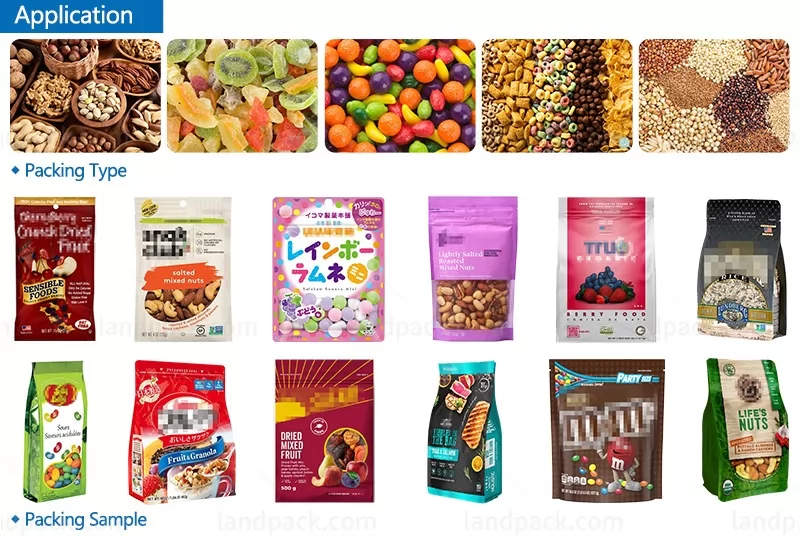

Application:

Mini stand-up pouches that are automatic and a packaging machine designed for mixed nuts snacks. It is precise in mixing, metering and sealing. Perfect for packing mix nuts, cashew, snack, trail mix dried fruits, as well as snack mixes in bags that can be opened up.

Package Type:

This machine is compatible with various premade pouch styles, offering flexibility for different product needs. Suitable bag types include stand-up pouches (doypacks), flat pouches, zipper resealable bags, gusseted bags, and M-shaped bottom bags.

Suitable Products:

This single-station premade pouch packaging machine is designed to handle a wide range of granular, mixed, and free-flowing products with stable feeding and precise pouch filling.

- Nuts, Dried Fruits & Snack Mixes: Almonds, cashews, peanuts, walnuts, raisins, cranberries, mixed dried fruits, trail mix blends.

- Confectionery, Snacks & Bakery Items: Candies, gummies, coated chocolates, crackers, popcorn, extruded snacks, small cookies, and mini biscuits.

- Grains, Cereals & Daily Use Granular Products: Rice, beans, lentils, breakfast cereals, granola, pet food pellets, horticultural granules, desiccant beads, and small hardware items like screws or nuts.

