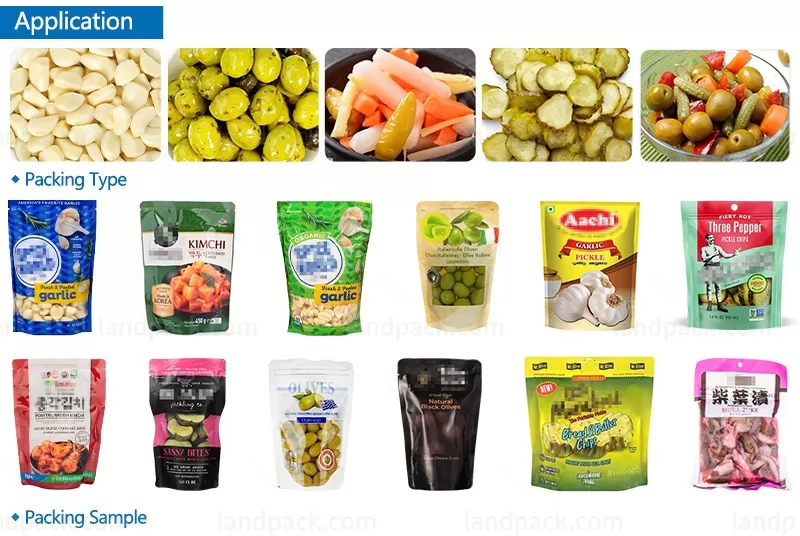

Application:

Perfect for packaging almonds, cashews, pistachios, popcorn, banana chips or mixed snacks — and easily adapted for non-food items like seeds, pet food or hardware granules.

Package Type:

Our horizontal pouch packing machine accepts a wide variety of flexible pouch formats: classic flat pouches, self-standing stand-up or doypack pouches, resealable zipper bags, and robust quad- or flat-bottom pouches.

Suitable Products:

Designed for multi-head weighing, this line handles both irregular moist foods and free-flowing dry materials with stable accuracy and gentle product handling.

- Pickled Products: Kimchi, seasoned pickles, olives, marinated vegetables, preserved radish, and other brined or lightly sauced fermented items.

- Granular Products: Sugar, salt, beans, rice, seeds, pellets, pet-food granules, small chemical granules.

- Nuts & Snack Products: Almonds, cashews, peanuts, pistachios, trail mixes, chips, puffed snacks, dried fruits, and mixed snack blends.

