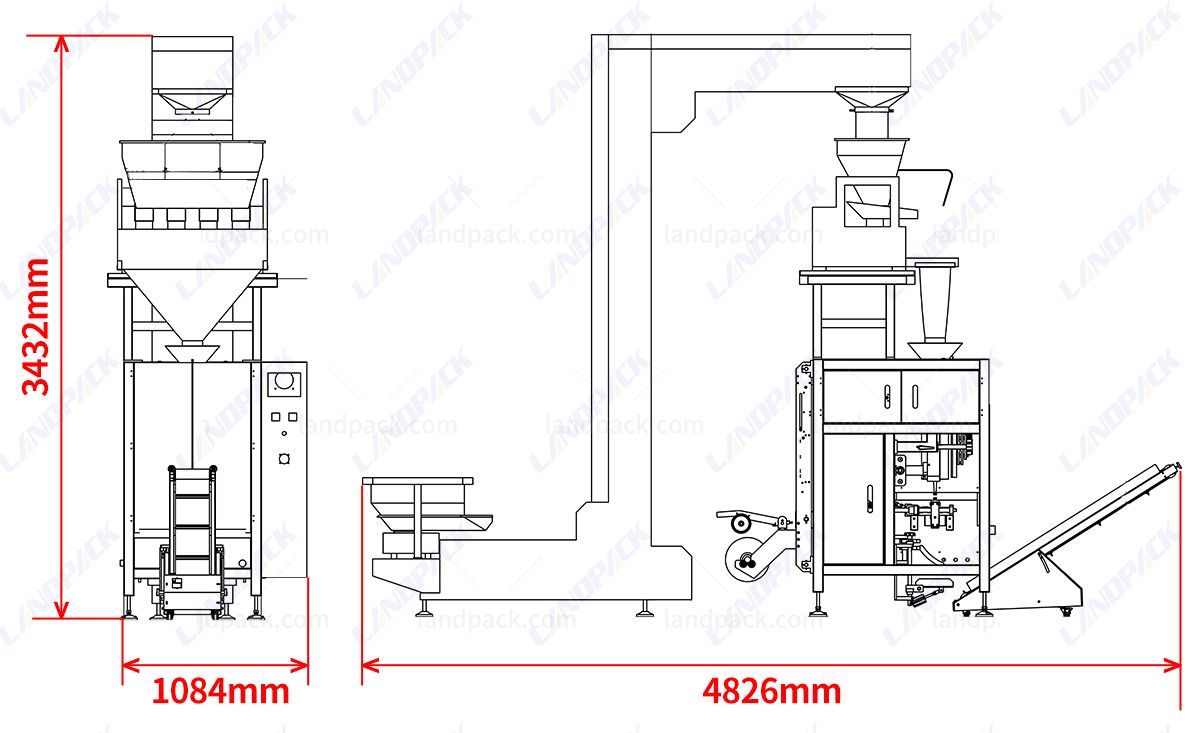

The LD-520AS Vertical Packing Machine with a 4-head linear weigher provides a high-precision automated packaging solution specifically designed for powders, granules, and other small-sized solid objects. This system guarantees accurate weights, efficient filling, and high-quality packaging. This makes it suitable for the food industry, household, and other sectors.

Packag Type:

This vertical packaging line supports multiple flexible pouch formats, including pillow bags, gusseted bags, quad seal bags, and insert corner bags, giving it excellent versatility for different product volumes and packaging requirements.

Suitable Products:

This packaging line is engineered to handle a wide range of free-flowing granular and small-piece materials with high accuracy and consistency. Its linear weigher ensures stable dosing, making it ideal for both food and non-food industries.

- Food Grains, Cereals & Agricultural Products: rice, wheat, lentils, beans, corn kernels, quinoa, millet, sesame seeds, rolled oats

- Snacks, Nuts & Small Dry Foods: almonds, peanuts, cashews, mixed nuts, dried fruits, puffed snacks, small crackers, pet treats

- Detergents, Chemicals & Industrial Granules: laundry detergent granules, dishwasher powder, fertilizer pellets, plastic granules, desiccant beads

