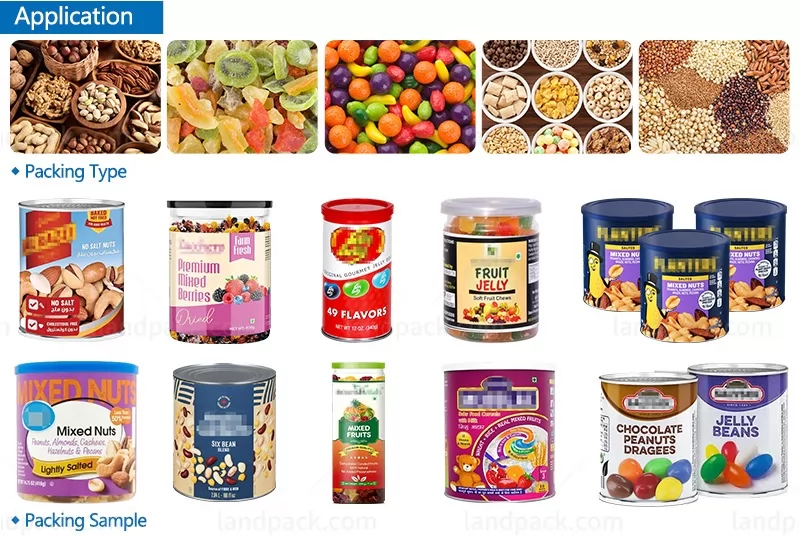

Application:

This nut filling machine is ideal for automatic dosing, can filling, seaming, and labeling of various nut products, including mixed nuts, roasted nuts, cashews, almonds, pistachios, walnuts, macadamias, and other snack granules such as seeds and coated peanuts. It is widely used in food processing plants and commercial nut packaging lines requiring stable output and 50 cans/min high-efficiency production.

Package Type:

This Automatic Mixed Nut Can Tin Filling Seaming Labeling Machine Line supports a wide variety of rigid containers, including tin cans, metal cans, paper/composite cans, plastic PET/PP cans, and other round wide-mouth canisters. It ensures stable filling, secure seaming, and precise labeling across all compatible can types, making it suitable for diverse nut, dried fruit, and snack packaging applications.

Suitable Products:

This Automatic Mixed Nut Can Tin Filling Seaming Labeling Machine Line is engineered for a wide range of granular, small-piece, and mixed food products, ensuring precise filling, stable performance, and consistent packaging quality across diverse material types.

- Nut Category: Snack foods, confectionery items, grains & cereals, various nuts, and dried fruits.

- Dried Fruit Category: Raisins, dried blueberries, cranberries, prunes, and similar dehydrated fruits.

- Other Mix Category: Trail mix, mixed beans, pet food, candies, and other assorted granular or small-piece products.

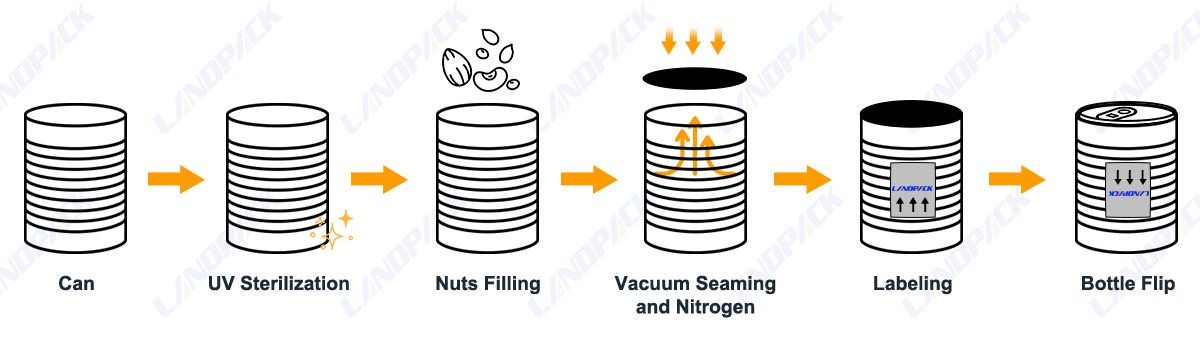

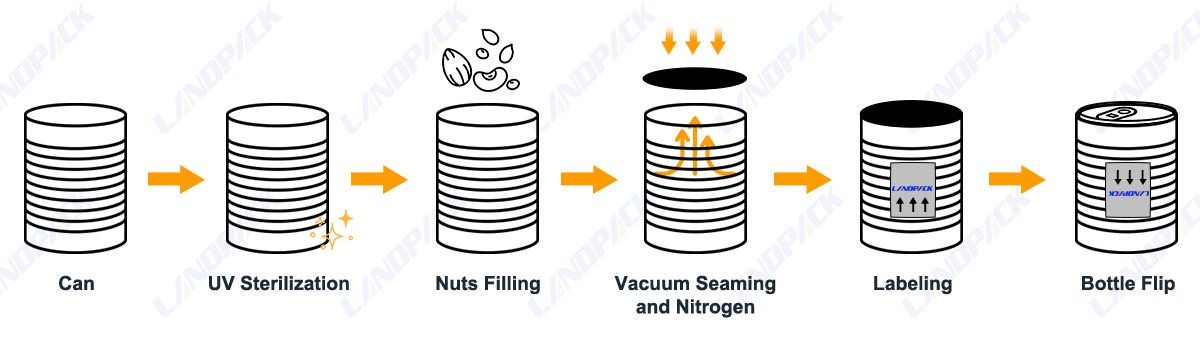

Workflow:

1. Can Feeding: Empty cans enter the production line, ready for processing.

2. UV Sterilization: Cans are sterilized by UV light to create an unhygienic and safe packaging environment.

3. Nuts Filling: Mixed nuts are accurately filled into the cans according to the preset weight.

4. Vacuum Seaming and Nitrogen: The cans are vacuum sealed and then flushed with nitrogen in order to increase shelf life and ensure that the nuts remain fresh and crisp.

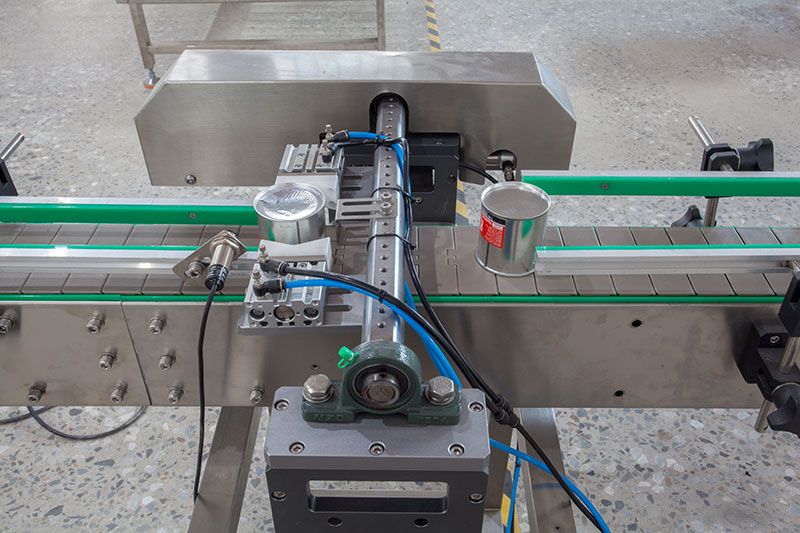

5. Labeling: The automatic labeling system applies brand labels and product information onto the can surface.

6. Bottle Flip: Finished cans are flipped automatically for easier stacking, packing, or downstream conveying.