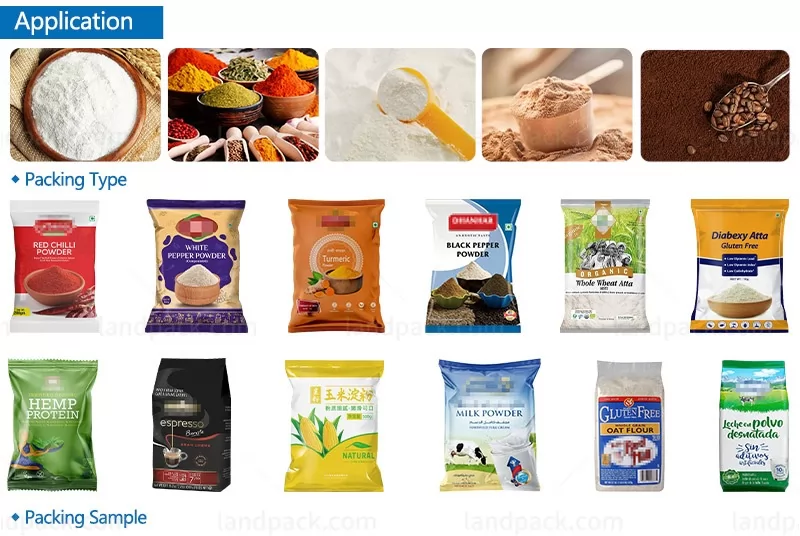

Application:

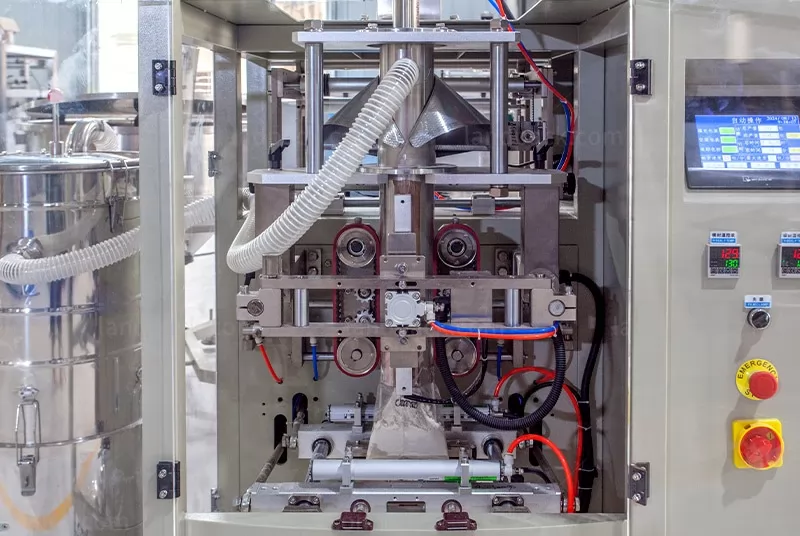

This Automatic Flour Packing Machine, Also Known as a Vertical Powder Packaging Machine, is specifically designed to provide precision and high-speed packaging of various powders in up to 60 bags/min. It is extensively utilized for cereal flours, wheat flour, tapioca flour, rice flour and seasoning powders, as well as starch baking powders, cocoa powder, protein powder, nutritional powders as well as other small chemical powders. Perfect for food processing facilities as well as powder production lines, this machine guarantees precise, clean and efficient filling of powders and sealing of various types of pouches.

Package Type:

This automatic flour packing machine is compatible with a wide range of powder pouch formats, ensuring stable forming, clean sealing, and high-speed packaging for different market needs. It supports Back Seal (Center Seal) Bags, 3/4 Side Seal Bags, Gusset Bags, etc.

Suitable Products:

This Automatic Flour Packing Machine is specifically designed to provide efficient and precise packaging of a variety of powders from industries like food, chemical industrial, agricultural, and industries. It provides the safest filling and sealing and fast operation for both medium and fine density powders.

- Food & Beverage Powders: Flour & Starch, Seasoning Powders, Milk Powder, Coffee Powder

- Home Care & Daily Chemical Powders: Laundry Detergent, Bleaching Powder, Fragrance Powder, Enzyme Powders

- Industrial & Agricultural Powders: Fertilizer Powder, Construction Additive Powders, Mineral Powders, Fine Industrial Powders

