Application:

This cosmetic cream filling machine is ideal for handling medium to high-viscosity cream products across cosmetics, personal care, household chemical, and healthcare industries, making it especially suitable for facial creams, moisturizers, conditioners, ointments, cleaning pastes.

Package Type:

This liquid filling line is designed for bottle packaging, making it ideal for creams, lotions, and other semi-viscous cosmetic or pharmaceutical products. It supports a wide range of plastic bottles, glass bottles, PET bottles, and HDPE bottles.

Suitable Products:

The cosmetic cream lotion filling machine—consisting of a bottle unscrambler, single-head gear pump filler, vibrating cap feeder, high-speed capping machine, and inkjet coder—is engineered for smooth, accurate, and hygienic filling of viscous products:

- Personal Care & Cosmetics: facial creams, body lotion, moisturizing cream, cleansing gels.

- Skincare Products: whitening cream, repair cream, anti-aging cream, sunscreen lotion.

- Household & Daily Chemicals: hand cream, hand lotion, multipurpose soft creams.

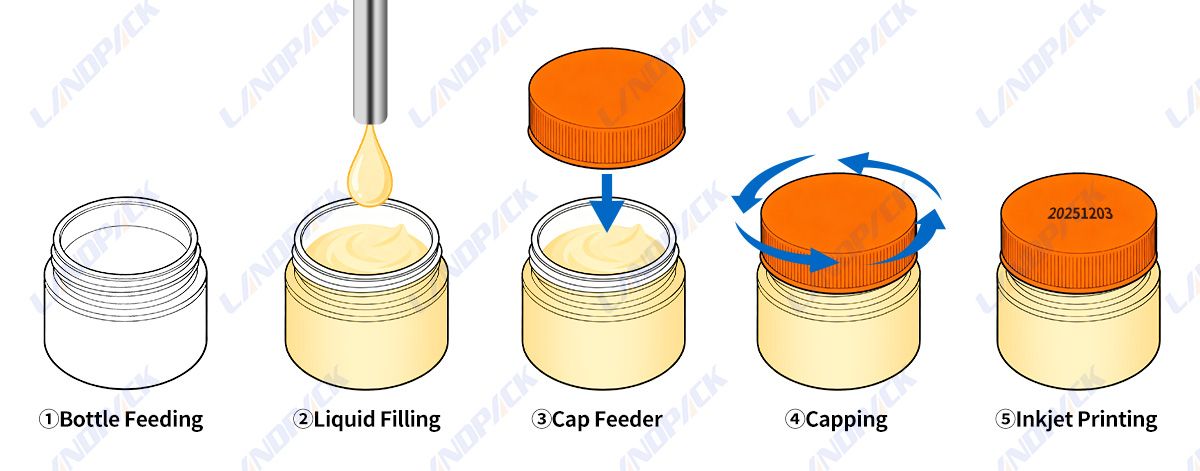

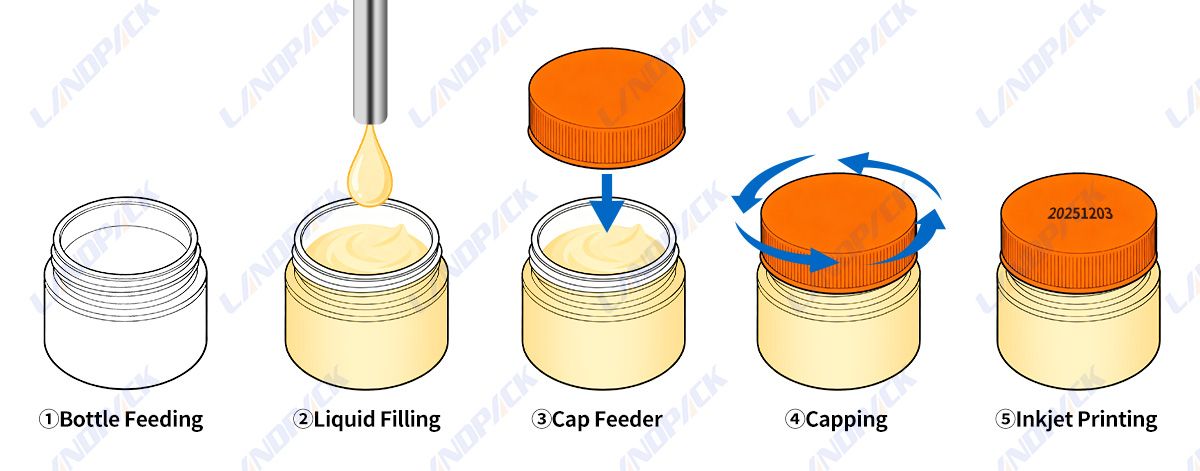

Workflow:

1. Bottle Sorting: The bottle unscrambler automatically arranges and feeds empty bottles onto the conveyor in a stable and continuous order.

2. Cream Filling: The single-head gear pump fills an accurate volume of cream into each bottle.

3. Cap Feeding: The vibration bowl arranges caps in the correct orientation and delivers them to the capping station.

4. High-Speed Capping: The capping machine secures caps tightly onto the bottles, ensuring a reliable and uniform seal.

5. Inkjet Coding: The inkjet printer marks each bottle with date codes, batch numbers before final output.