1. Tailstock: Made of 304 stainless steel, dual-channel servo individually controls the feeding, high efficiency; each channel adopts double push finger conveying, and the feeding is more stable.

2. Film unwinding mechanism: adopts two-axis film unwinding, which is suitable for different packaging materials at the same time, such as aluminum-plastic, paper-plastic, etc., independently controlled by each motor, and the film unwinding tension is more stable.

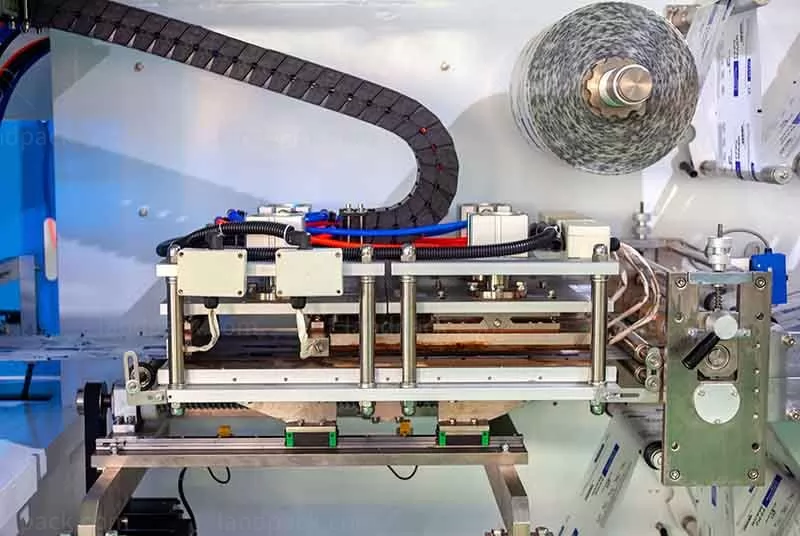

3. Heating sealing mechanism: Servo frequency tracking reciprocating control is adopted to improve the efficiency of heat sealing and sealing. The sealing adopts an adjustable structure, which can adjust different bag widths appropriately. It adopts five temperature control controls to independently adjust the sealing of each edge. The combined temperature makes the sealing edge more beautiful.

4. Slitting mechanism: It adopts an independent slitting mechanism, which can adjust different slitting widths. It adopts servo control synchronously with the rear traction mechanism. The slitting blade is made of high-speed steel and is wear-resistant.

5. Electric box control system; adopts full servo control system (tail plus-front traction-heat sealing-slitting / rear traction-cutting-finished product conveying), PLC adopts bus electronic cam control, suitable for controlling multi-axis synchronous motion control The system is more precise than the traditional pulse ice control.