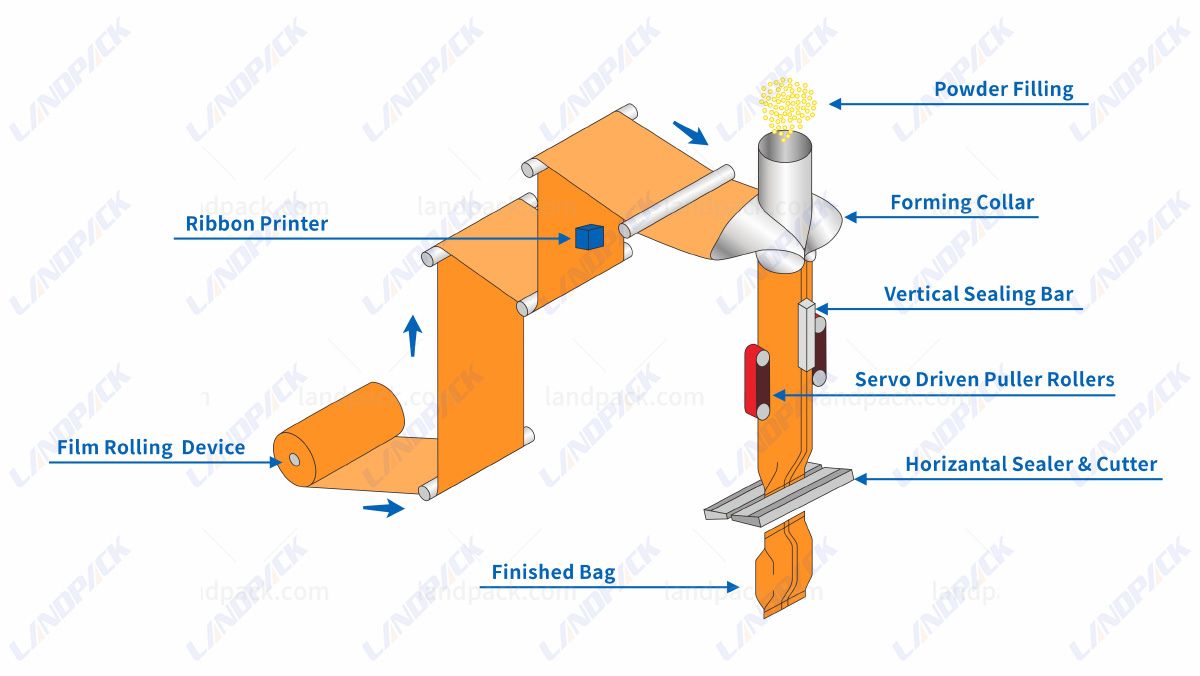

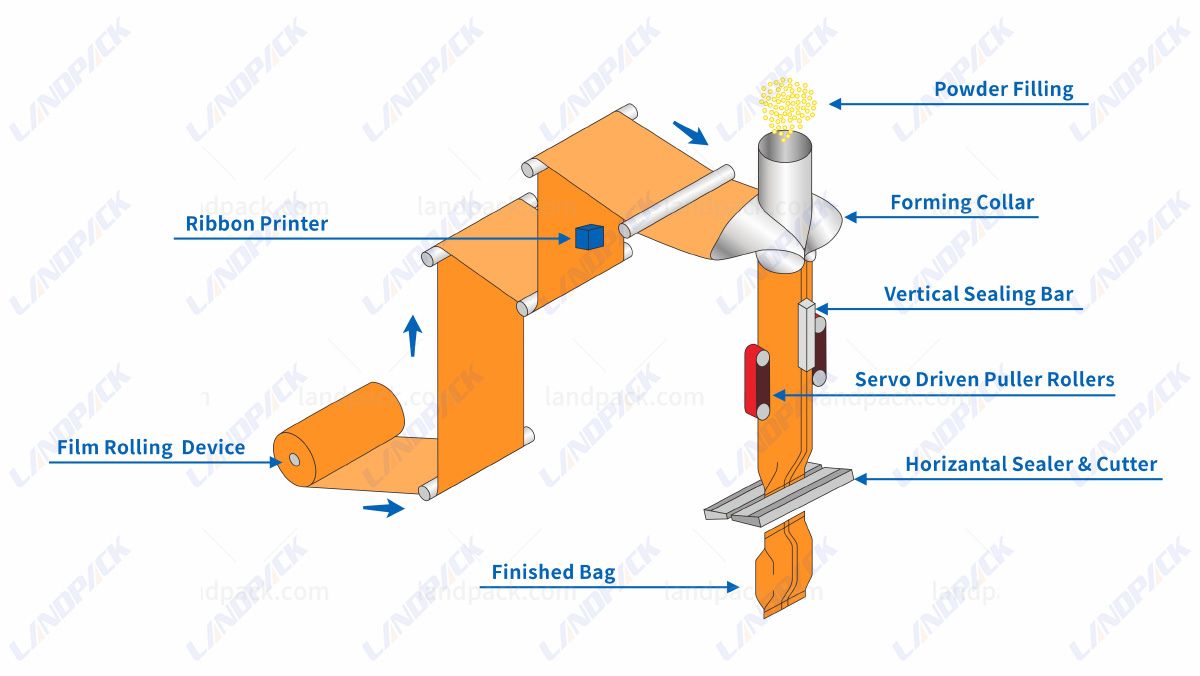

Workflow:

1. Film Rolling Device: The packaging film is automatically unwound from the film roll and guided smoothly into the forming system.

2. Ribbon Printer: Prints production dates, batch numbers, or codes onto the film before the bag is formed.

3. Forming Collar: The flat film is shaped into a tube as it passes through the forming collar.

4. Vertical Sealing Bar: Creates the vertical (back) seal to form the pouch tube.

5. Powder Filling: Powder materials are accurately dispensed into the formed tube through the filling funnel.

6. Servo-Driven Puller Rollers: Pull the film downward steadily to ensure stable bag forming and consistent bag length.

7. Anti-Static Devices: Reduce powder adhesion on the film surface and machine parts.

8. Horizontal Sealer & Cutter: Seals the top and bottom of each bag and cuts them into individual finished pouches.

9. Finished Bag Output: The completed, sealed powder bags are discharged and ready for packing or conveying.