Application:

High accuracy mini doypack packaging machine counting packing machine designed for secondary packaging. This compact single-station machine ensures precise counting, stable performance, and efficient bagging. Perfect for product packing into premade pouches with a speed of 15 bags/min.

Suitable Products:

The Mini Doypack Packaging Machine is widely used for secondary packaging of small portioned items into premade zip lock bag or doypack. It is suitable for a wide range of industries:

* Food Products: Tea leaves, instant coffee sachets, sugar & salt packs, spices & seasonings, herbal tea bags.

* Daily Products: Laundry pods, bath salts, shampoo samples, lotion sachets, wet wipes.

* Others: Pet food snacks, agricultural seeds, health supplement powders, chemical granules, desiccant packs.

This machine ensures accurate counting, clean bag filling, and reliable sealing, making it an ideal choice for companies seeking neat and efficient pouch packaging.

Package Type:

The Mini Doypack Packaging Machine is compatible with a wide range of premade pouch types, including zip lock bags, stand-up pouches, M-shape gusset bags, and other customized pouch styles. These flexible packaging options not only ensure excellent product protection but also provide strong shelf appeal and convenience for resealing, displaying, and storing different food, daily products, and industrial goods.

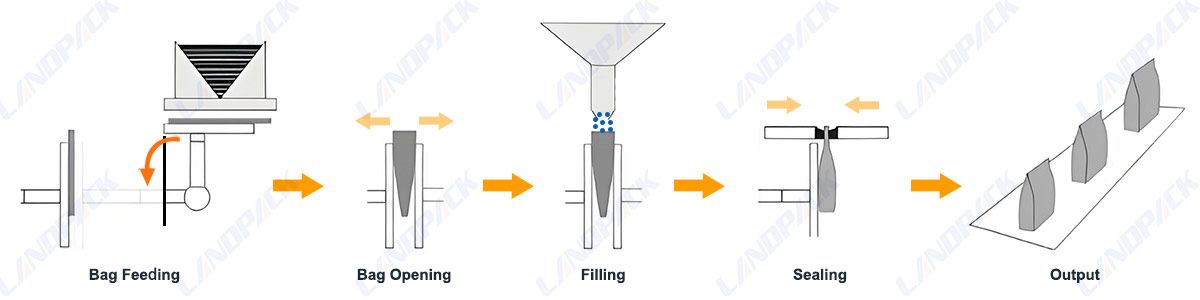

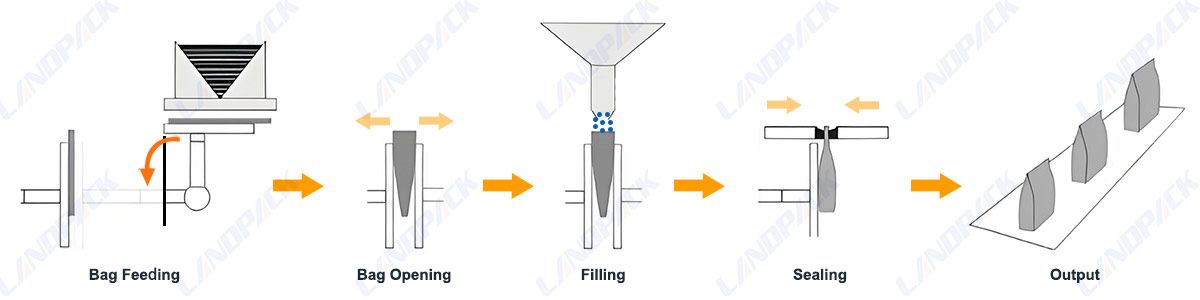

Workflow:

The working process of the Mini Doypack Packaging Machine is simple and efficient:

