Application:

High-speed rotary pouch packing machine for premade pouch packaging, handling premade pouches with precision and efficiency. Widely used in food, snacks, pet food, frozen products, daily chemicals, and pharmaceutical industries, with speeds up to 60 bags/min.

Suitable Products:

The rotary pouch packing machine is specially designed for packaging a wide variety of granule products, whether they require secondary packaging or not. With stable performance and high efficiency, it is widely used in multiple industries:

- Baking: Cakes, Chocolate Cakes, Puff Pastry, Filled Muffins

- Candy & Snacks: Chewy Caramels, Gummy Bears, Wafer Crackers, Nut & Seed Mix

- Others: Pet Food, Frozen Foods, or Frozen Meat, daily Chemicals (such as cups for mouthwash)

Flexible compatibility with a variety of kinds of pouches and products. The machine ensures precise filling, reliable sealing, and excellent product presentation, making it ideal for both primary and secondary packaging needs.

Package Type:

The Rotary Pouch Packing Machine is compatible with various premade pouch types, including zip lock bags, stand-up pouches, flat pouches, and M-shape pouches. These flexible packaging options ensure excellent product protection, reliable sealing, and extended shelf life, while also enhancing shelf appeal. With resealable and display-friendly designs, they are widely used for food, beverages, daily products, pet food, and industrial goods.

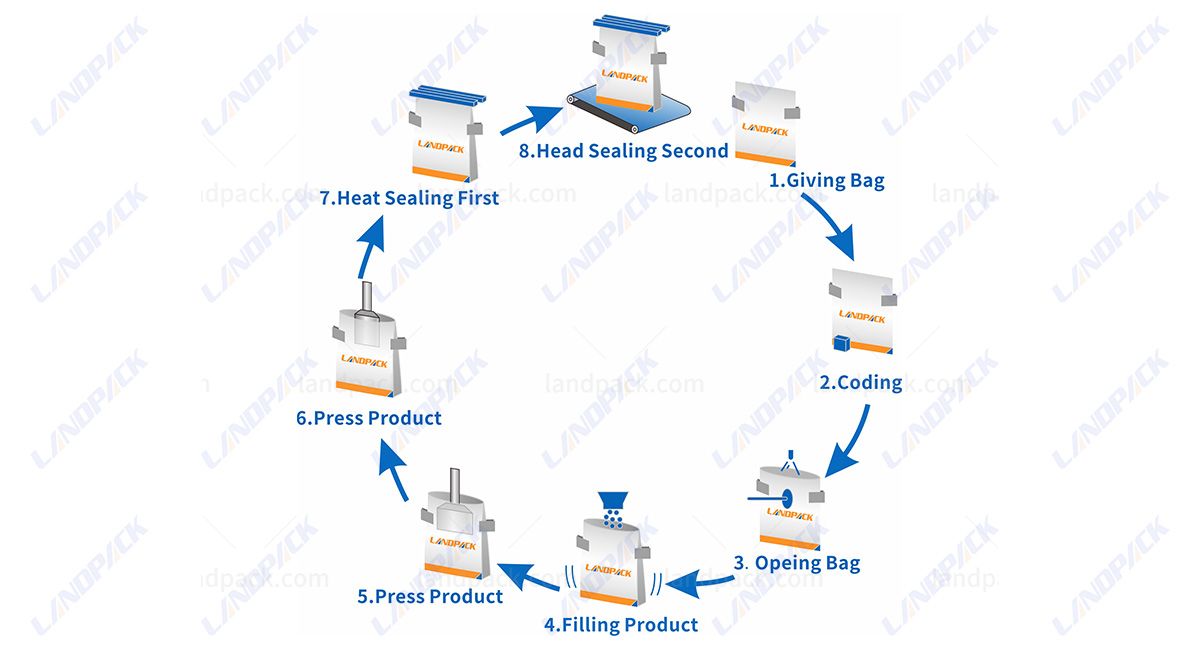

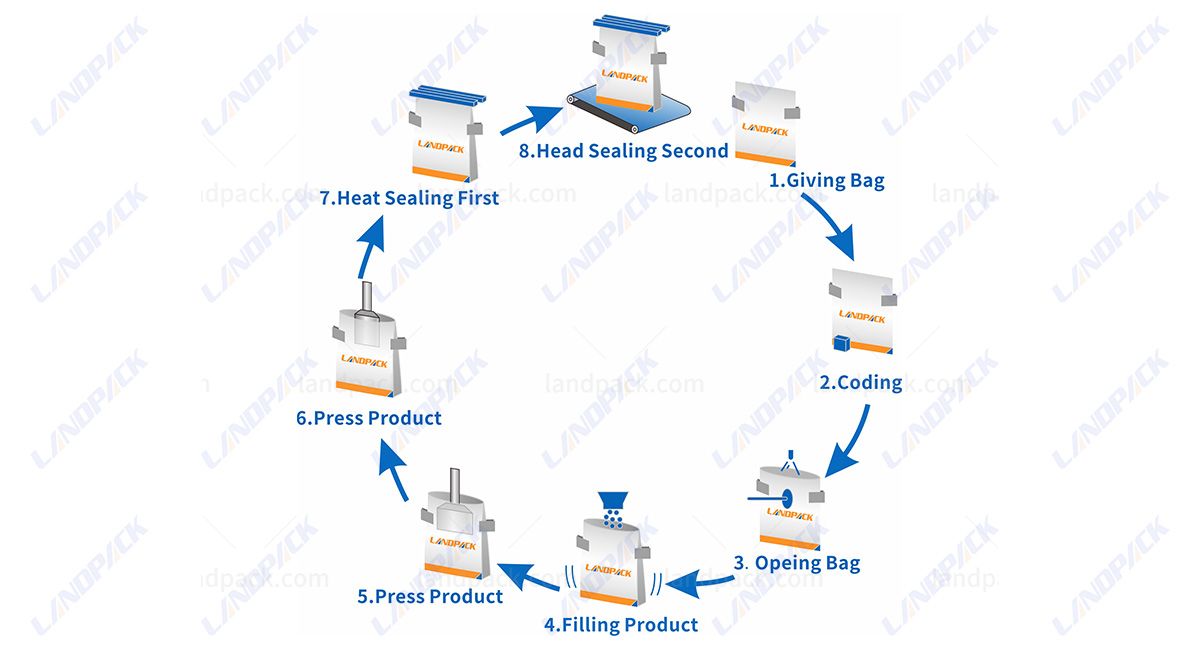

Workflow:

1. Bag Giving – The premade pouch is delivered to the machine.

2. Coding – The pouch is marked with date, batch code, or other information.

3. Bag Opening – The machine opens the pouch for filling.

4. Filling Product – The target product (powder, granules, liquid, or snacks) is filled into the pouch.

5. First Pressing – The pouch is pressed to settle the product inside.

6. Second Pressing – Ensures the product is evenly positioned for sealing.

7. First Heat Sealing – The pouch is sealed securely with heat.

8. Second Heat Sealing – This seal is reinforced to provide extra protection, assuring the package is airtight as well as secure.