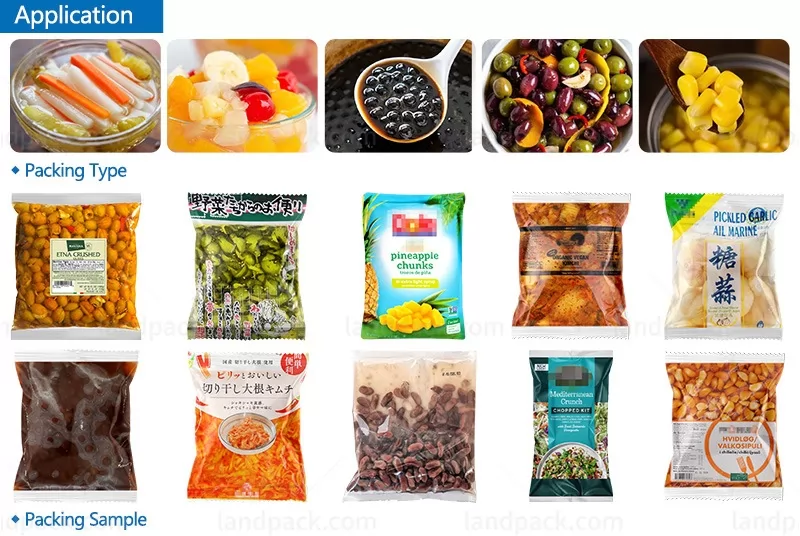

Application:

The LD-420BL vertical packaging machine is designed for combined solid and liquid packaging in one pouch. It integrates a chain plate elevator for solid products and a piston liquid filling system for sauces or brine.

Package Type:

The LD-420BL vertical packaging machine supports pillow bags, three-side seal bags, and four-side seal bags. Bag dimensions can be adjusted to accommodate different solid–liquid product ratios, ensuring stable sealing performance and consistent package appearance for mixed-content applications.

Suitable Products:

This vertical packaging machine is designed for combined solid and liquid packaging, integrating a chain-bucket elevator for granules and a piston filling system for liquids. It enables precise proportion control and stable sealing, making it ideal for products requiring both particulate and sauce or syrup in a single bag. Typical applications include:

1. Pickled & Preserved Foods: Kimchi, pickled vegetables, mixed pickles with brine, marinated radish, and fermented cabbage products.

2. Fruit & Sauce-Based Products: Fruit pieces with syrup, fruit cocktail packs, preserved fruits in juice, diced mango with syrup, and mixed fruit toppings.

3. Ready-to-Eat & Specialty Foods: Vegetable mixes with seasoning liquid, seasoned bean products, snack kits with sauce, and specialty condiment combinations.

