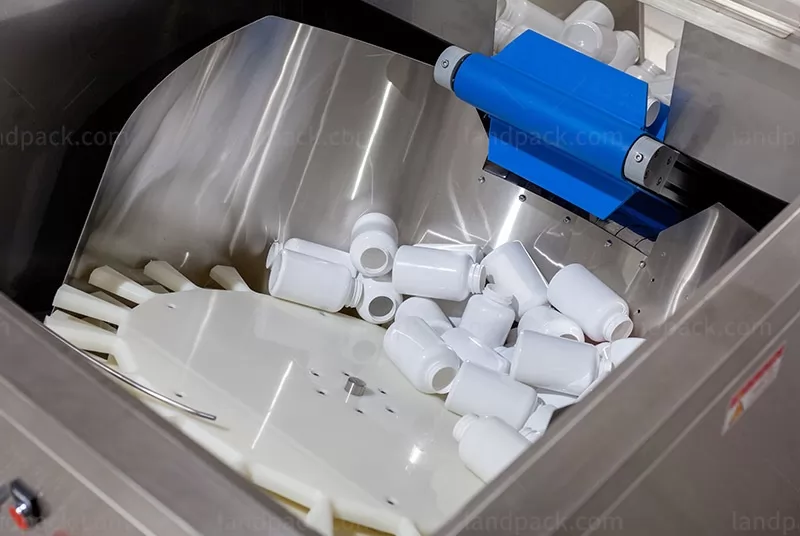

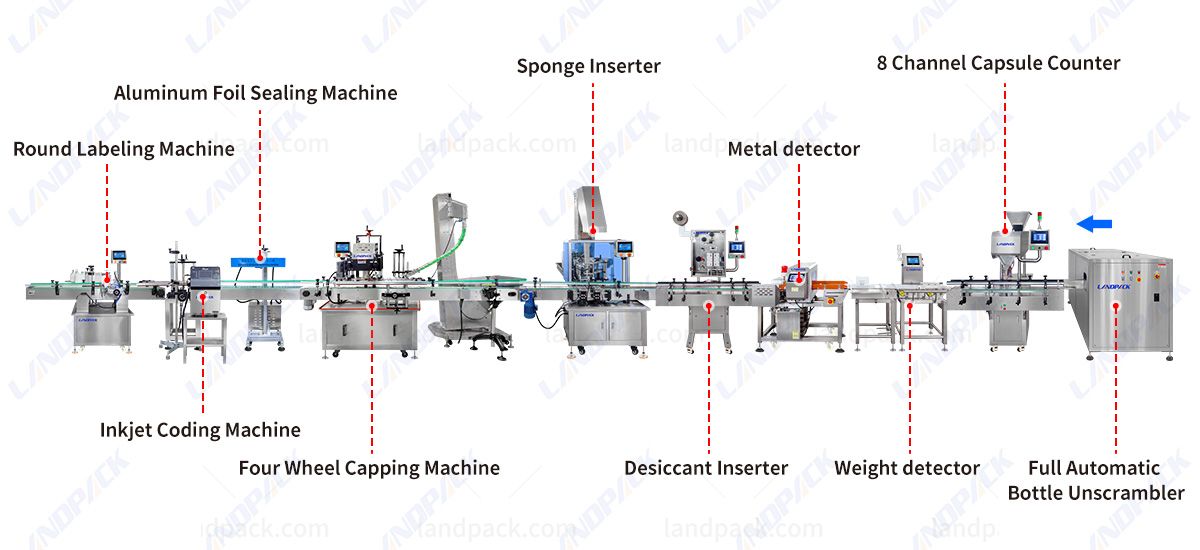

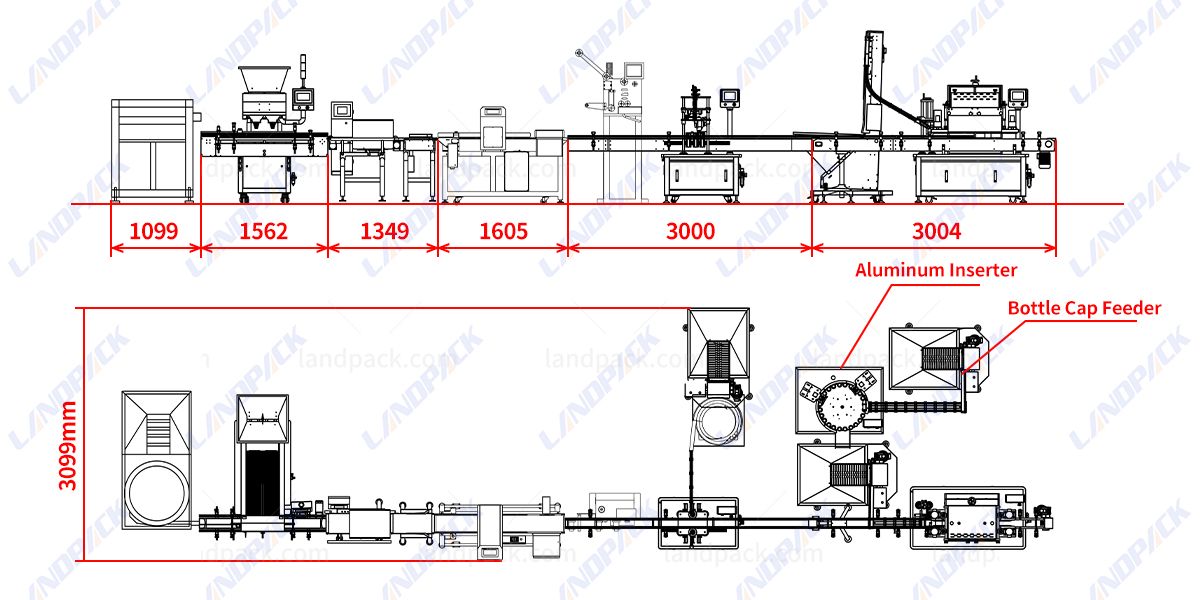

| Automatic Bottle Unscrambler |

| Bottle size range | 15-300 ml |

| Power | 0.50 KW |

| Air pressure/supply | 0.5 MPa / 0.2 m³/h |

| Dimensions (L×W×H) | 1006×1506×1200 mm |

| Weight | 260 kg |

| Bottle diameter range | 30-85 mm |

| Output | up to 260 bottles/min |

| Power consumption | 3.4 KW |

| Compressed air | 3.5 cfm (≈ 100 L/min) |

| 8-Channel Capsule Counting Machine |

| Output / Bottles per min | up to 50 bottles/min |

| Counting Accuracy / Precision | > 99.80 % |

| Power / Voltage | 0.6 kW, 380 / 220 V, 50 Hz Richpacking |

| Net Weight | 360 kg |

| Capacity | 10–30 bottles/min |

| Counting range | 1–999 grains |

| Tablet / Capsule size | Tablet: 3–22 mm, Capsule: 00–5 |

| Air pressure & consumption | 0.4–0.6 MPa, ~120 L/min |

| Overall size | 1800*1300*1600 mm |

| Desiccant Bag Dispenser |

| Insertion Speed | 60-150 bottles/min (depending on model & sachet size) |

| Sachet Type | Single strip or continuous roll, paper/film sachets |

| Sachet Size Range | Length 20-60 mm; Width 15-30 mm (customizable) |

| Bottle Size Range | Diameter 30-120 mm; Height up to 250 mm |

| Cutting & Feeding | Automatic sachet cutting, positioning, and inserting |

| Insertion Accuracy | ≥ 99.8% |

| Control System | PLC with touch screen operation |

| Power Supply | AC 220 V, 50/60 Hz, 1.0 kW |

| Air Requirement | 0.4-0.6 MPa, ~100 L/min |

| Machine Weight | 300-400 kg |

| Metal Detector |

| Metal detection tunnel size | 200 mm (W) × 150 mm (H) |

| Continuous weighing range | 6-600 g |

| Weighing accuracy | ±0.3 g |

| Max throughput | 120 containers/min |

| Detection sensitivity (no product) | Fe ≥ 0.8 mm, Non-Fe ≥ 1.0 mm, SS ≥ 1.2 mm |

