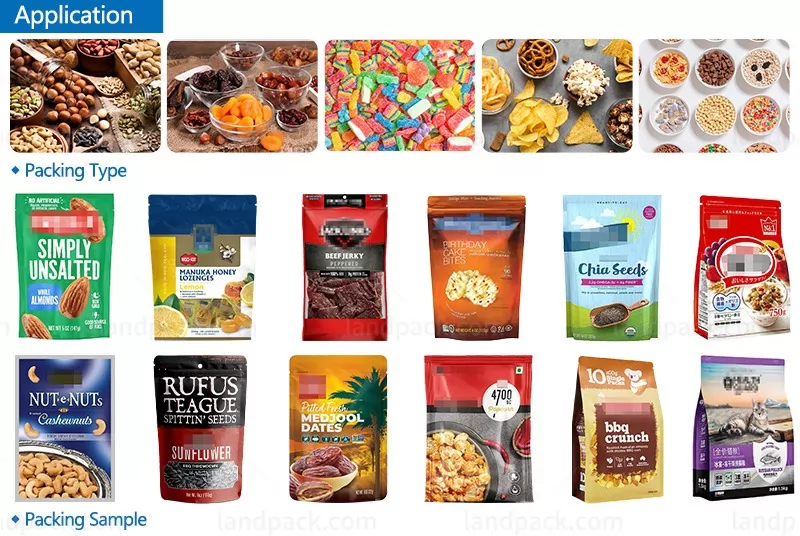

Application:

This doypack pouch packing machine is fast, clean, and efficient, handling various granular products with ease. It works with stand-up zipper pouches at speeds of 20–50 bags/min, ensuring accurate filling and reliable sealing. Perfect for food, nuts, seeds, and other granular industries, it helps increase output, reduce waste, and keep products fresh.