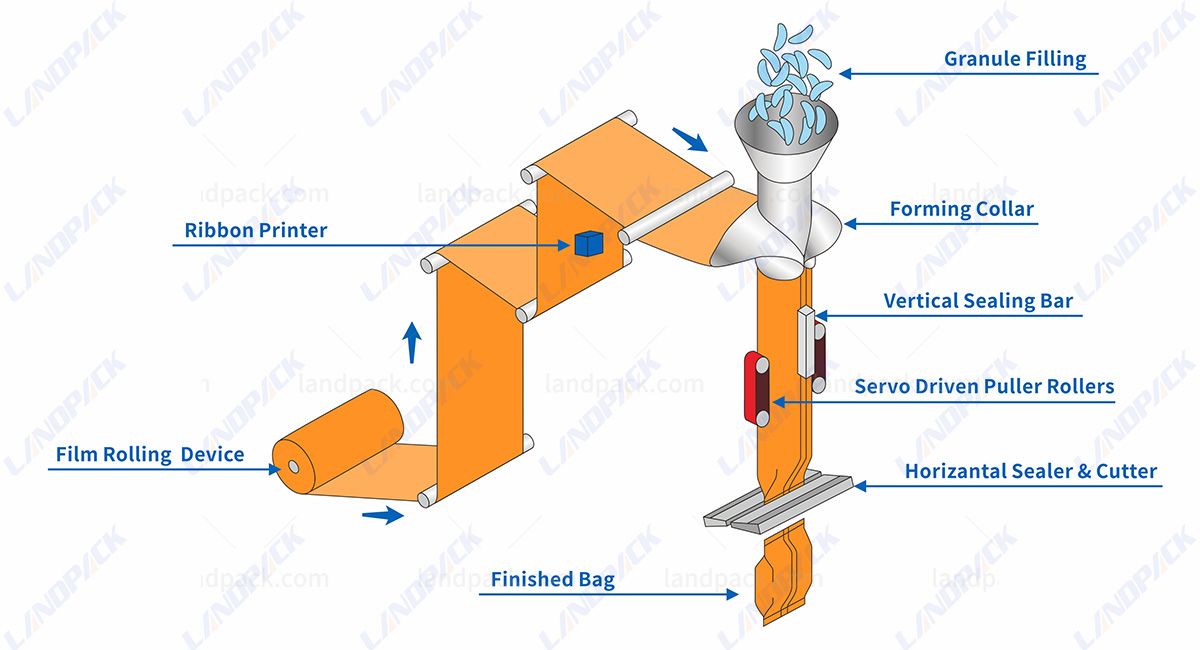

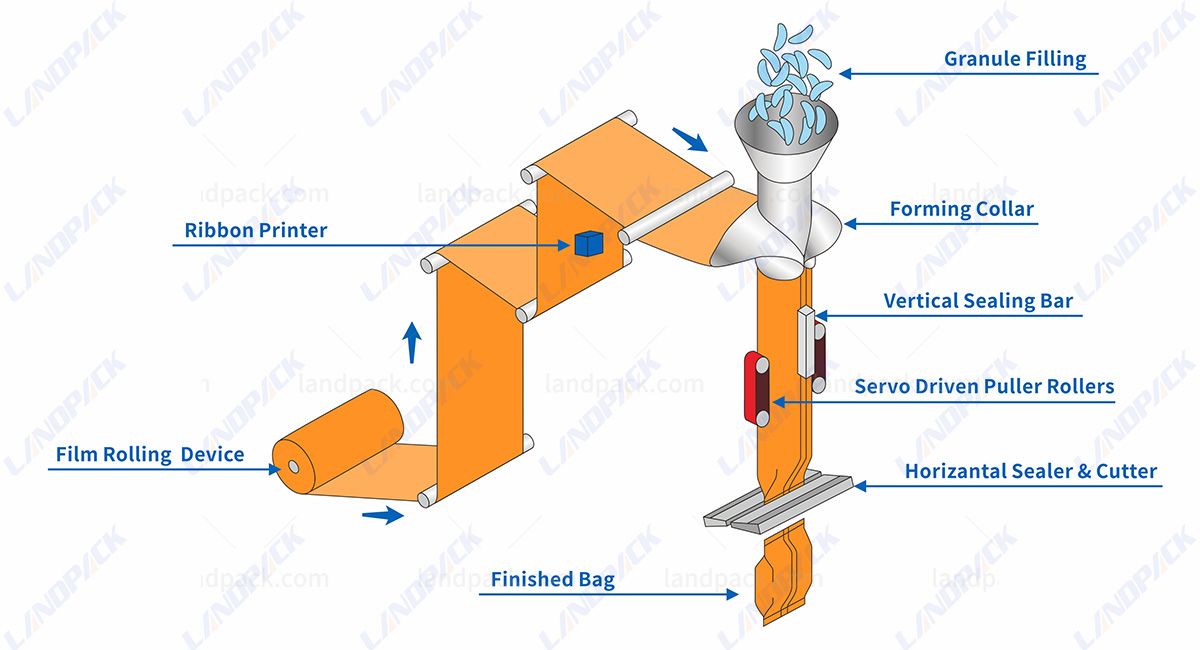

Workflow:

1. Material Feeding - Bulk products are transported to the Z-type elevator, which steadily lifts materials and feeds them into the linear weigher.