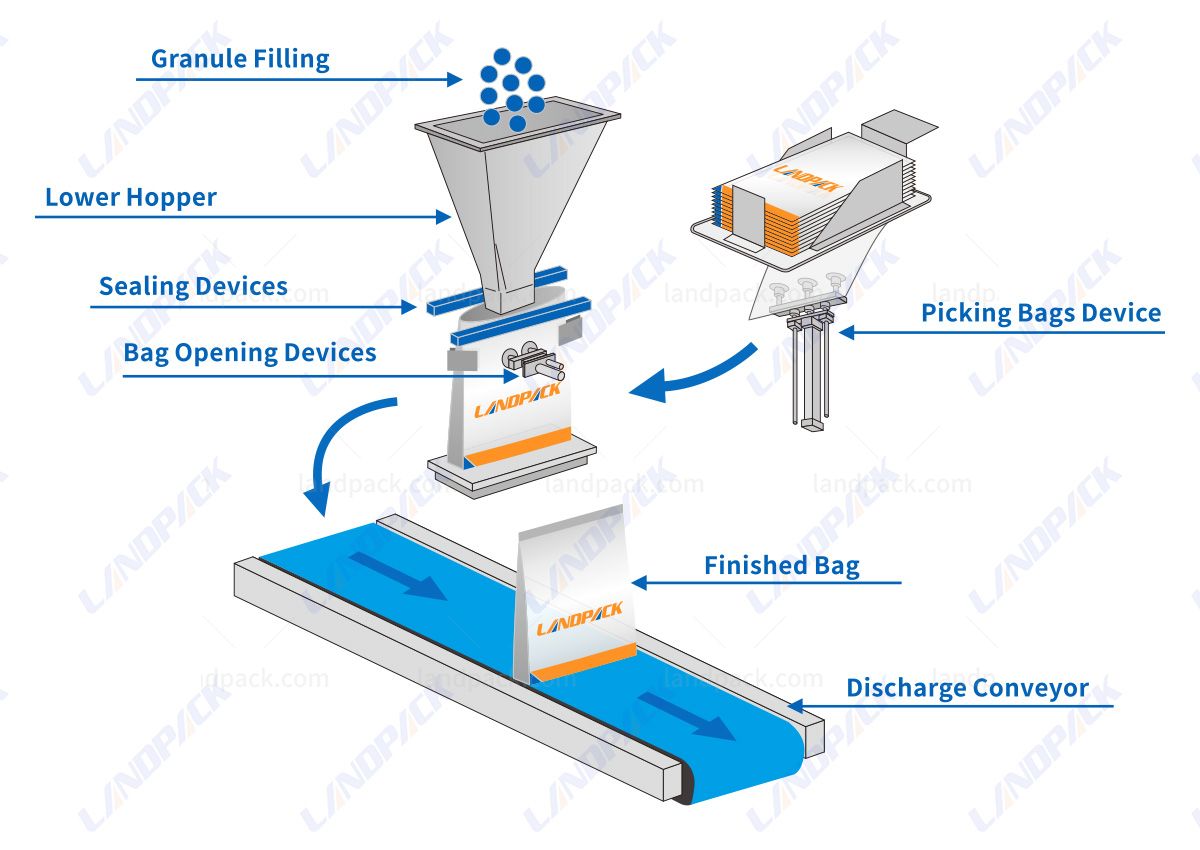

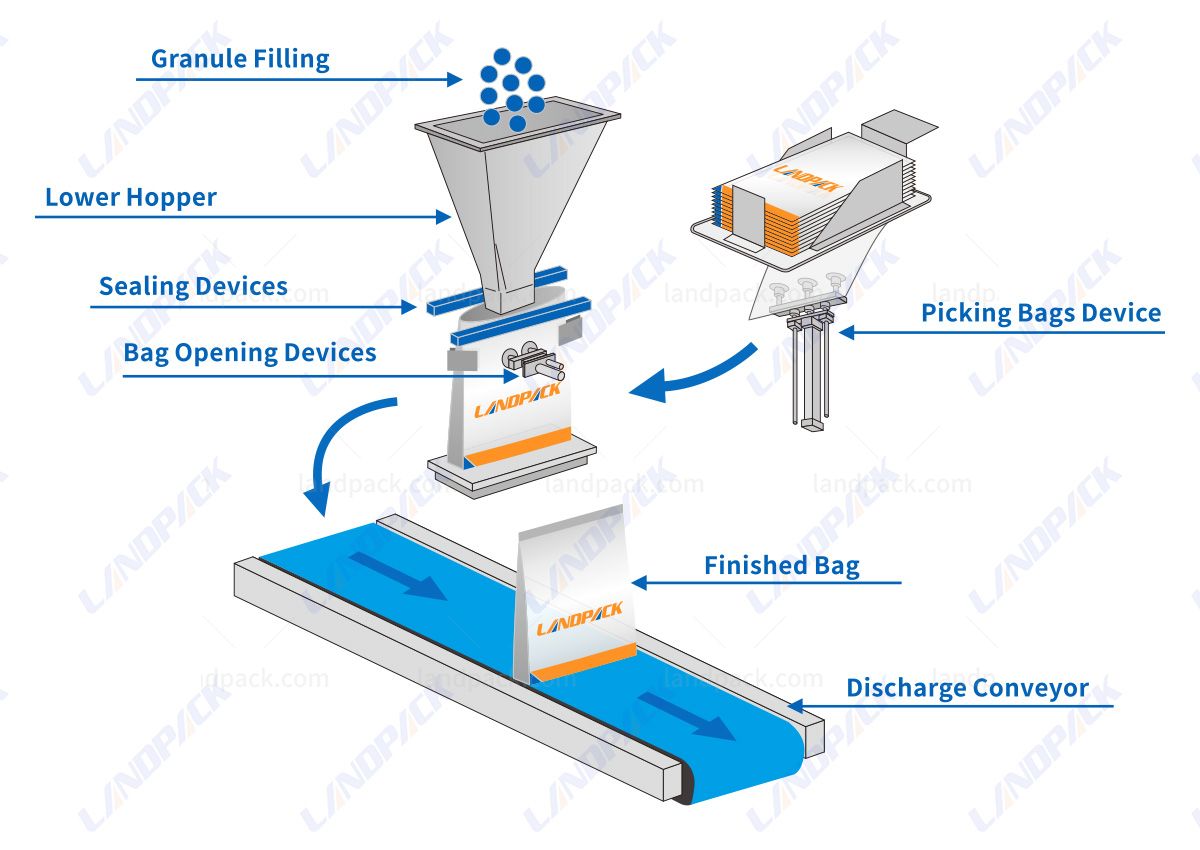