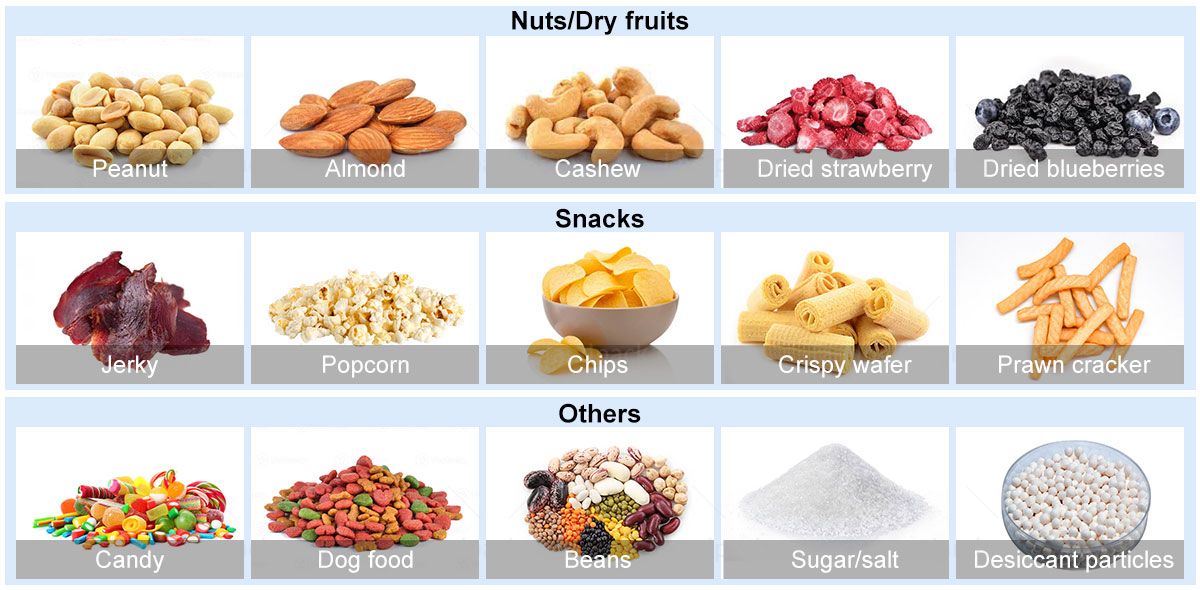

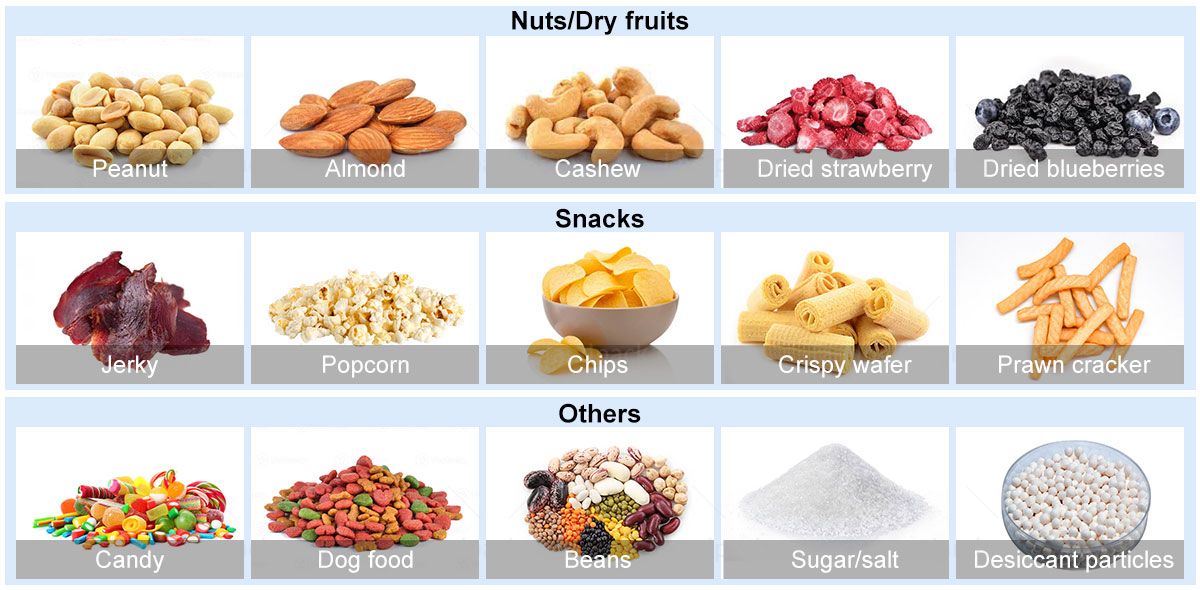

Wide Application for Various Products:

* Nuts & Dry Fruits: Perfect for a wide range of natural and healthy products, such as almonds, cashews, peanuts, walnuts, pistachios, raisins, dried apricots, dried cranberries, and mixed dry fruit blends.

* Snacks: Ideal for everyday snack packaging, including chips, popcorn, puffed snacks, biscuits, cookies, candies, and chocolate bites.

* Others: Versatile for many other granular or small-sized products, whether food or non-food, such as coffee beans, tea leaves, sugar, rice, seeds, pet food, detergents, and desiccant granules.

Flexible Bag Styles:

* Stand-up Pouch: Strong bottom support, perfect for display on shelves, widely used for nuts, coffee, and snacks.

* M-shape Pouch: Expands to hold larger volumes while keeping the pouch compact and stable.

* Flat Pouch: Simple and cost-effective solution for single-serve or small-portion products.

* Zipper Pouch: Resealable design for freshness and convenience, ideal for dried fruits, seeds, or pet food.