| Checkweigher range | 20-5,000 g |

| Accuracy | ±0.02 g |

| Max product width/height | up to 290 mm width, 5-280 mm height |

| Weight detector |

| Weighing Range | 1 g - 6,000 g |

| Accuracy | ±0.2 - ±0.5 g (depending on product & speed) |

| Max Throughput | 100 - 400 pcs/min |

| Conveyor Speed | 2 - 60 m/min, adjustable |

| Conveyor Width | 50 - 600 mm (customizable) |

| Resolution | 0.01 g / 0.1 g / 0.5 g (optional) |

| Reject Mechanism | Air blast, pusher, drop gate, or swing arm |

| Power Supply | AC 220 V, 50/60 Hz |

| Air Requirement | 0.5 - 0.7 MPa (for reject device) |

| Machine Dimensions | Approx 1200 × 710 × 750 mm |

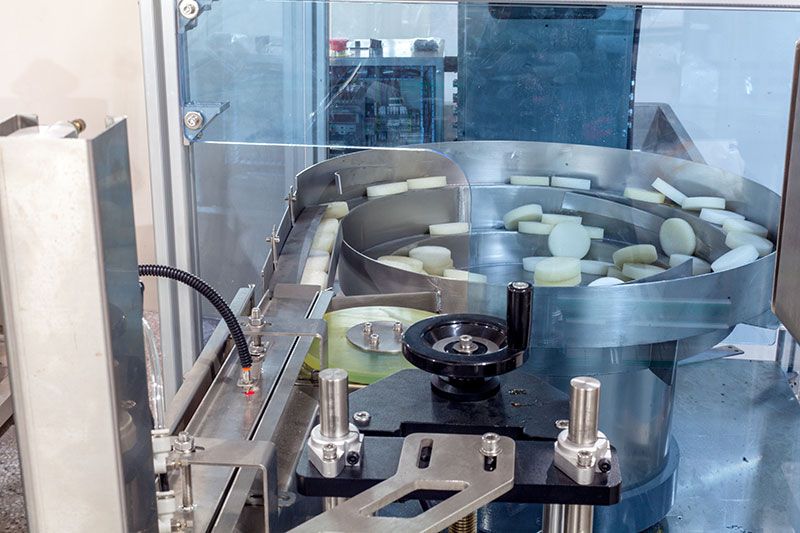

| Sponge dispenser |

| Insertion speed | e.g. 100-200 bottles/min |

| Insertion accuracy | e.g. ±1 mm or better |

| Bottle neck/mouth diameter range | customizable, e.g. 15–50 mm |

| Power & pneumatic | e.g. 220 V / 50 Hz, air 0.4–0.6 MPa |

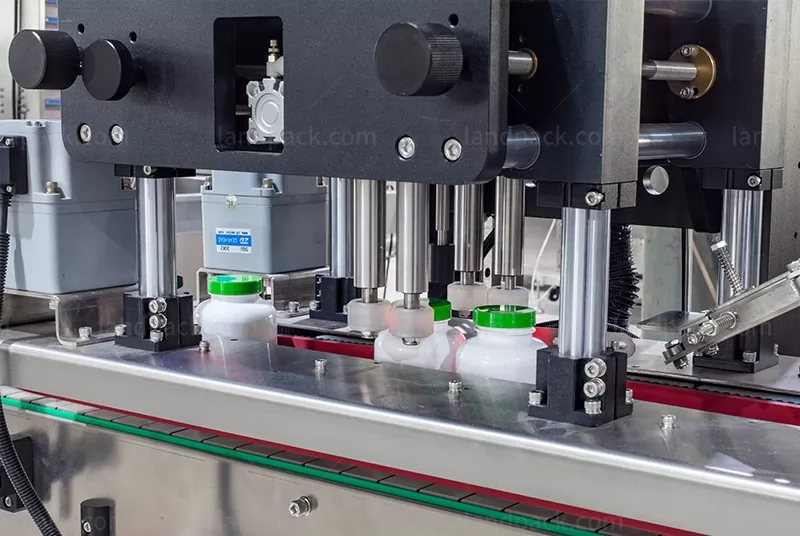

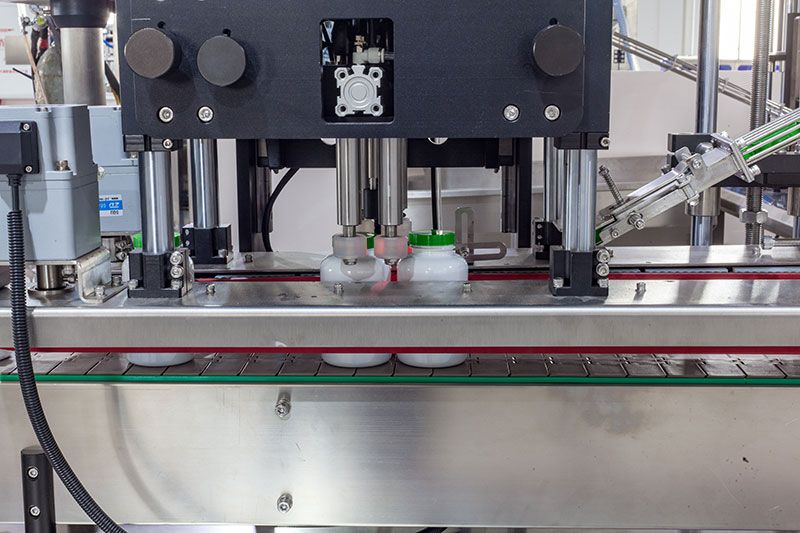

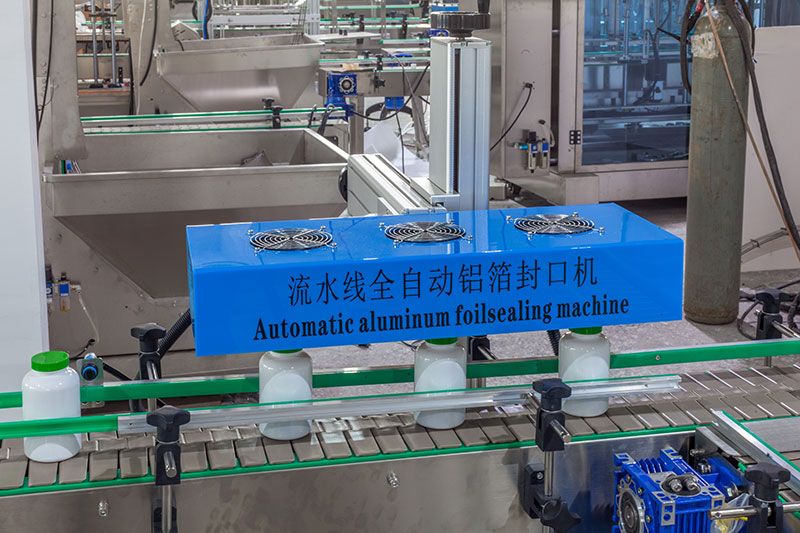

| Aluminum foil sealing machine |

| Model | LD-ZS(Double Heads Aluminum Foil Sealing) | LF-LB-2000(Single Heads Aluminum Foil Sealing) |

| Applicable bottle diameter | Φ10-200mm (Could be customized) | Φ10-200mm (Could be customized) |

| Applicable bottle height | H:40-300mm (Could be customized) | H:40-300mm (Could be customized) |

| Speed | 0-30 bottles/min | 0-10 bottles/min |