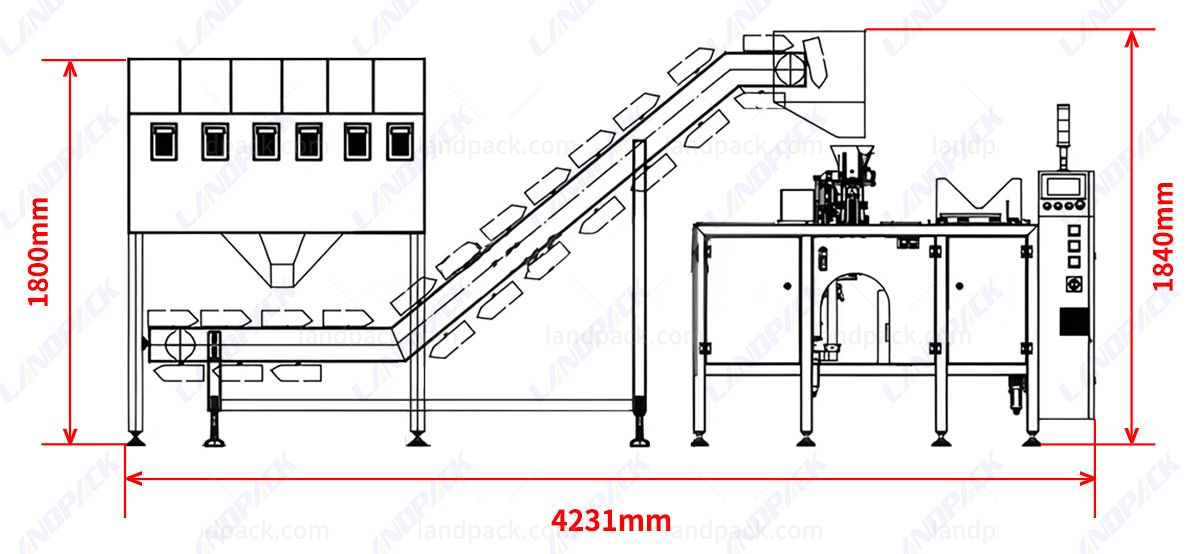

Workflow:

