Application:

This multi lane sachet/stick packing machine is ideal for liquid products such as ice pop, juice, energy gels, flavored drinks, yogurt, honey, liquid supplements, and other low-viscosity liquids. Widely used in food, beverage, health products, and daily-use liquid packaging industries.

Package Type:

This multi-lane sachet/stick packing machine supports various stick-type sachets, designed for efficient liquid and semi-liquid packaging: Standard Stick Packs (single-lane tear, narrow width), Ice Pop / Ice Lolly Stick Packs, Three-Side Sealed Stick Packs, Easy-tear Stick Pouches, Custom-size Long Strip Sachets. Perfect for juice, energy gels, cosmetic liquids, and other flowable products.

Suitable Products:

Suitable for a wide range of liquid and semi-liquid products, making it ideal for multiple industries:

- Food & Beverage Industry: Fruit juice, yogurt beverages, coffee liquids, jam, flavored drinks.

- Health & Nutrition Products: Energy gels, nutritional supplements, vitamin drinks, electrolyte liquids.

- Daily Use & Personal Care: Liquid detergent, shampoo, hand sanitizer, cosmetic liquids.

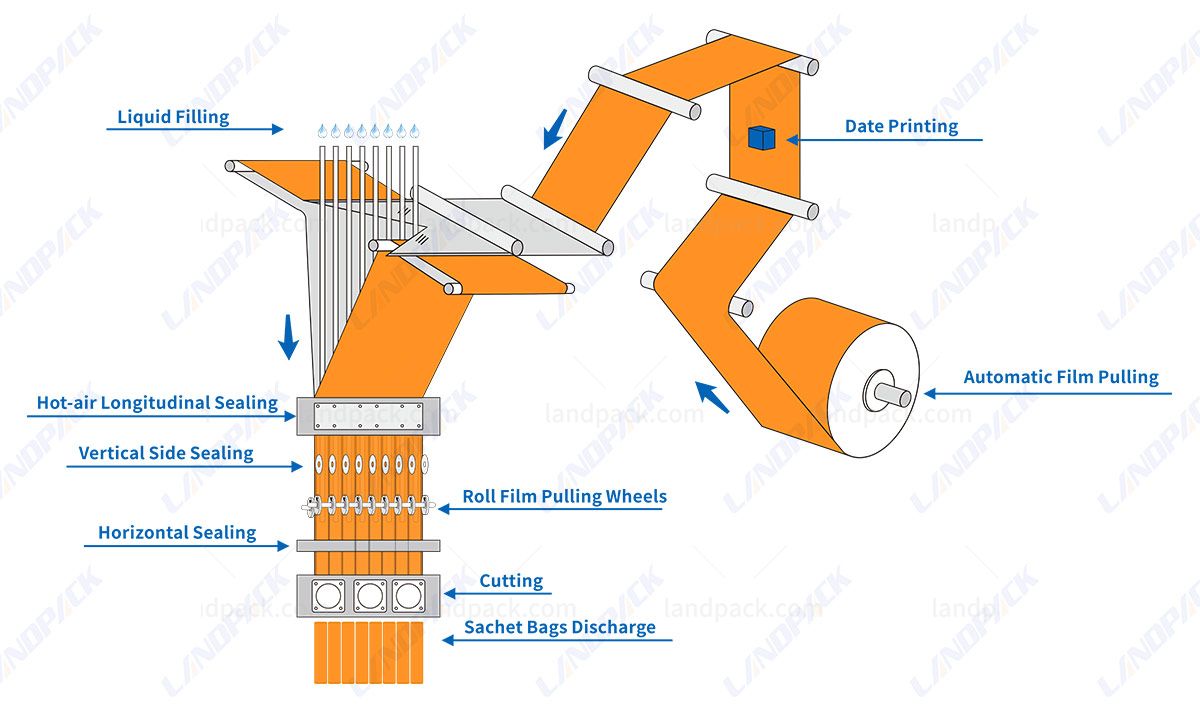

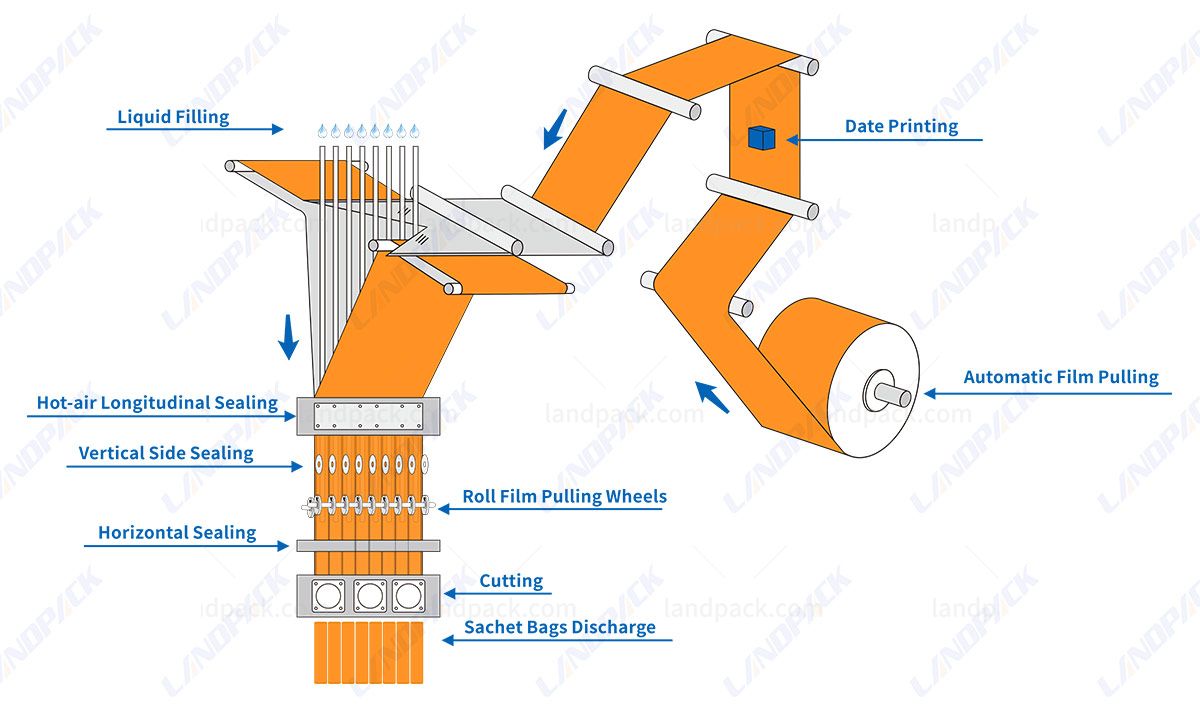

Workflow:

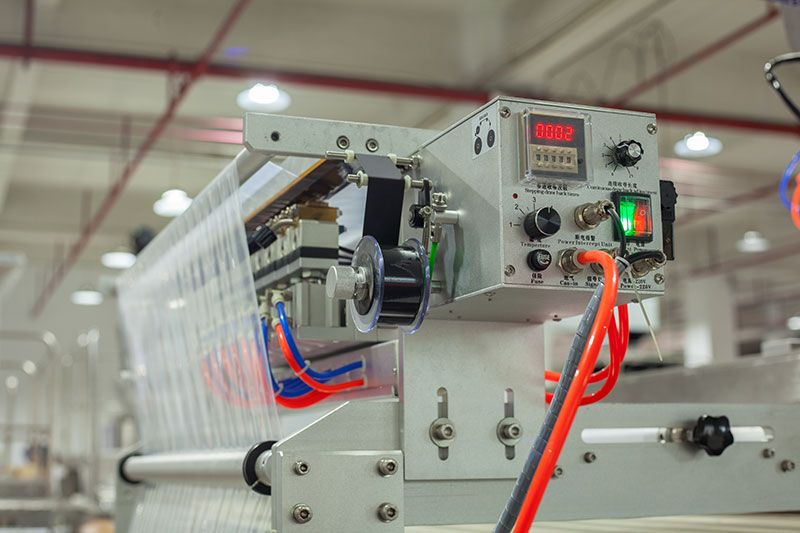

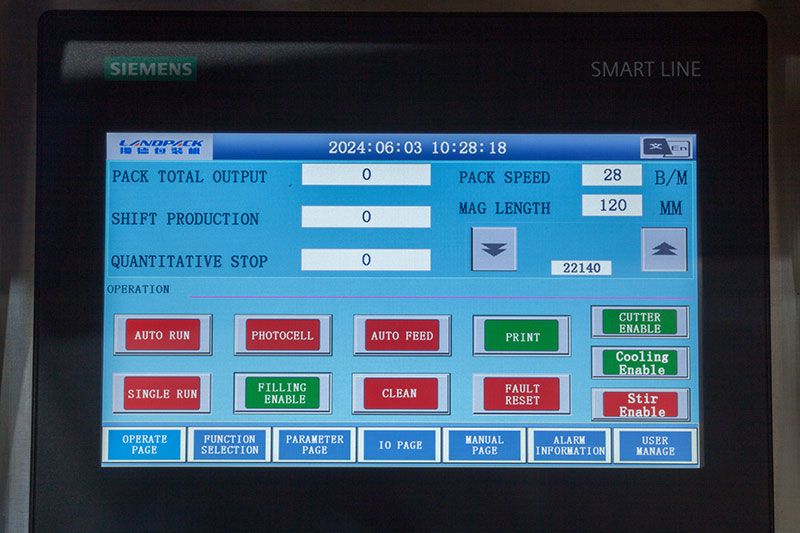

1. Film Unwinding – Roll film is automatically pulled into the machine.

2. Date Printing – Prints production or expiry date on the film.

3. Film Splitting – Film is guided and divided into multiple lanes.

4. Liquid Filling – Each lane is filled simultaneously.

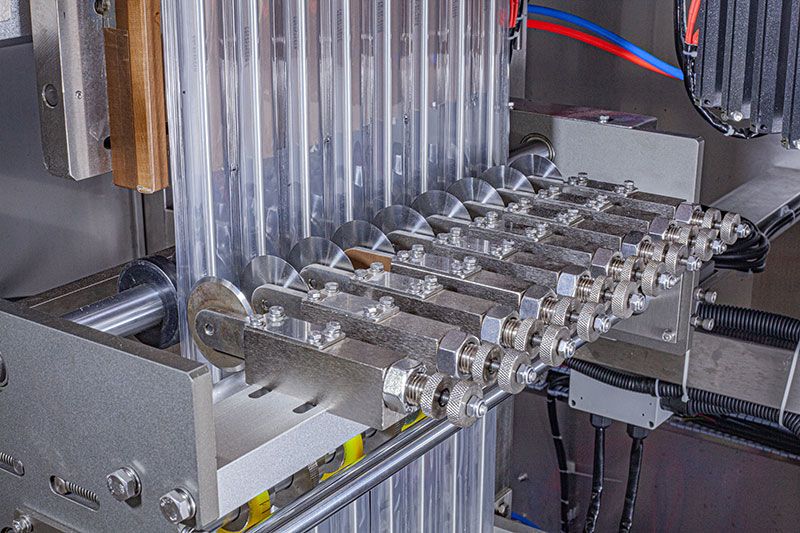

5. Vertical Sealing – Forms strong longitudinal and side seals.

6. Horizontal Sealing – Seals the top and bottom of each stick.

7. Cutting – Cuts the film into individual sticks.

8. Discharge – Finished stick packs are output.