Application:

With its accurate 10-head combination weigher and smooth pouch handling design, it is widely used for packaging macaroni, penne, fusilli, and other pasta types, as well as cereals, nuts, beans, dry snacks, pet food pellets, and similar granular products.

Package Type:

The LDSP-210A packing machine supports lots of pouch types—including M shape pouch, stand-up pouch (doypack), zipper pouch, and other premade pouch—making it highly adaptable to different packaging needs. With these versatile bag types, the machine can efficiently handle nut, dry fruit and various granular foods.

Suitable Products:

The LDSP-210A Pouch Packaging Machine, with its gentle product conveying, hygienic structure, and compatibility with irregular-shaped dry foods, the packing machine is widely used across various food industries.

- Pasta & Grain Products: macaroni, penne, fusilli, elbow pasta, rice snacks

- Cereals & Breakfast Foods: corn flakes, oat crisps, granola clusters

- Snacks & Dry Foods: nuts, dried beans, popcorn kernels, baked snacks

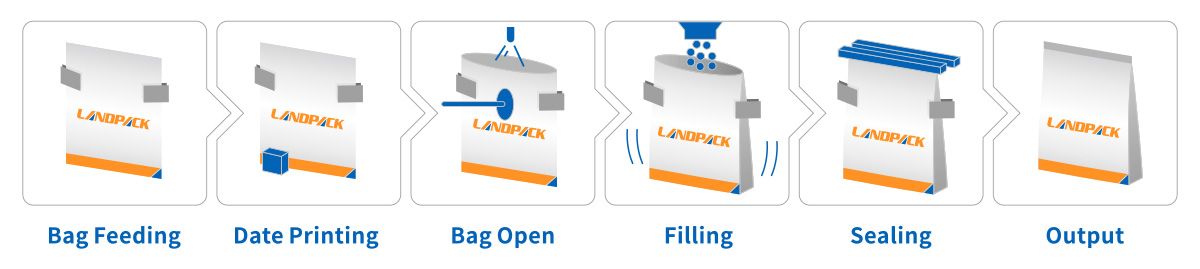

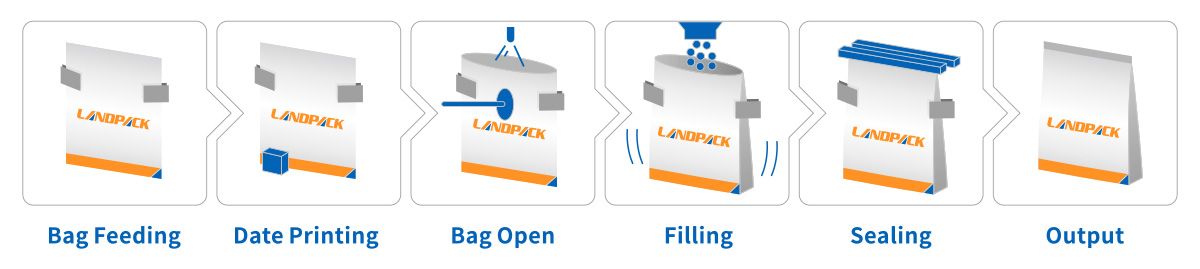

Workflow:

This is automatic m shape pouch packing machine for granule products. Here's how it works step-by-step:

1. Product Feeding (Z-type Elevator) – product is gently lifted from the bulk hopper by the Z-type elevator, which delivers a steady, dust-minimized feed into the combination weigher.

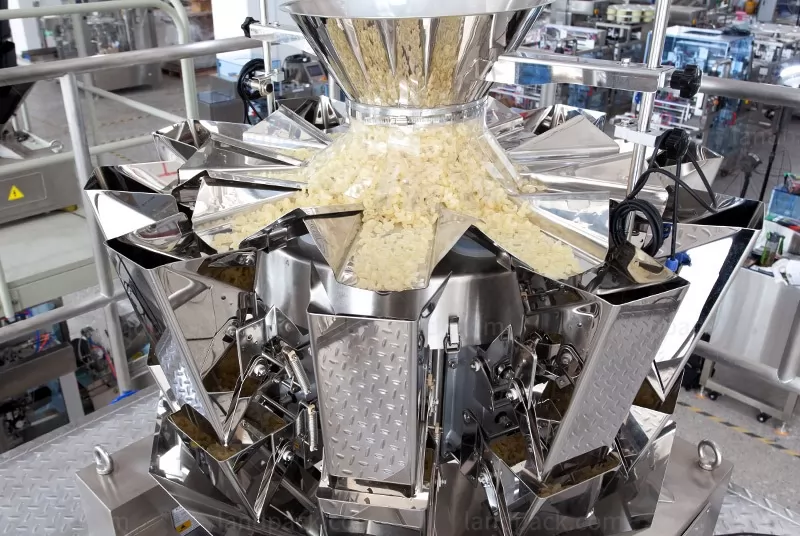

2. Accurate Weighing (10-Head Combination Weigher) – The ten heads work in coordinated cycles to rapidly and precisely dose the target weight for each pack.

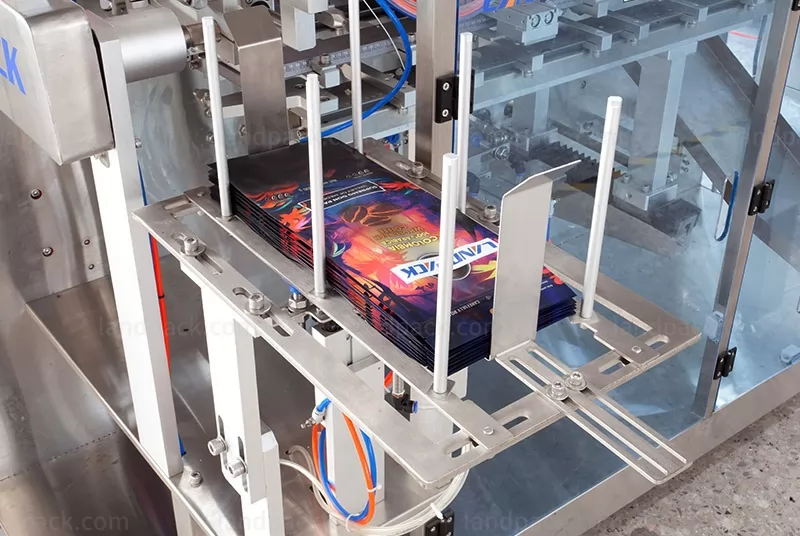

3. Pouch Feeding (Premade M shape Pouch Loading) – Premade M-shaped pouches are picked from the feeder and transferred into position on the machine by the pouch pick-and-place system.

4. Pouch Opening – Each pouch is mechanically opened and held by grippers while sensors verify a correct open state.

5. Filling – The measured products are dropped into the opened M shape pouch through a short, anti-splash filling hopper.

6. Sealing, Coding & Inspection – After filling, the pouch top is sealed, then passes under the inkjet coder for batch/date printing.

7. Finished Product Discharge – Sealed pouches are conveyed out smoothly to the output conveyor or collection table.