1. Measure and Mix - Different granular components such as nuts and seeds, are precisely measured and mixed evenly.

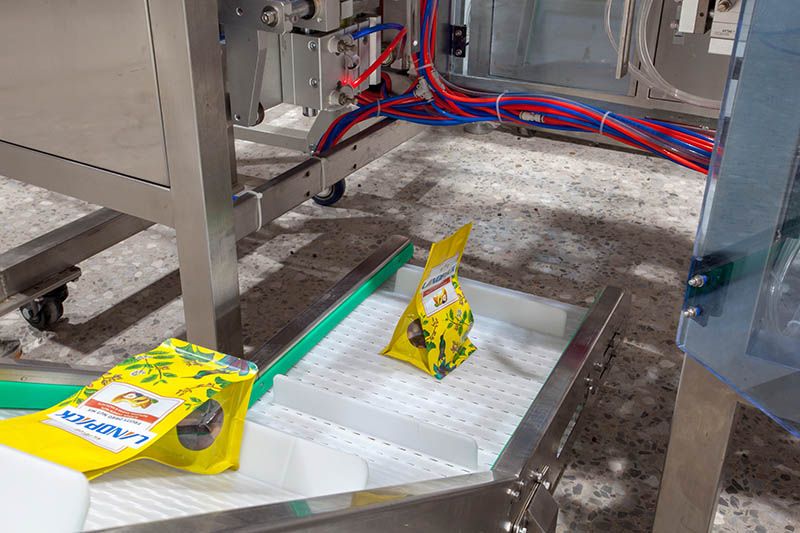

2. Chain Conveyor Filler - The mixed materials are transported smoothly through the chain conveyor until the filling station.

