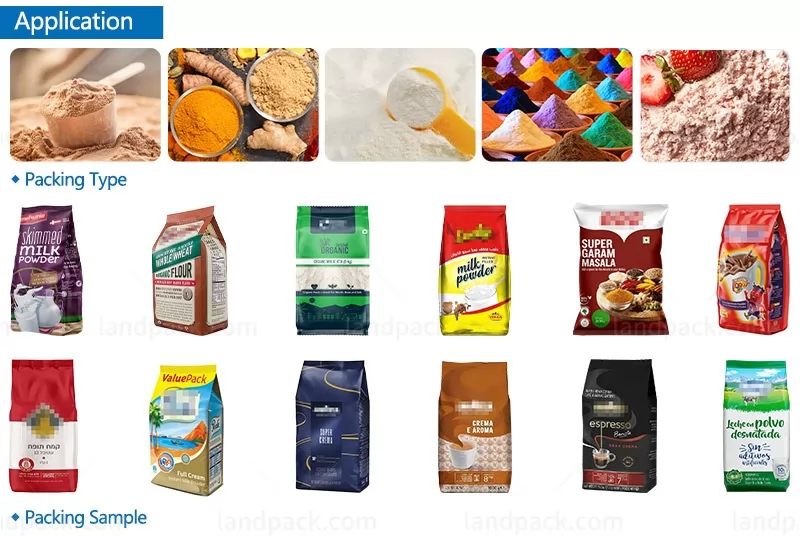

Application:

The Vertical Automatic Flour Packaging Machine is designed for fast and accurate powder packaging such as wheat flour, corn flour, rice flour, starch, baking powders, and other fine food-grade powders. It is widely used in food processing plants, flour mills, bakery ingredient factories, and powder production lines requiring stable dosing, clean sealing, and continuous high-speed vertical packaging.

Package Type:

Compatible with a wide range of powder packaging formats, ensuring flexibility for different market needs: gusset bag, pillow bag, back sealing bag, and other standard powder packaging bags.

Suitable Products:

The machine is designed for the precise packaging of powders. This machine can handle many different chemical, food and industrial powders.

- Food & Beverage powders: starch and flour, seasoning powder, spice powders and milk powder, coffee powder

- Home Care & Daily Chemical Powders: Laundry detergent, bleaching powder, fragrance powder, enzyme powders

- Industrial & Agricultural Powders: Fertilizer powder, construction additive powders, mineral powders, fine industrial powders