| Bottle material | Glass, ceramics, plastics, metals | Glass, ceramics, plastics, metals |

| Voltage | 220V,50HZ | 220V,50HZ |

| Power | 1500W | 1200W |

| Dimension | 1500*800*1750mm | 1200*600*1550mm |

| Bottom Inkjet Coding Machine |

| Printing speed | 1024 seconds(5*7) |

| Power | 220V/50HZ,150VA |

| Printing direction | Positive sequence/reverse order/reverse/reverse |

| Printing distance | The nozzle and the object to be sprayed are kept within 3cm |

| Store information | The system can store 1000 print information |

| Ink consumption | 70 million words per print |

| Machine weight | 48kg |

| Automatic Labeling Machine |

| Model | LFT-LG-100(Low speed labeling) | LFT-GS-100(High speed labeling) |

| Label length | 20mm~300mm | 20mm~300mm |

| Label width/height | 20mm~200mm(can be customized) | 20mm~200mm(can be customized) |

| Bottle width | 30-150mm(can be customized) | 30-150mm(can be customized) |

| Roll Label outer diameter | 300mm | 300mm |

| Roll Label inner diameter | 76mm | 76mm |

| Accuracy | ±1mm | ±1mm |

| Label speed | 40-100pcs/min | 60-120pcs/min |

| Conveyor speed | 5~25m/min | 15~20m/min |

| Suitable label type | Adhesive sticker label(transparent label need customized) | Adhesive sticker label(transparent label need customized) |

| Working air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Voltage | 220V can be customized 4KW | 220V can be customized 4KW |

| Weight | 350KG | 450KG |

| Overall dimension | 3000mm×1450mm×1950mm | 3050mm×1550mm×1950mm |