Application:

This pickle filling machine is widely used for automatic can filling and sealing of pickled foods and preserved products, including pickled fruits, vegetables, olives, cucumbers, kimchi, and mixed pickles with both solid granules and brine liquid. It is suitable for food processing factories, pickle manufacturers, and can filling lines requiring accurate filling, hygienic seaming, and efficient coding in metal cans or similar containers.

Package Type:

This pickle filling machine is compatible with various rigid containers commonly used in the food and preserved food industries. The can filling line ensures stable filling, sealing, and coding for different container types and sizes.

Suitable Products:

This machine is designed for products containing both solid pieces and liquid, making it ideal for automatic filling and seaming of mixed or brine-based foods in the food processing industry.

- Food Industry: Fruit pieces, corn, peas, beans

- Preserved Foods: Kimchi, olive fruit, pickled cucumber, pickled chili

- Others: Pet food, mushroom soup, sauce, rice wine

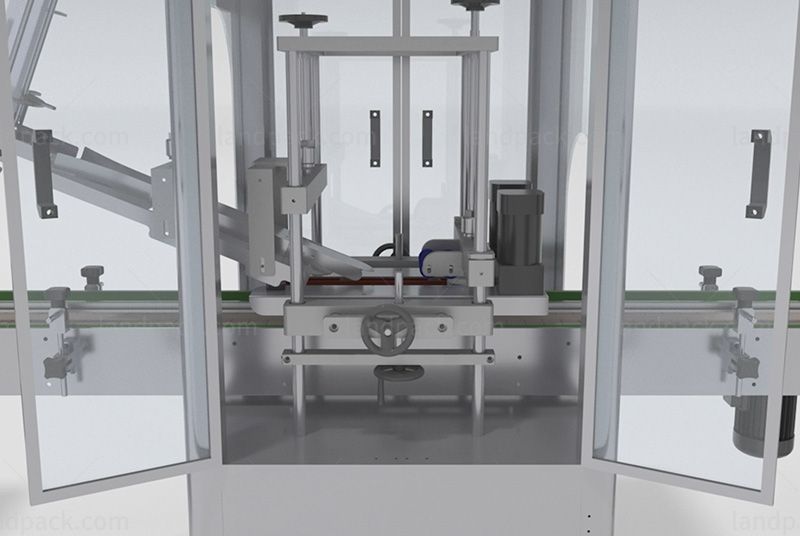

Workflow:

