Wide application range, can meet the full-circle labeling or semi-circle labeling of round bottles, easy to switch labeling between bottles, easy to adjust;

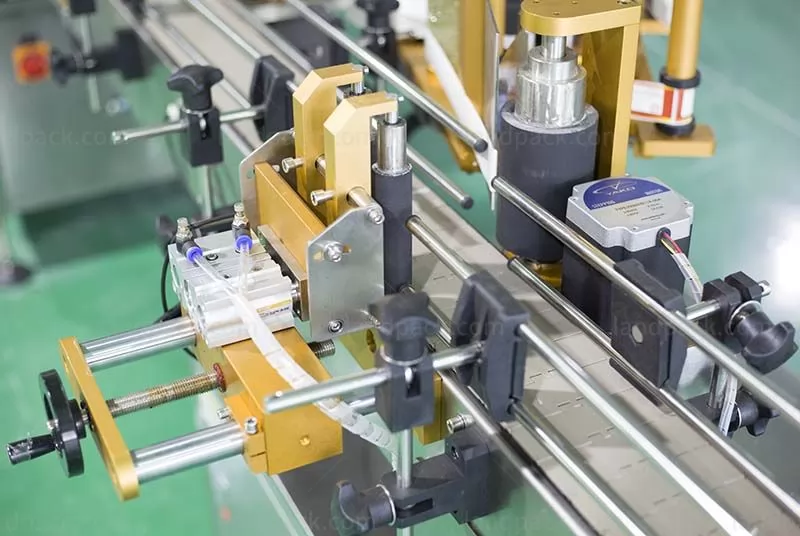

The label has a high degree of coincidence. The label is bypassed by a rectifying mechanism. The label is not deflected. The labeling position is x/y/z and the inclination is adjustable. The total of eight degrees of freedom is adjustable.

Excellent labeling quality, adopting elastic pressure-coated belt, flat labeling, no wrinkles, and improve packaging quality;

Flexible application, bottle standing labeling, automatic bottle splitting function, can be produced in a single machine, or can be connected to the production line;

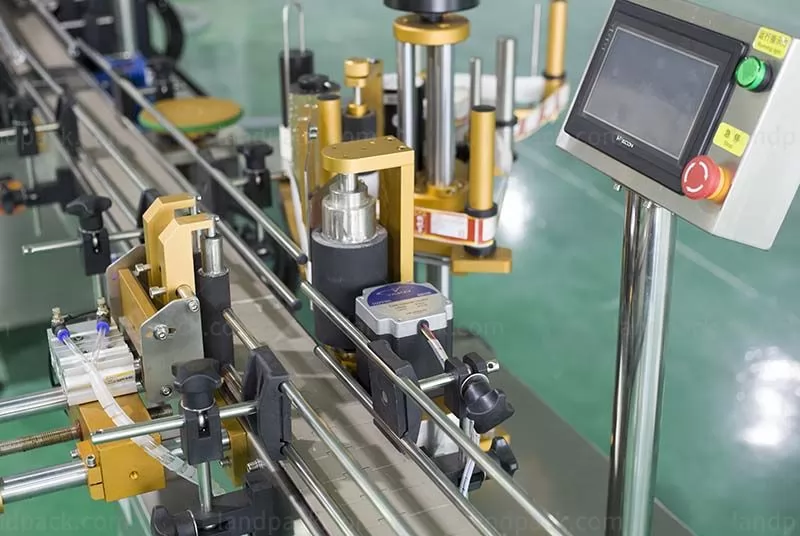

Intelligent control, automatic photoelectric tracking, with no material and no labeling, no automatic calibration and automatic label detection to prevent leakage and label waste;

High stability, Panasonic PLC + Panasonic touch screen + Panasonic needle-shaped electric eye + German labor test label electric eye composed of advanced electronic control system, support equipment 7 × 24 hours of operation;

Simple adjustment, labeling speed, conveying speed and bottle dividing speed can realize stepless speed regulation and adjust according to need;

Rugged and durable, adopting three-bar adjustment mechanism to make full use of the stability of the triangle, the whole machine is solid and durable. Made of stainless steel and high-grade aluminum alloy, in line with GMP