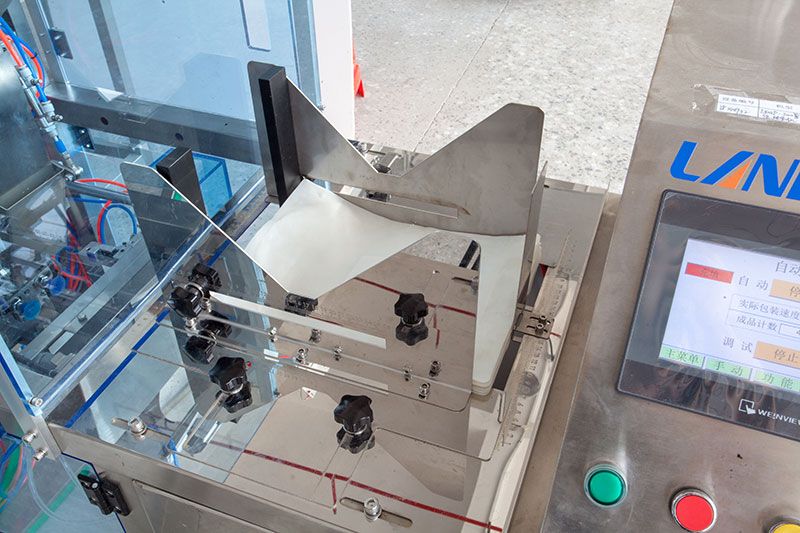

1. Bag Feeding – Premade pouches are placed into the machine and automatically fed to the next station.

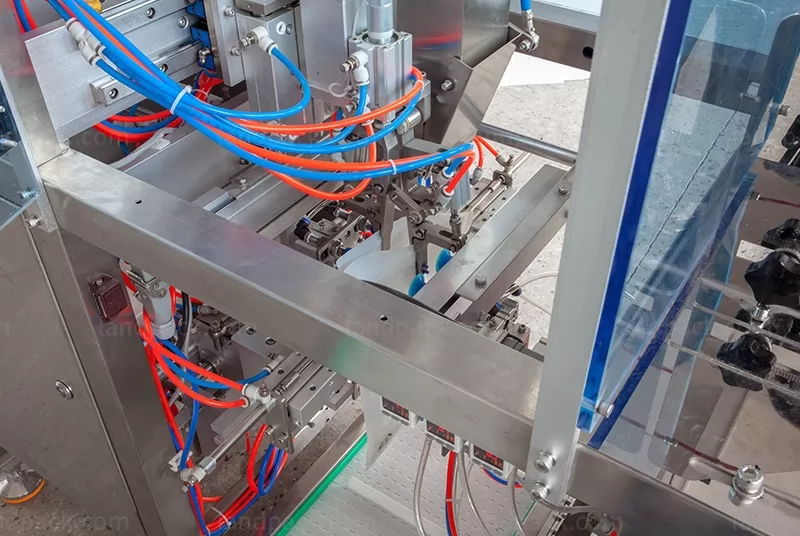

2. Bag Opening – The machine gently opens the pouch, getting it ready for filling.

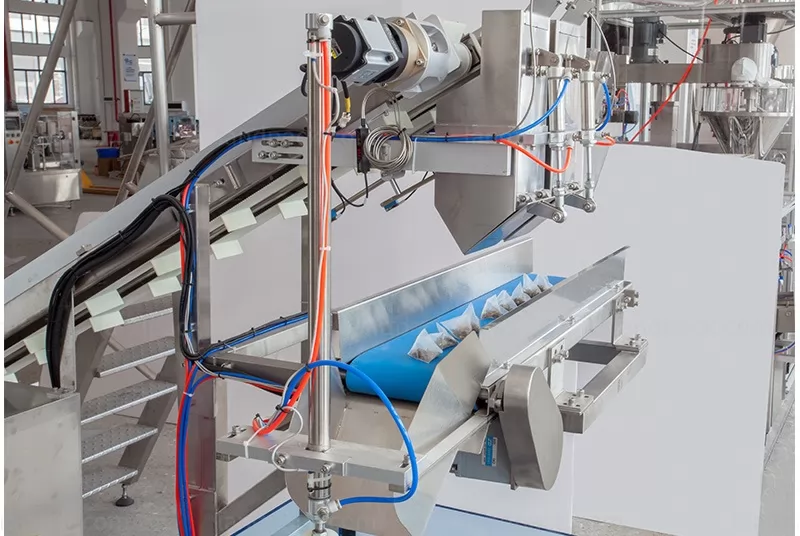

3. Filling – Product is accurately dispensed into the pouch through the filling system.

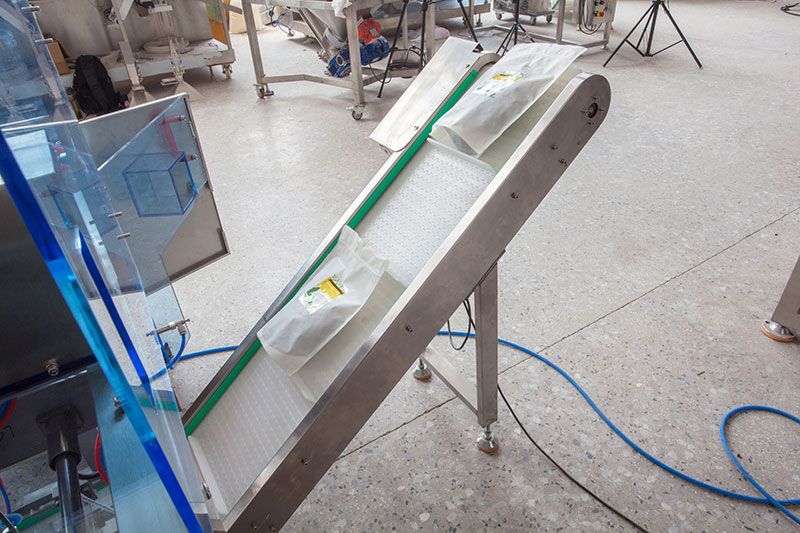

4. Sealing – The pouch is sealed to preserve freshness and stop leakage.

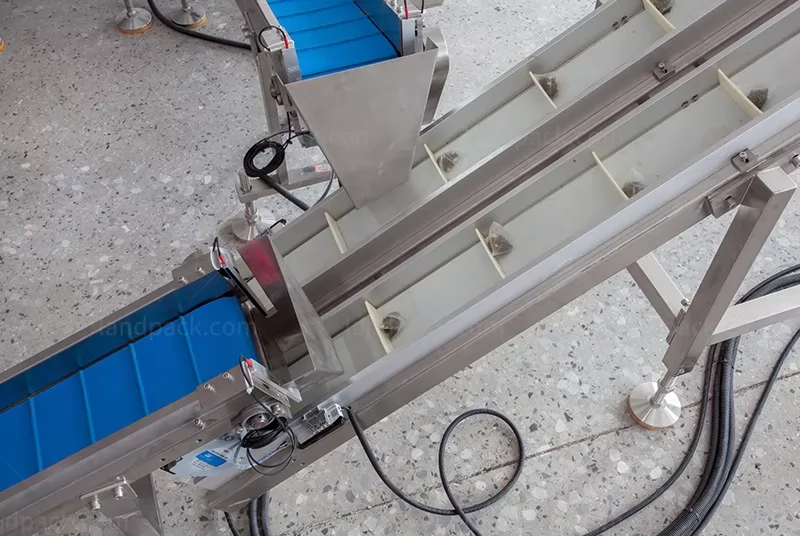

5. Output – The finished packages are sorted and delivered on the conveyor at the output point ready for packaging or other handling.