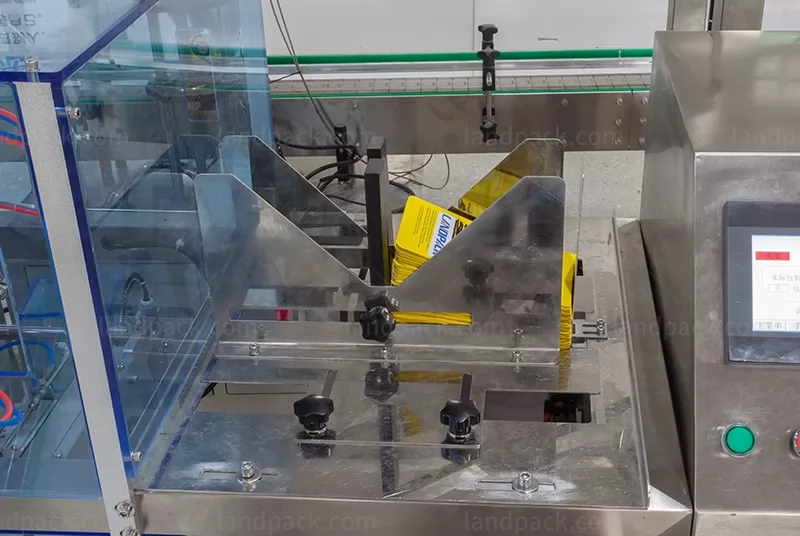

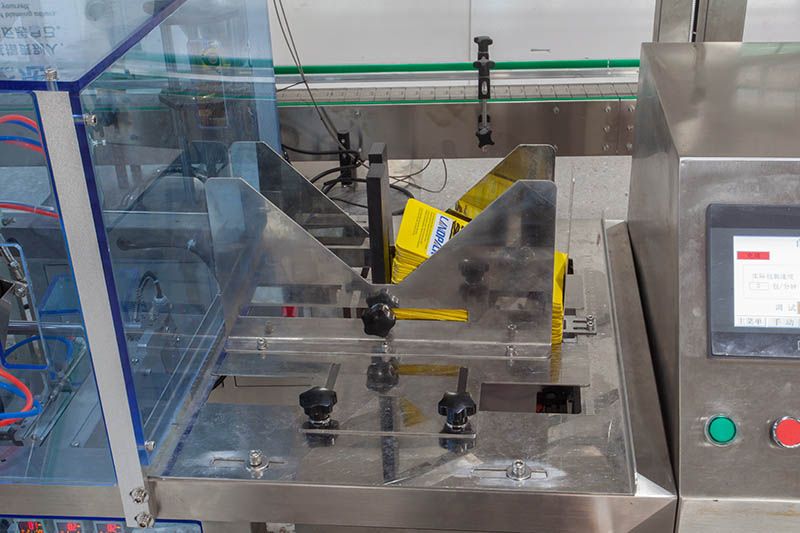

3. Bag Storage - Bags made of pre-made materials are carefully stacked and placed inside the magazine bag.

4. Bag Feeding - This system automates chooses and positions each pouch to be filled.

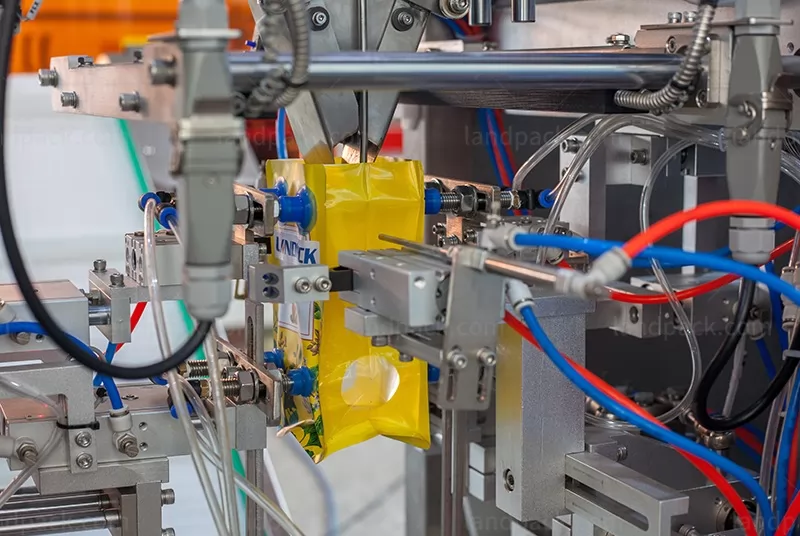

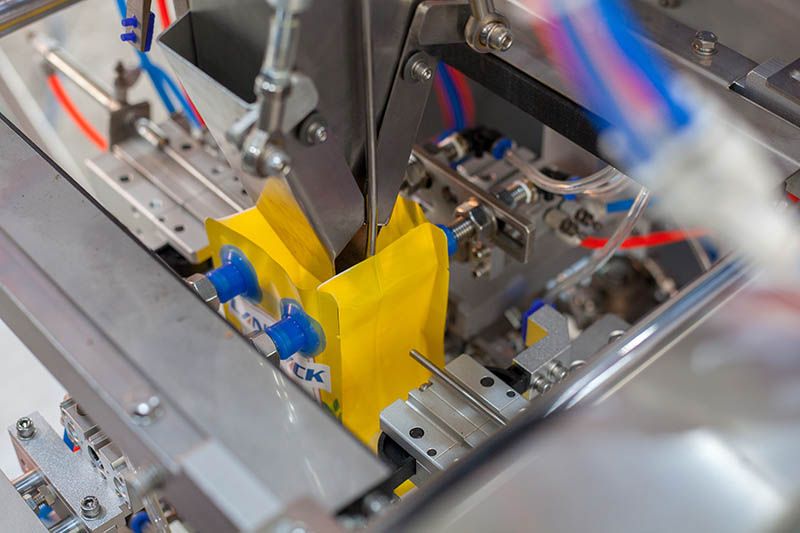

5. Bag opening - Vacuum suction opens up the mouth of the bag precisely.

6. Filling and Nitrogen Injection - Granular substances are dispensed into the pouch that has been opened, and nitrogen is also injected to keep the freshness of the product and prolong shelf life.

7. Sealing - This pouch has been heat-sealed and secure under pressure and temperature control.

8. Output - The sealed bags are transferred to the belt output for simple collection.