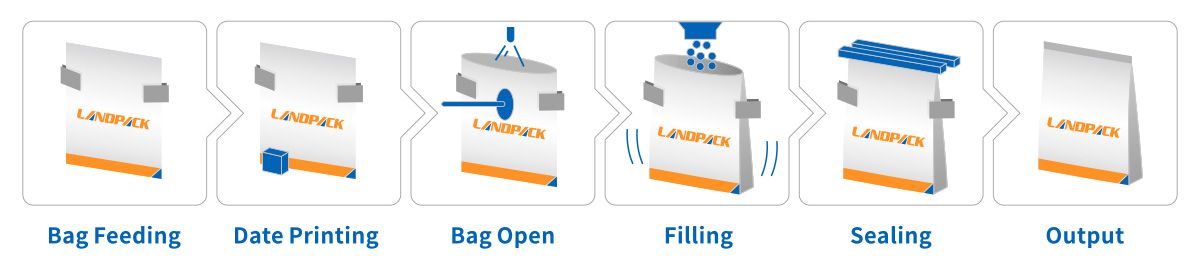

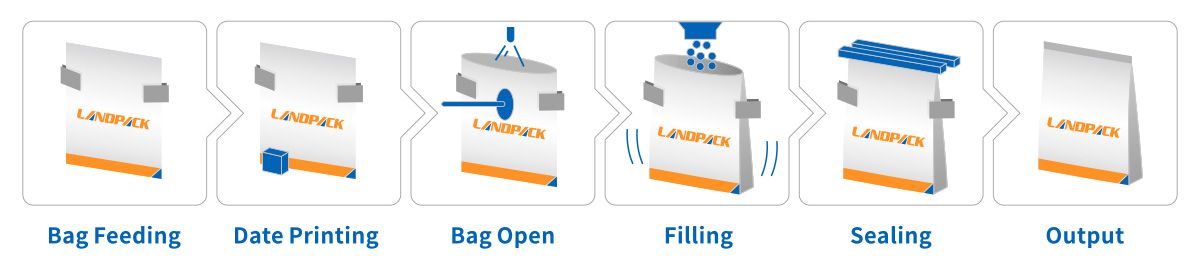

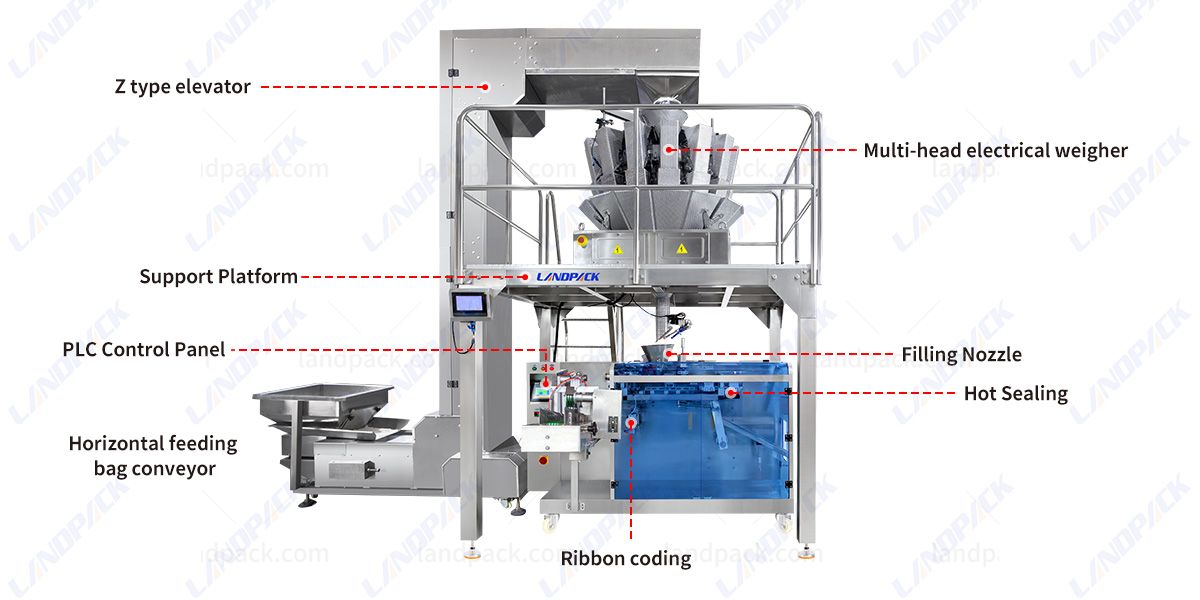

Workflow:

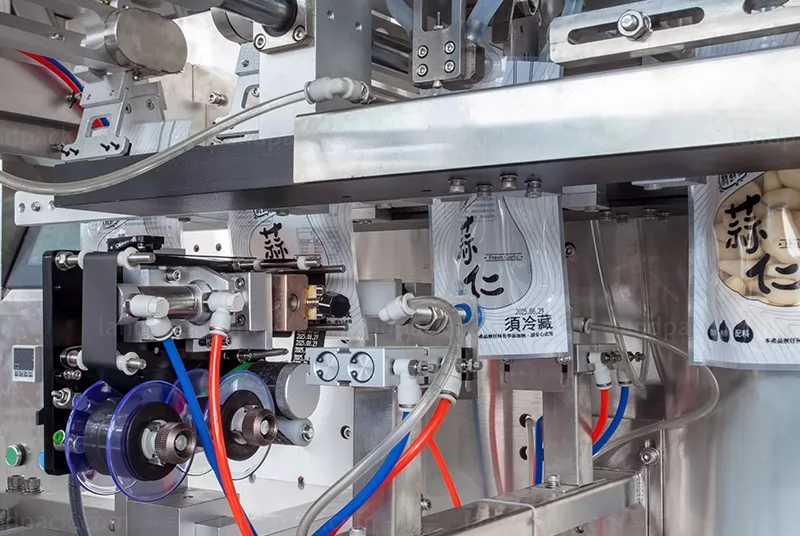

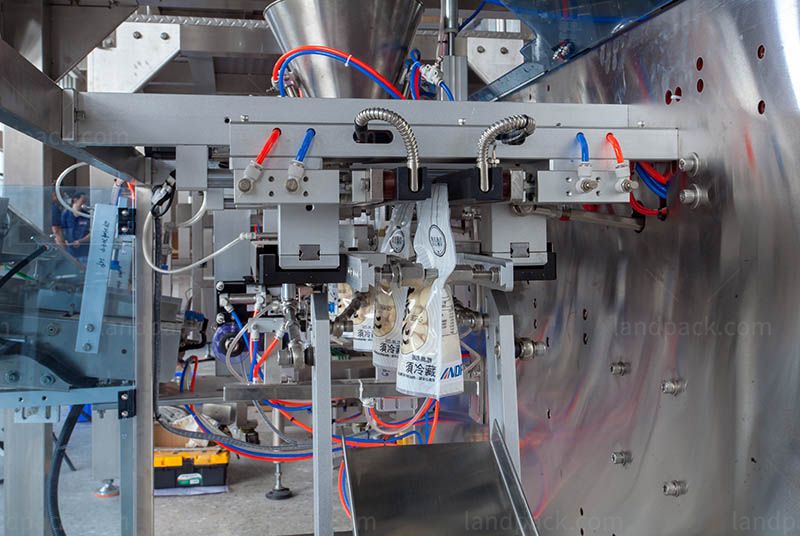

1. Pouch Feeding - Premade pouches are automatically picked and placed onto the horizontal conveyor.

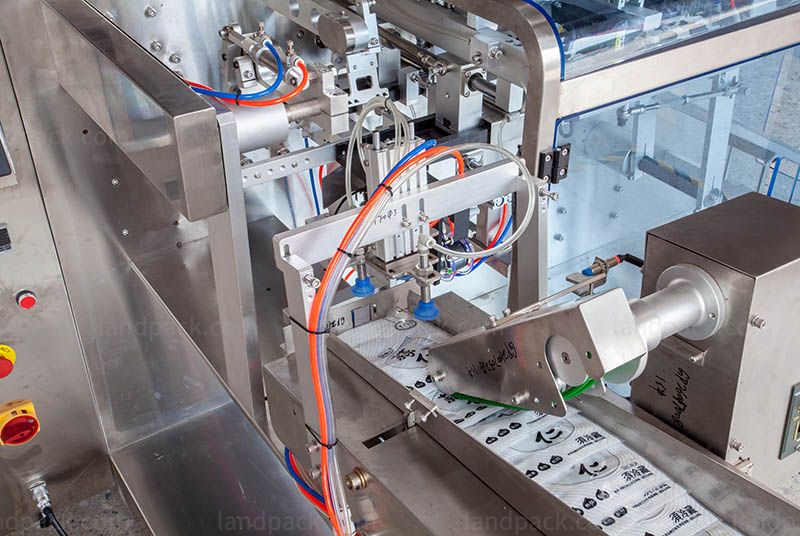

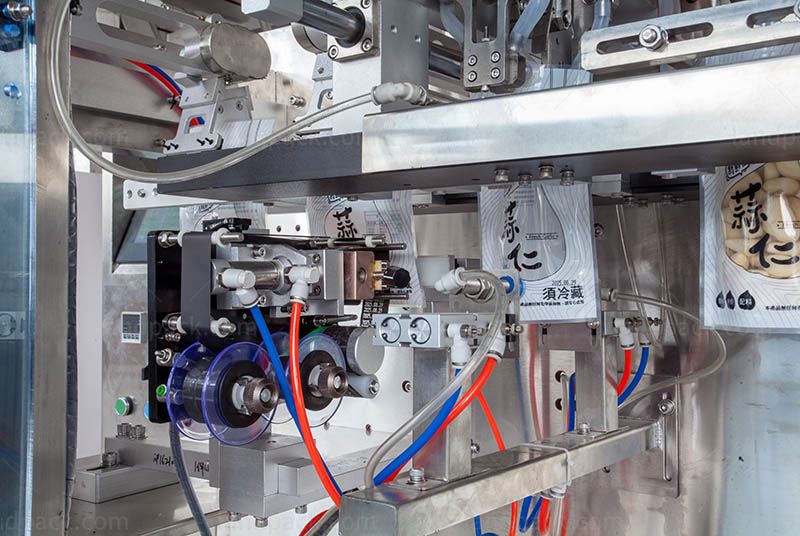

2. Pouch Opening - Dual suction pads open the pouch mouth, while mechanical guides stabilize the bag shape.

3. Accurate Multi-Head Weighing - This guarantees precise, consistent dosing for pickles, granules, nuts, and mixed snacks.

4. Product Filling - The weighed product is released into the opened pouch with synchronized timing.

5. Sealing & Coding - The top sealing jaws apply controlled heat and pressure to create a firm, reliable seal.

6. Finished Bag Discharge - Completed pouches are gently transferred to the output conveyor, maintaining pack appearance.