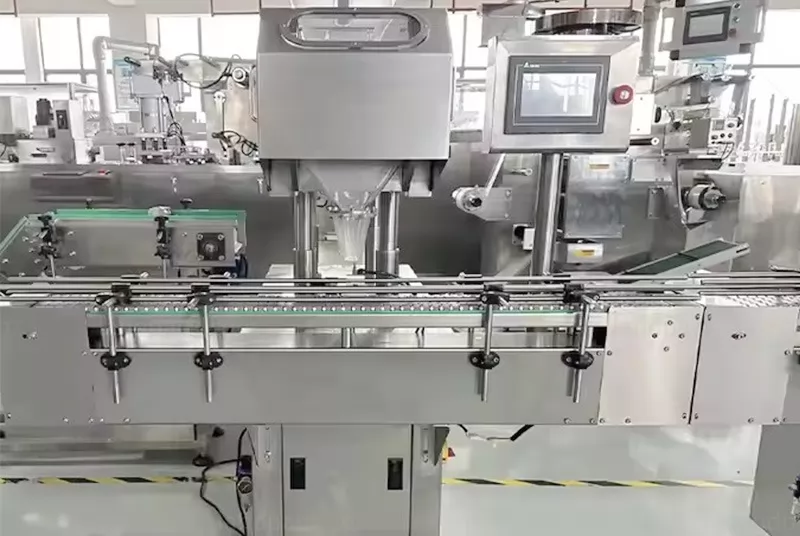

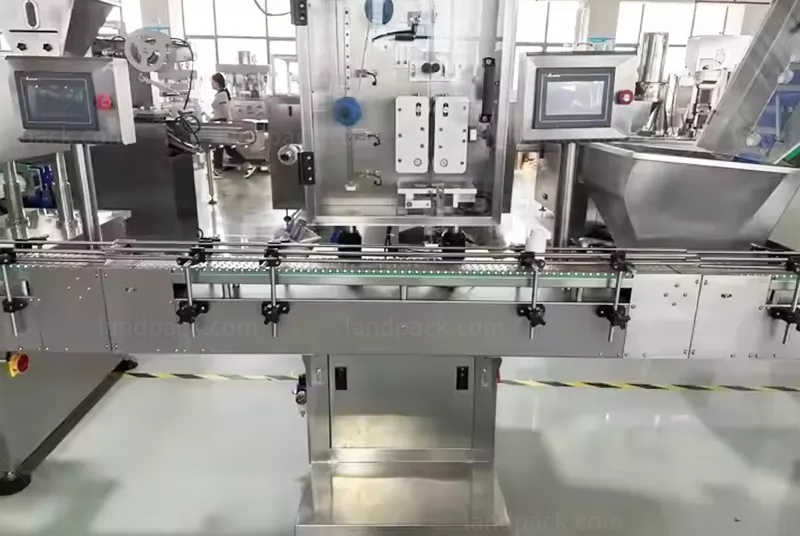

1. The bottle unscrambler, tablet counter, filler, sealer, capper, and labeler are all perfectly coordinated for ever-stable, efficient production.

2. Core units are completely modularized to facilitate versatile arrangement, easy installation, rapid maintenance, and future extension for multi-product streams.

3. Frame: SUS304 construction, and product contact parts: SUS316 construction comply with pharmaceutical hygiene standards.

4. Available in various configurations:

* 8-channel: 20–40 bottles/min

* 16-channel: 50–80 bottles/min

* 32-channel: 100+ bottles/min

5. Stepless frequency control and servo-driven PLC system allow fast and easy switching between product types and bottle sizes.

6. Smart features like "no bottle, no fill" and "no cap, no seal" protect product integrity and reduce material waste.

7. Integrated HMI touch screen enables one-operator control, real-time monitoring, error alerts, and convenient parameter settings.

8. Space-saving footprint with smooth surfaces for easy cleaning—fully aligned with GMP and hygienic production standards.

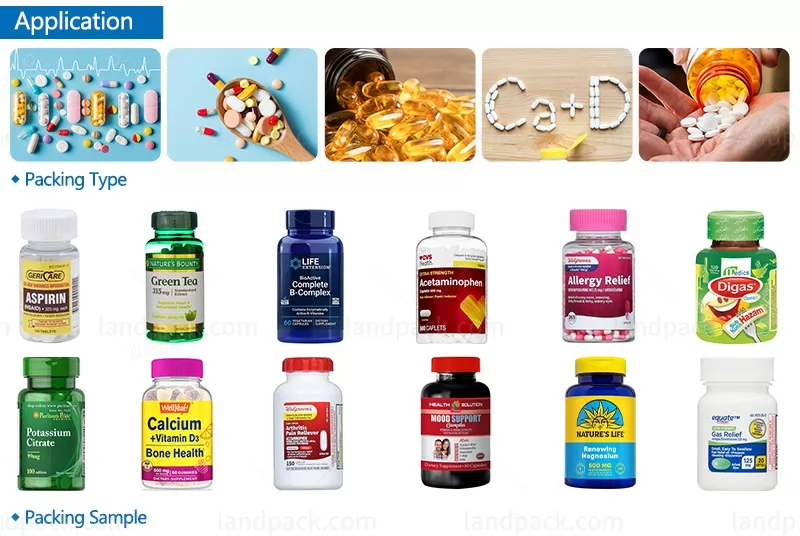

Workflow:

1. Bottle Unscrambler: Organize messy bottles

2. Counting Machine: Counting pills and filling into the bottle

3. Desiccant Inserter: Stuff the desiccant into the bottle

4. Capping Machine: Tighten the cap with an anti-lock to prevent excessive damage

5. Alu-foil Sealing Machine: Seal the bottle lip with aluminum foil

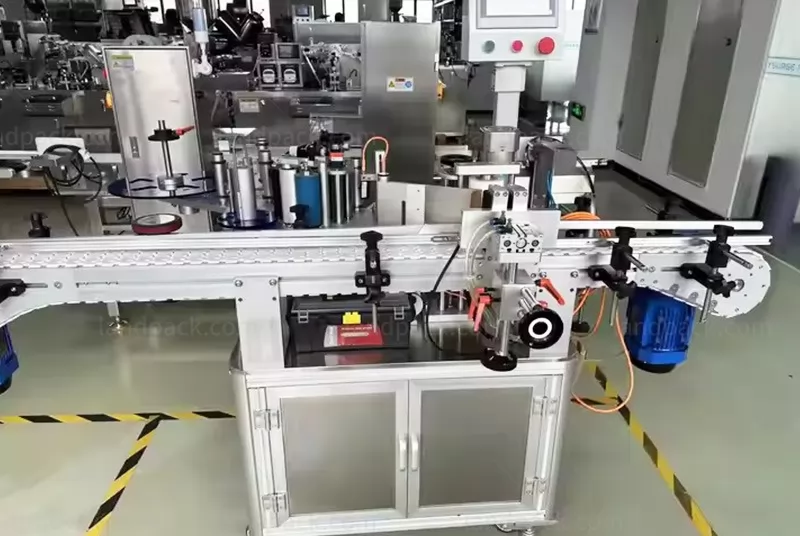

6. Labeling Machine: Stick a label on the body of the bottle automatically

7. Bottle Unscrambler: Organize messy bottles

8. Counting Machine: Counting pills and filling into the bottle

9. Desiccant Inserter: Stuff the desiccant into the bottle

10. Capping Machine: Tighten the cap with an anti-lock to prevent excessive damage

11. Alu-foil Sealing Machine: Seal the bottle lip with aluminum foil

12. Labeling Machine: Stick a label on the body of the bottle automatically