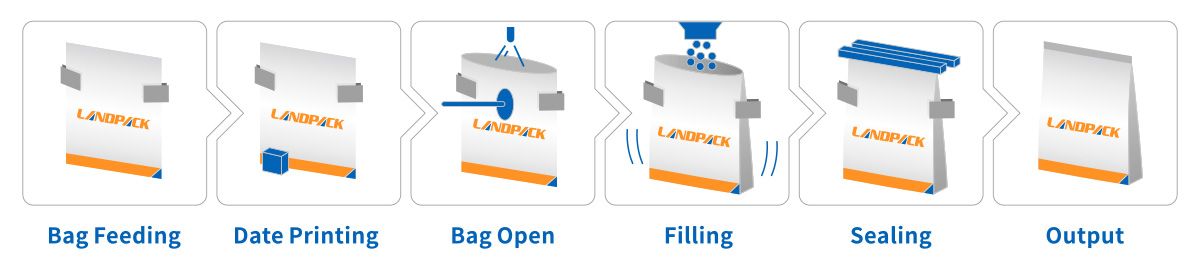

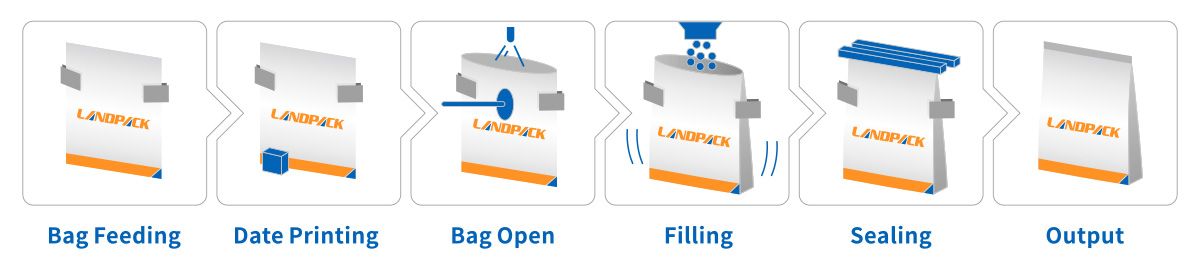

Workflow:

This automated granule doypack packing machine is ideal for packaging food and other granular products. Here's how it works step-by-step:

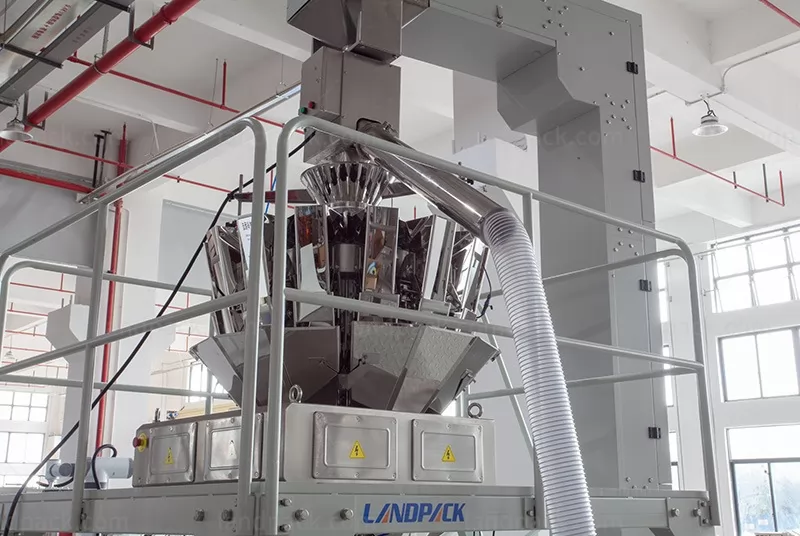

* Z-Type Conveyor – Lifts the product smoothly and steadily to the next stage.

* Falling Metal Detection Machine – Ensures product safety by detecting and rejecting any metal impurities.

* 14-Head Electronic Weighing – Provides fast and highly accurate weighing of granules for consistent packaging.

* Bag Feeding – Automatically places empty pouches into the machine, ready for filling.

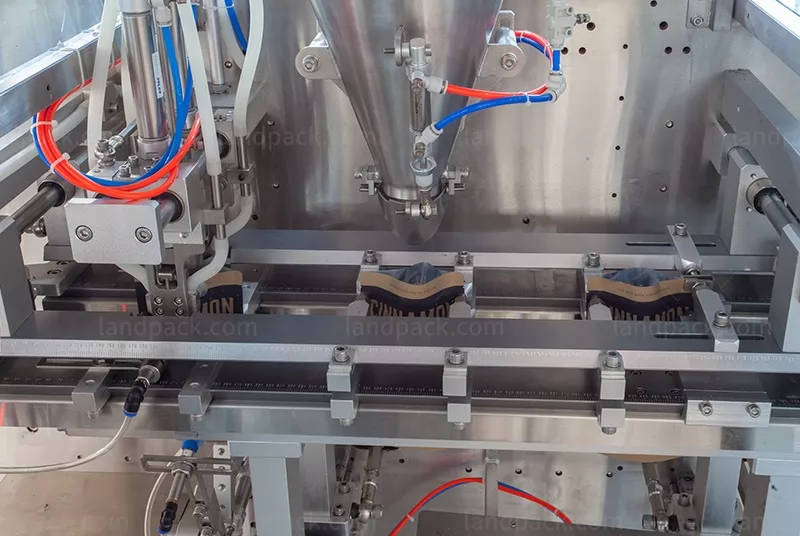

* Zipper & Bag Opening – Opens the pouch precisely, even with zipper bags, for easy and reliable filling.

* Filling – Products are filled into the bag with exact weight control, ensuring no waste.

* Sealing – Heat sealing closes the pouch tightly, keeping the contents fresh and secure.

* Output – The finished bags are neatly delivered, ready for boxing, storage, or sale.