1. Cans Feeding: Empty cans are automatically fed into the can filling line, ensuring smooth and continuous operation.

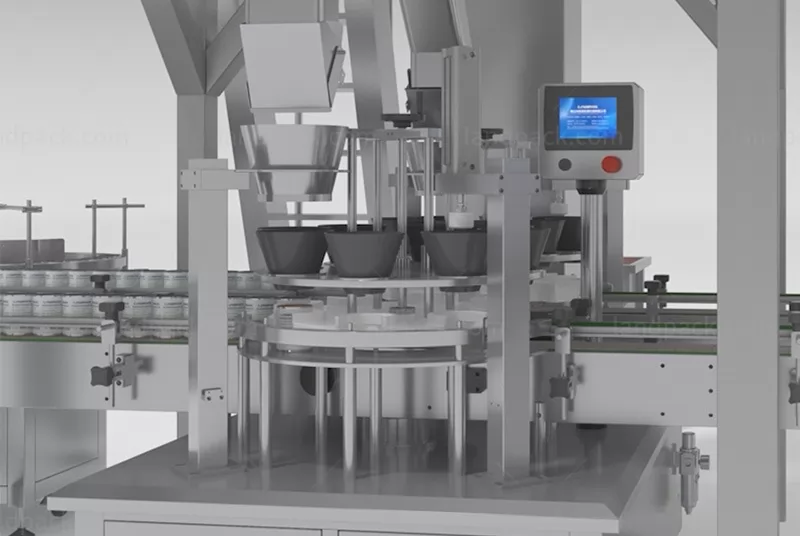

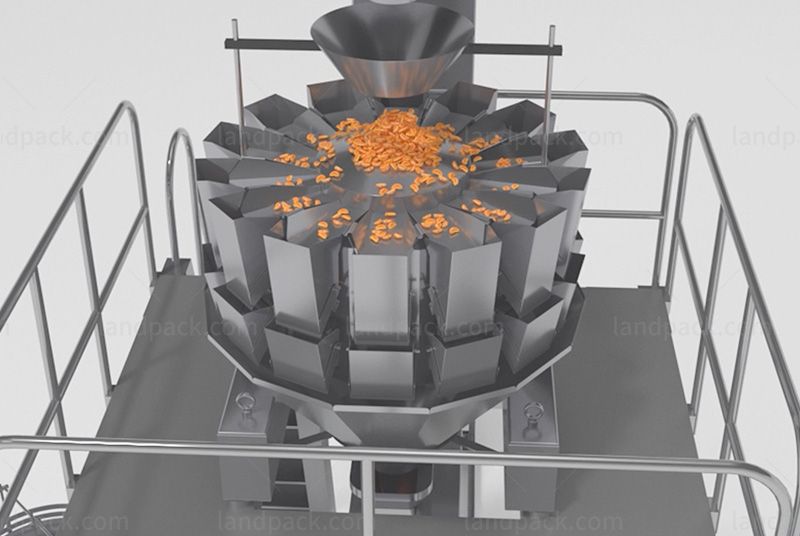

2. Weighing: High-precision weighing system controls the filling weight accurately, improving filling consistency and efficiency.

3. Granule Filling: Solid or granule materials are filled precisely by the pickle filling machine, suitable for pickled fruits and vegetables.

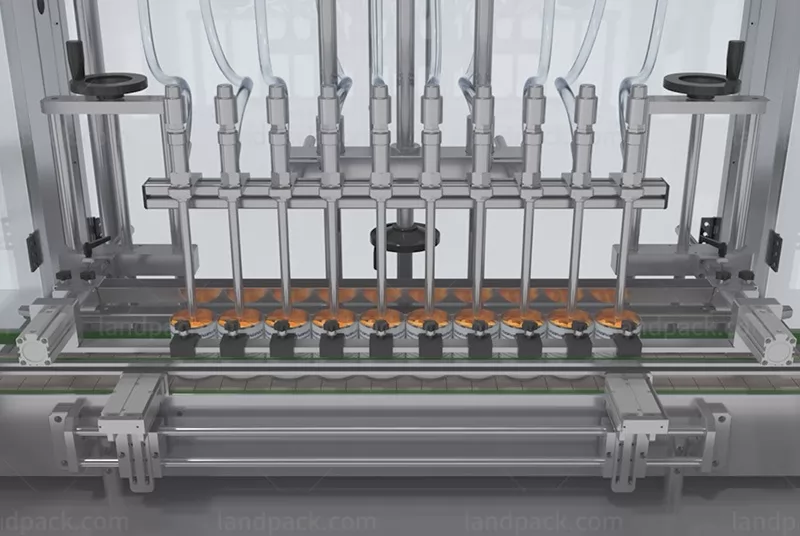

4. Liquid Filling: Brine, sauce, or liquid is added automatically to achieve reliable solid-liquid combination filling.

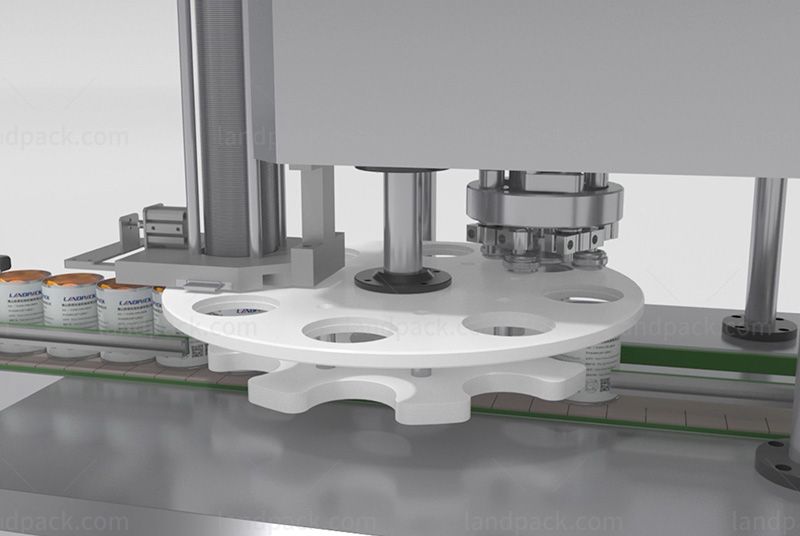

5. Cans Seaming: The pickle packing machine performs tight can seaming to prevent leakage and extend product shelf life.

6. Cap Pressing: Caps are firmly pressed to enhance sealing strength and ensure packaging safety.

7. Laser Printer: Integrated laser coding system prints production date, batch number, or traceability information.

8. Finished Product Output: Finished cans are smoothly discharged from the can filling line, ready for secondary packing or inspection.