1. Wide Tube Compatibility – Suitable for both aluminum and plastic tubes, offering versatility for different products.

2. Quick Adjustment – Simple changeover between tube sizes and materials, reducing downtime.

3. High-Speed Operation – Efficient filling and sealing with stable performance for mass production.

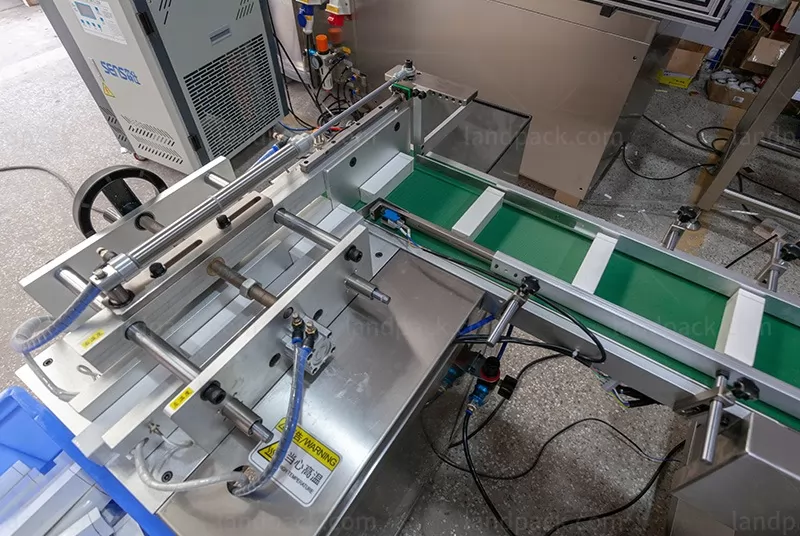

4. Water-Cooled Sealing System – Ensures strong, neat, and visually appealing seals while preventing heat damage.

5. Automatic Weight Checking & Rejection – Detects and removes underweight or overweight tubes, ensuring product consistency.

6. Integrated Cartoning Machine – Automatically packs filled tubes into cartons for efficient secondary packaging.

7. Cellophane Wrapping – Applies an additional transparent wrap, enhancing product appearance and protection.

8. Compact & Hygienic Design – SUS304 stainless steel construction for easy cleaning and compliance with food and cosmetic standards.

Workflow:

1. Automatic tubes feeding

2. Automatic manual folding-automatic put tubes and manual into cardboard mark checking

3. Automatic filling material in the tube

4. Plastic tube sealing/aluminum tube folding

5. Date printing

6. Finished tube

7. Weight detector

8. Tubes feeding into the cartoning machine

9. Manual folding, automatic put tubes and manual into cardboard

10. Automatic cardboard sealing

11. Automatic conveying of finished carton boxes into the BOPP film shrink wrapping machine

12. Finished products