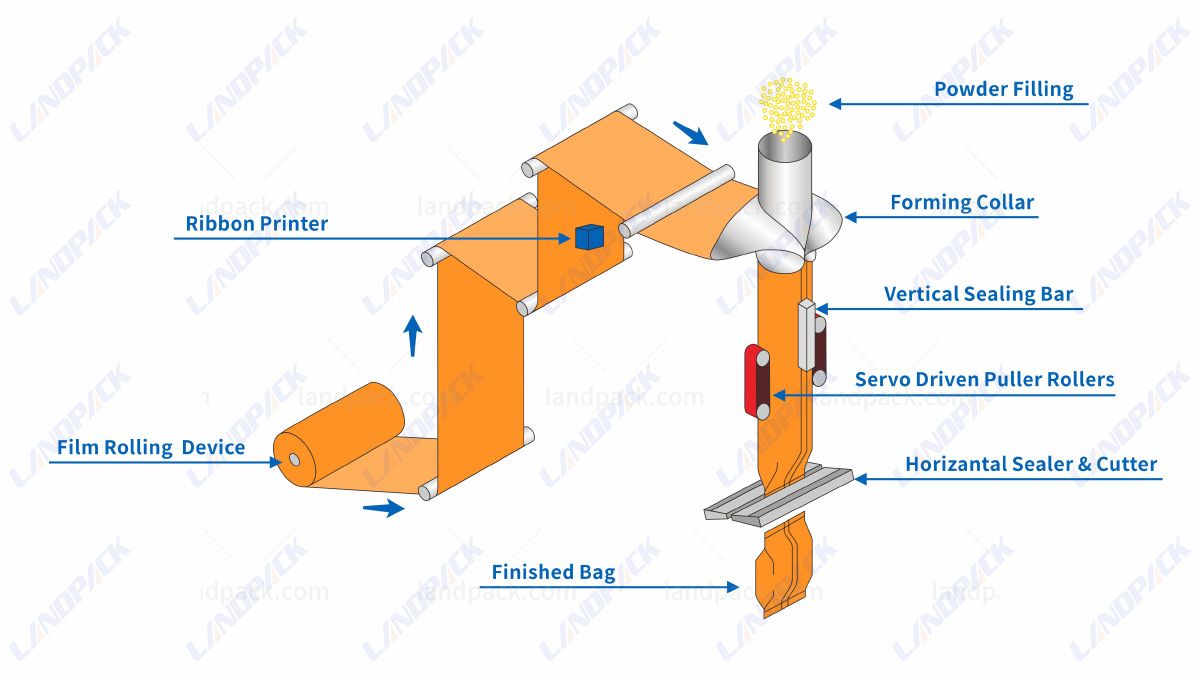

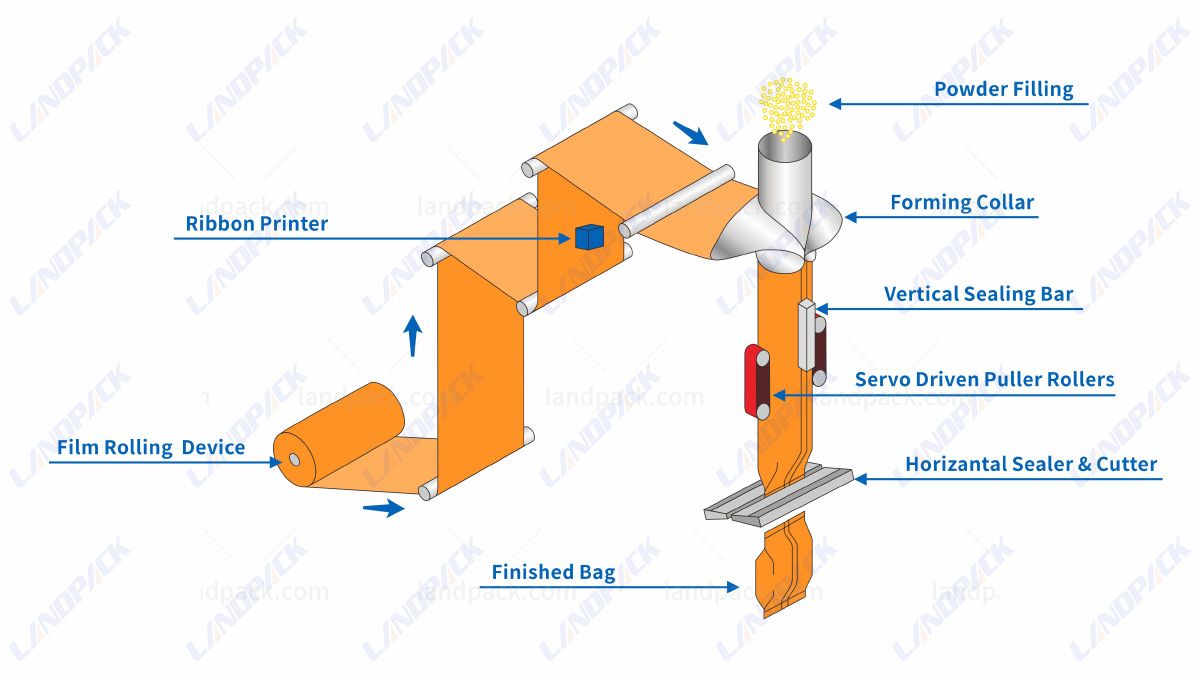

Workflow:

1. Film Rolling Device - Holds and releases the film roll smoothly for continuous production.

2. Ribbon Printer - Prints date, batch number, or logo on the film before forming.

3. Powder Filling - Screw dosing system accurately measures and dispenses powder into the forming tube.

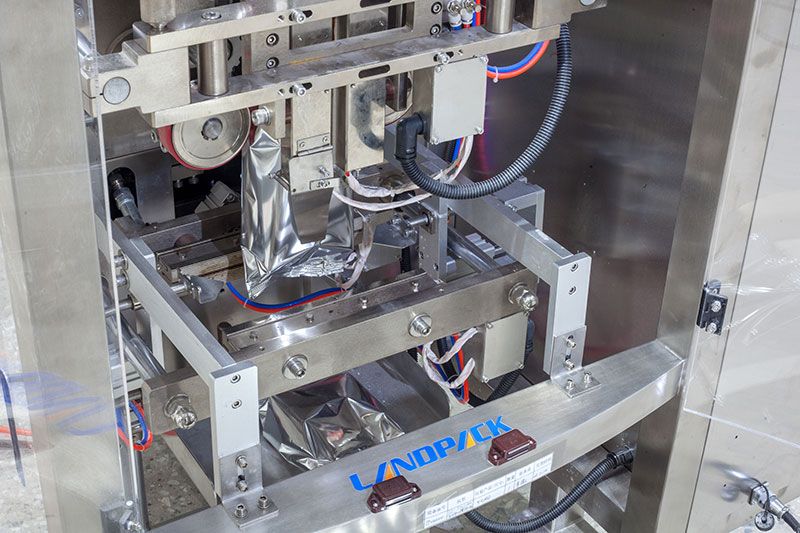

4. Forming Collar - Shapes the film into a tubular bag structure.

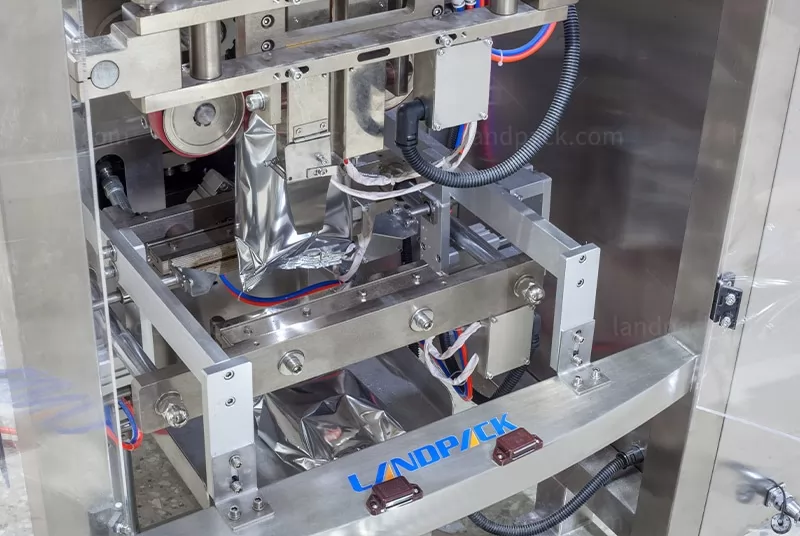

5. Vertical Sealing Bar - Creates the back sealing seam to form the bag body.

6. Servo Driven Puller Rollers - Pull the film precisely to ensure stable bag length.

7. Horizontal Sealer & Cutter - Seals the top and bottom of each bag and cuts them into individual units.

8. Finished Bag - Neatly discharged ready for further inspection or packing.