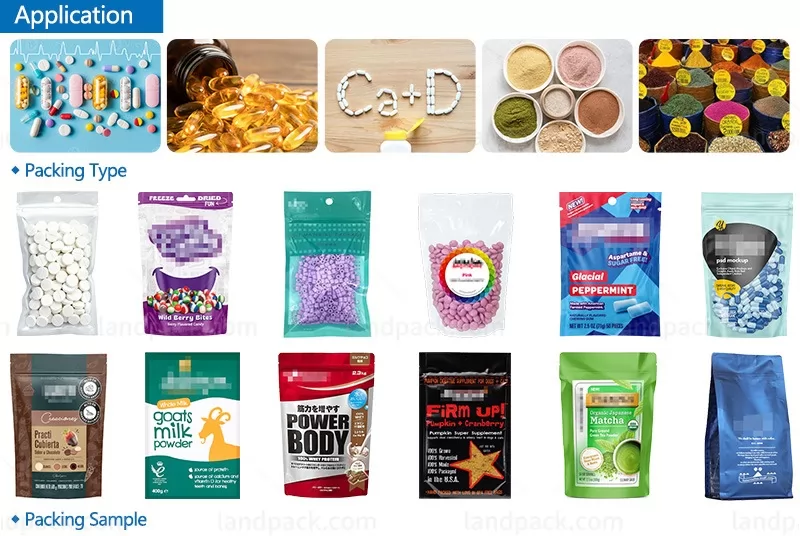

Application:

Ideal for pharmaceutical powders, protein supplements, nutraceutical capsules, effervescent tablets, small granules, and pre-measured scoops, this line delivers consistent portioning with minimal product loss.

Package Type:

This horizontal premade-pouch line is compatible with multiple high-demand pouch formats such as premade pouches, m shape pouches, stand-up pouches, flat pouches, zipper bags, and reinforced laminated pouches used in pharmaceutical, nutraceutical, and food industries. It supports mixed filling of powders, capsules, tablets, and scoops in one pouch.

Suitable Products:

Designed for applications that require precise powder dosing and accurate capsule or tablet counting, this packaging line supports a wide range of products across pharmaceutical, nutraceutical, food, and non-food industries.

- Powdered Materials: Protein powders, medical nutrition powders, instant drink mixes, milk powder, vitamin blends, fine chemical powders, and specialty formulations.

- Capsules & Tablets: Softgel capsules, hard capsules, compressed tablets, effervescent pieces, nutritional pills, and small coated supplements.

- Combination Packs: Powder + capsule mixes, powder + scoop kits, multivitamin pouch packs, sample packs for health products, and customized supplement combos requiring dual filling.

Workflow:

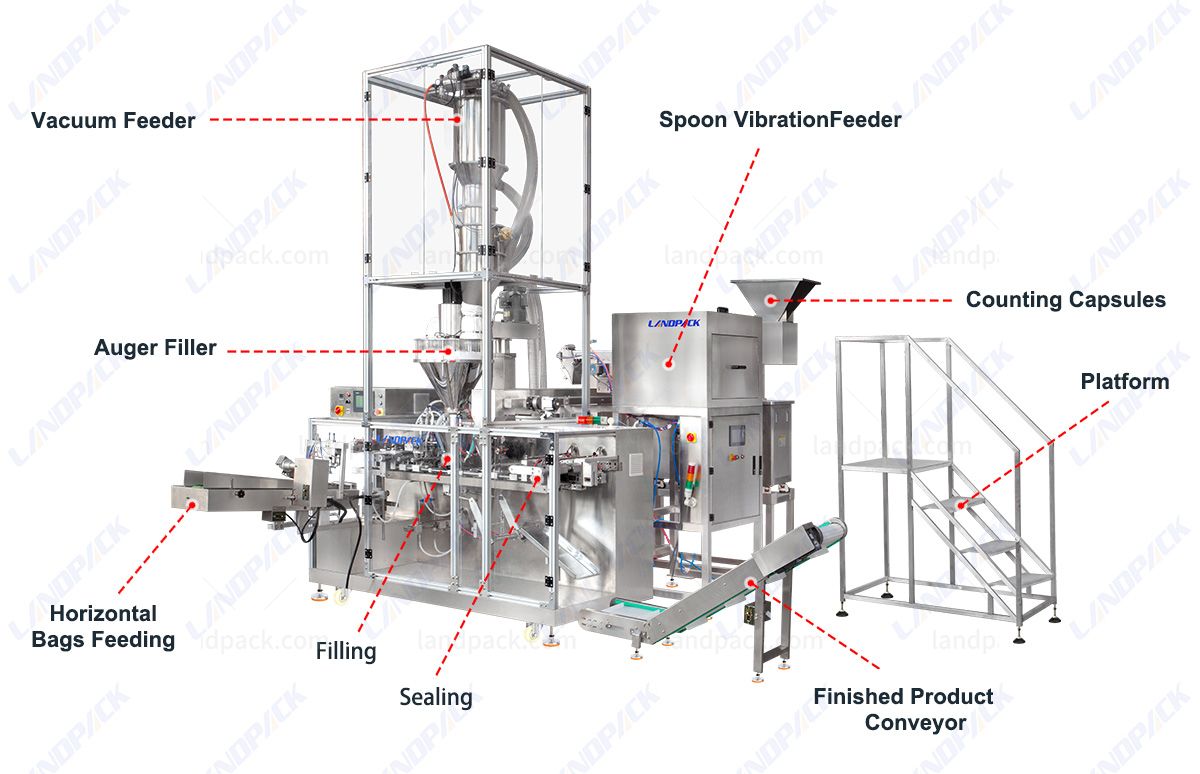

1. Automatic Bag Taking - Premade pouches are automatically picked and positioned onto the working stations, ensuring stable, continuous operation without manual intervention.

2. Inkjet Printing - A high-resolution inkjet printer applies production dates, batch codes, or other necessary markings onto each pouch before filling.

3. Zipper Opening & Bag Opening - Mechanical devices open the zipper (if applicable) and expand the pouch mouth securely, preparing the bag for smooth filling.

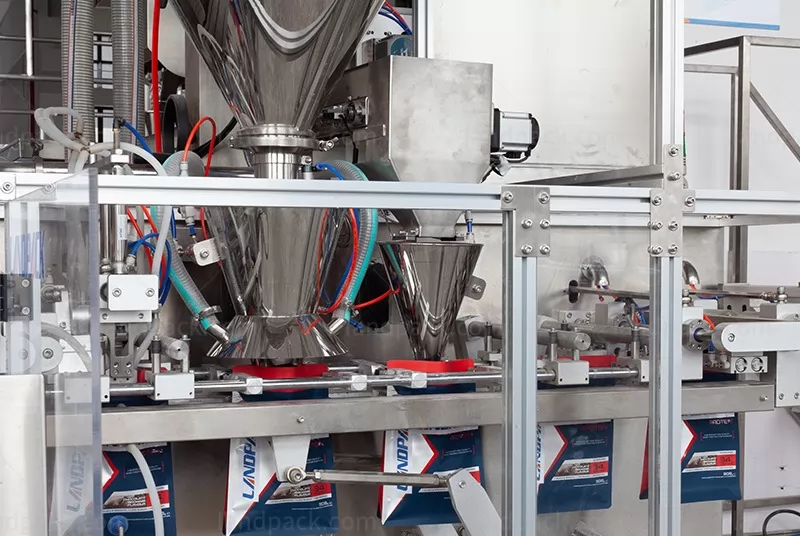

4. Powder Filling & Dust Collection - The servo-driven auger doses powder with high accuracy while the integrated dust collection system removes airborne particles.

5. Tablet / Capsule Counting & Filling - Electronic counting system for tablets and capsules

6. Powder Vacuum Feeder - Powder is automatically transferred from bulk storage to the auger hopper using a vacuum feeding system.

7. Counting Capsules - High-speed photoelectric sensors accurately count each capsule.

8. Spoon Vibration Feeder - For spoon kits or accessories, vibrating channels guide and count each spoon before filling.

9. Hot Sealing - After filling, the pouch is sealed using a temperature-controlled sealing system.

10. Euro Hole Punching - If required, the machine punches a euro-slot at the top of the pouch, making the product ready for retail hanging display.