2. Accurate Weighing - The multi-head linear weighing system measures each portion precisely.

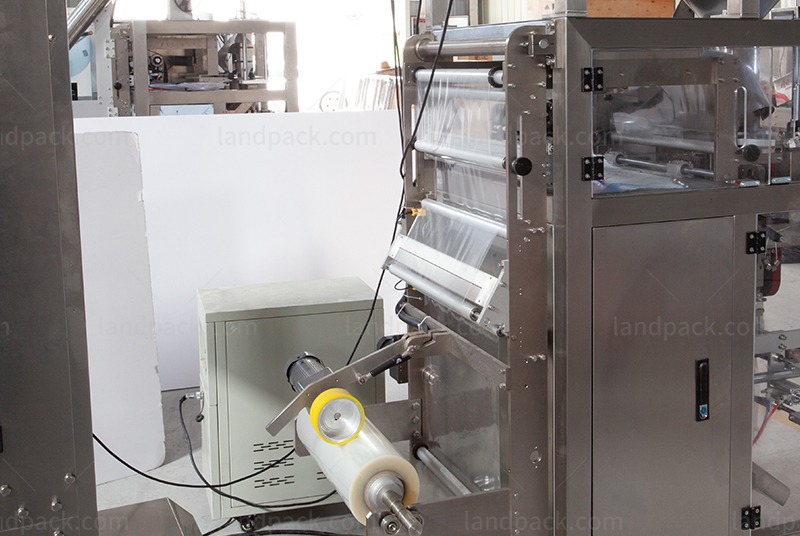

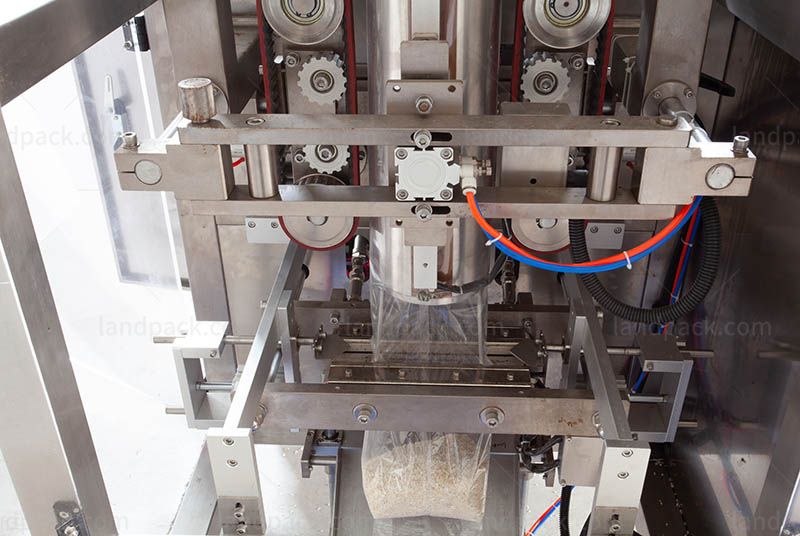

3. Pouch Forming - Film is unwound and shaped into bags by the forming collar.

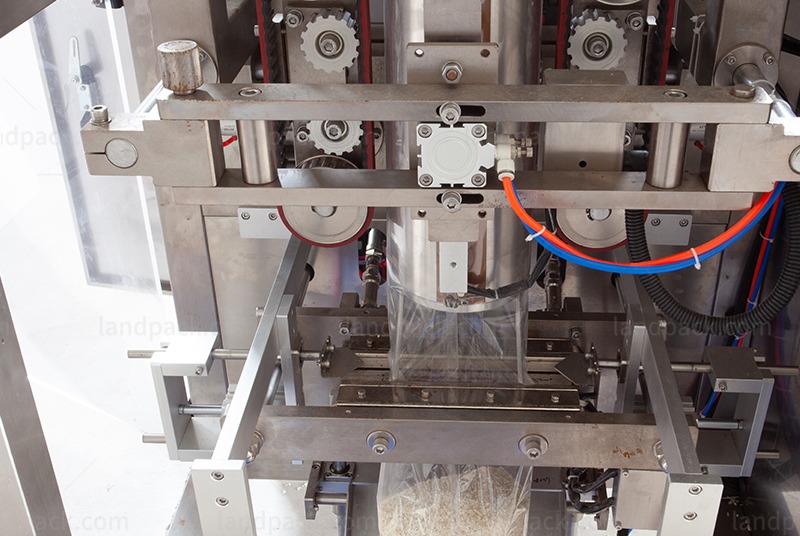

4. Product Filling - Weighed materials are discharged into the formed pouch through synchronized timing.

5. Top Sealing & Cutting - The horizontal sealing jaws close the pouch securely, followed by cutting to separate each finished pack.