Application:

This vertical packaging machine is ideal for handling light, bulky, and fragile products, making it widely suitable for snack foods such as popcorn, cheese balls, puffed corn snacks, and caramel corn. It also supports granular and lightweight dry foods, including cereal clusters, granola bites, and small oat mixes

Package Type:

The popcorn packing machine supports a variety of snack-friendly pouch types, including back sealing pouches, pillow pouches, gusset pouches, offering excellent adaptability for popcorn, puffed food, nuts, and similar lightweight products.

Suitable Products:

This vertical packing machine, equipped with a 2-head linear weigher, is designed for efficient, gentle, and precise packaging of light, bulky, and fragile products such as popcorn. With flexible pouch size adjustment and strong compatibility with various granular and puffed snacks, the machine could pack many products from different industries:

- Snack Foods: popcorn, cheese balls, puffed corn snacks

- Granular Foods: cereal clusters, breakfast granola, oat bites.

- Confectionery & Sweets: caramel corn, sugar-coated nuts, coated candies

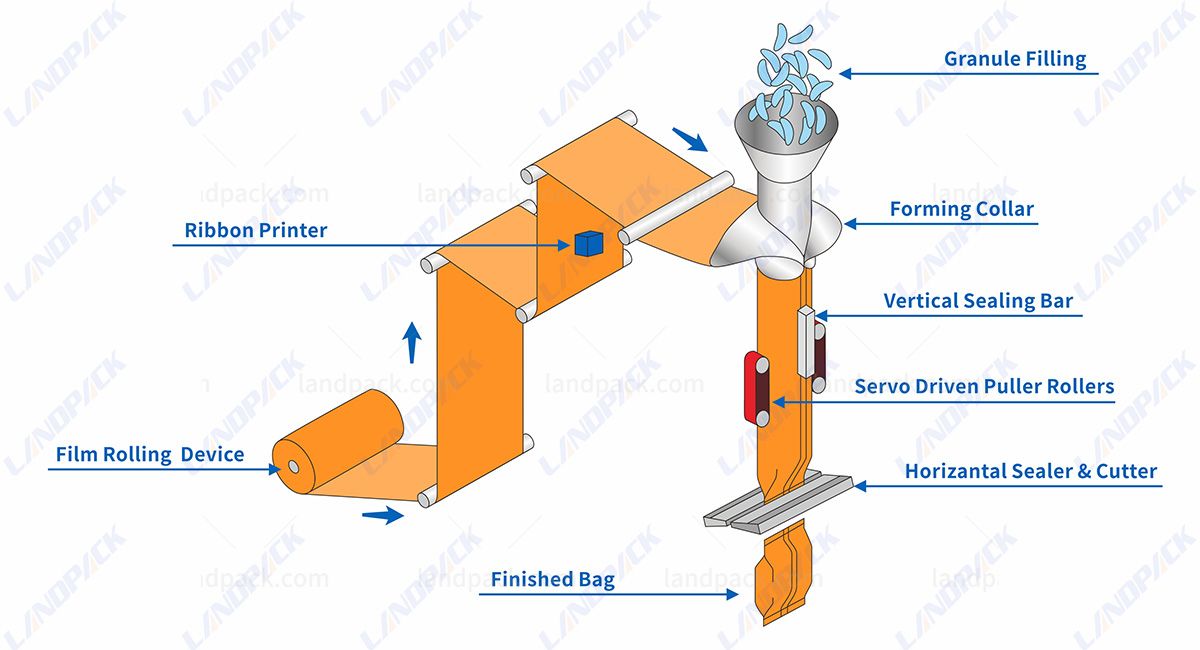

Workflow:

1. Material Feeding - Manually feed granular products such as popcorn into the hopper and wait to be weighed.

2. Two-Head Linear Weighing - Dual linear weighers measure the target weight accurately.

3. Film Pulling & Bag Forming - The machine pulls film smoothly, shapes it into a back-sealed pouch, and prepares the bag for filling.

4. Bag Opening & Filling - The formed pouch is opened, and the weighed product is filled evenly and steadily.

5. Sealing - Heat-sealing jaws close the pouch securely, maintaining freshness and preventing leakage.

6. Cutting & Output - Finished bags are cut, separated, and delivered onto the output conveyor.