Application:

Automatic Dry Fruit Raisin Packing Machine VFFS Packaging Machine is extensively used to pack different dry fruits and food products that are granular. It can be used to pack raisins, dried fruits and seeds, nuts, snacks, granules of snack mix, and other granules that flow freely. With a steady production of as many as 60 bags/min, this machine is perfect for food processing facilities or snack producers as well as manufacturers of packaging machines who require effective, precise and safe Food packaging machines.

Package Type:

This dry fruit packing machine is compatible with various bags formed from roll film, ensuring reliable sealing and neat appearance for high-speed production. Supported bag types include: pillow bags, back sealing bags, 3/4 sided seal bags. Suitable for laminated packaging films such as PET/PE, OPP/CPP, and other heat-sealable materials.

Suitable Products:

The VFFS automatic dried fruit packaging machine has been made to ensure accurate and reliable packing of granules that flow freely across the snack and food industries. It is capable of handling a broad range of dried fruit, nuts, snacks and grains that have a consistent weighing performance as well as easy bag making which makes it suitable for commercial production at high speed.

Suitable materials include:

- Dried Fruits & Nuts: Raisins, cranberries, dried blueberries, mixed nuts

- Snacks & Confectionery: Chocolate chips, cereal bites, small candies, fruit gummies

- Grains & Pulses: Rice, lentils, beans, quinoa

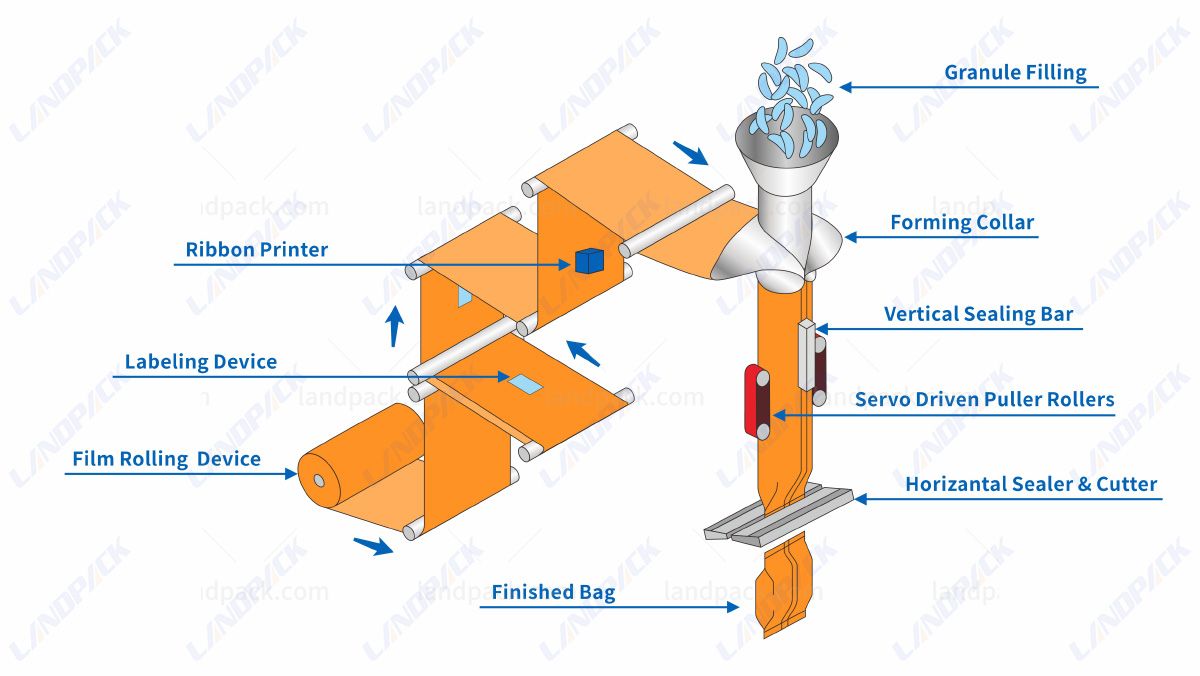

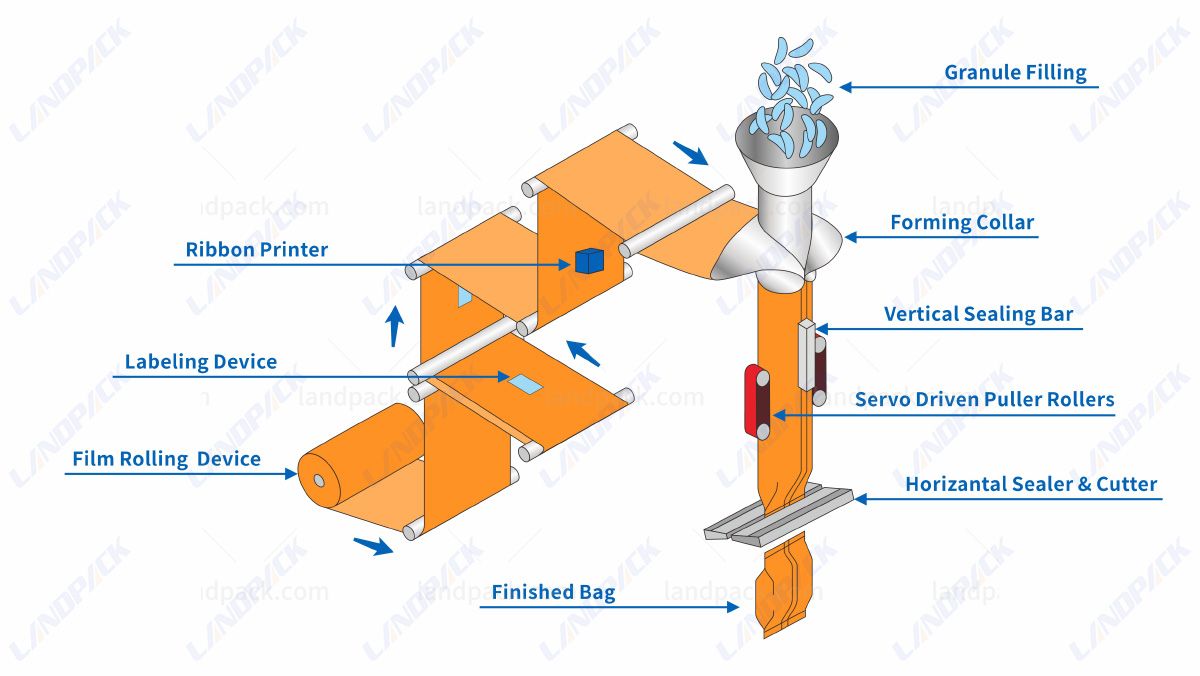

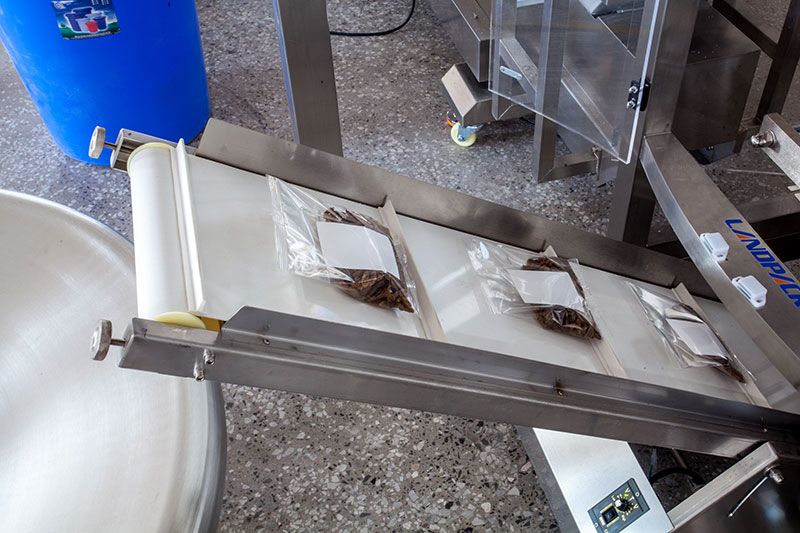

Workflow:

1. Film Unwinding – Packaging film is released smoothly from the film rolling device.

2. Printing & Labeling – Date/lot code is printed by the ribbon printer, while labels can be applied inline if required.

3. Bag Forming – Film passes through the forming collar to shape a vertical pillow bag.

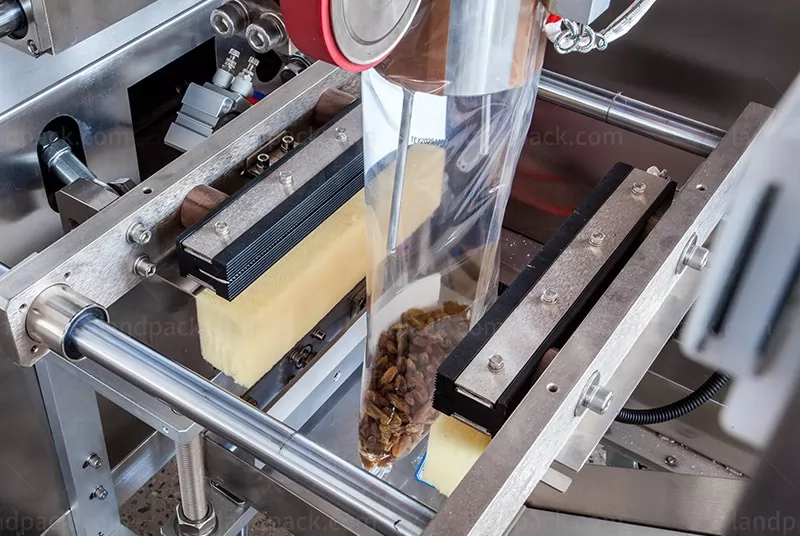

4. Granule Filling – Granule products are accurately filled into the formed bag from the filling system.

5. Vertical Sealing – The vertical sealing bar creates a strong back seal.

6. Film Pulling – Servo-driven puller rollers ensure stable film movement and precise bag length.

7. Horizontal Sealing & Cutting – Top and bottom seals are made, and bags are cut individually.

8. Finished Bag Output – Completed bags are discharged smoothly for the next process.