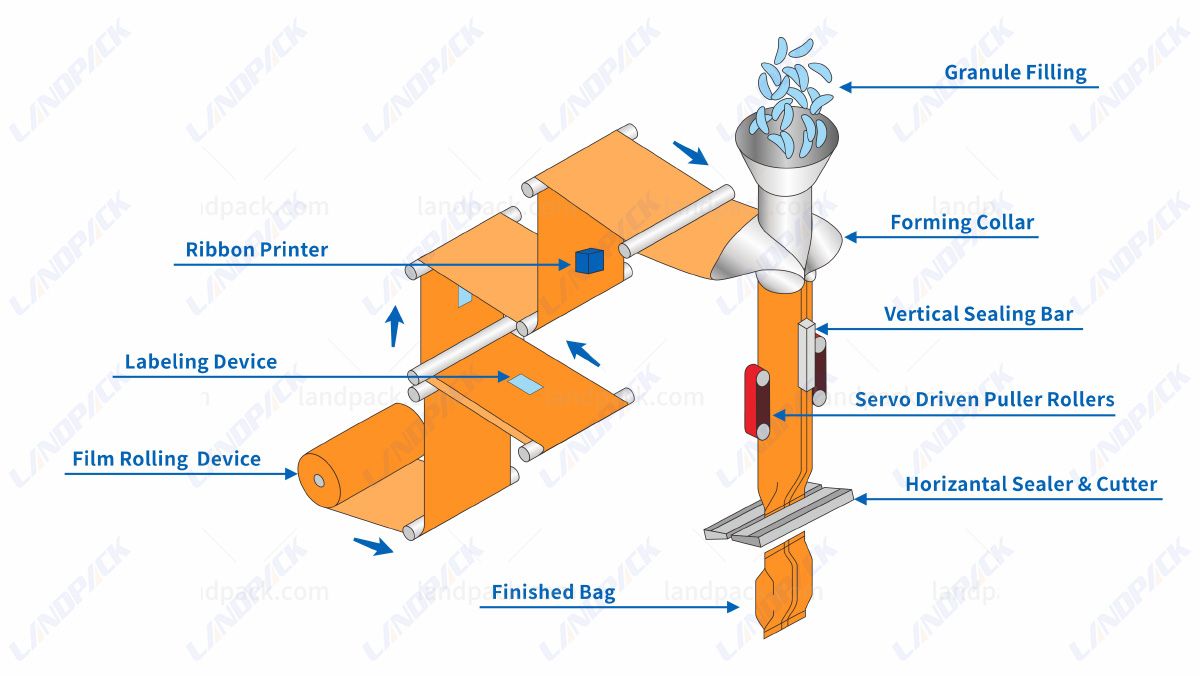

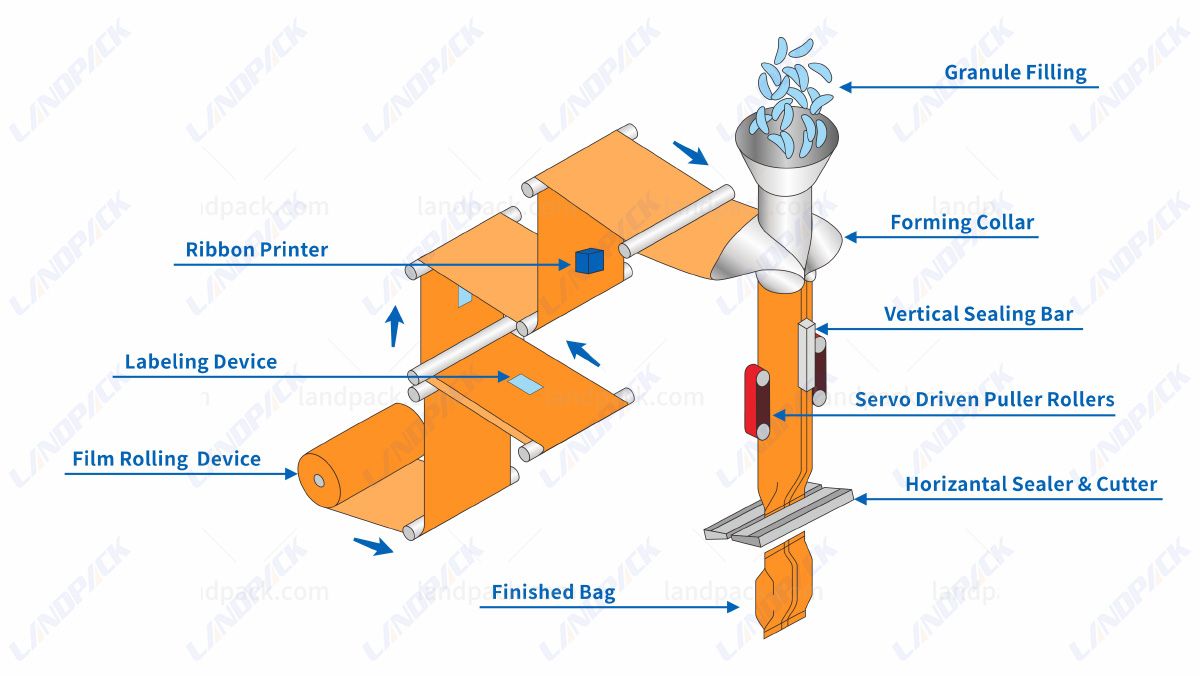

Workflow:

1. Granule Feeding: Solid materials are smoothly lifted by the chain-bucket elevator and guided into the forming system with stable, continuous feeding.

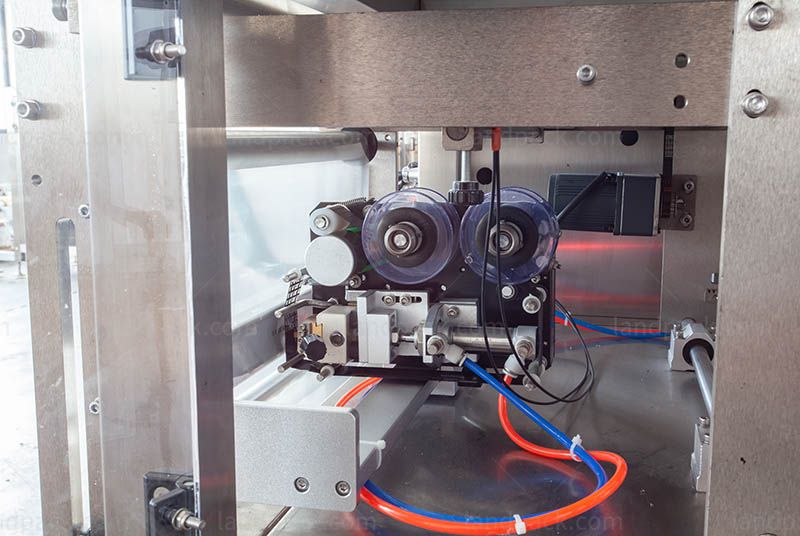

2. Liquid Dosing: The piston filling unit accurately dispenses liquid or sauce into the bag, synchronized with the granule filling process.

3. Bag Forming & Filling: Film is shaped into bags while solid and liquid components are filled in controlled proportions.

4. Sealing & Cutting: The filled bags are securely heat-sealed and precisely cut to ensure leak-free, consistent packages.