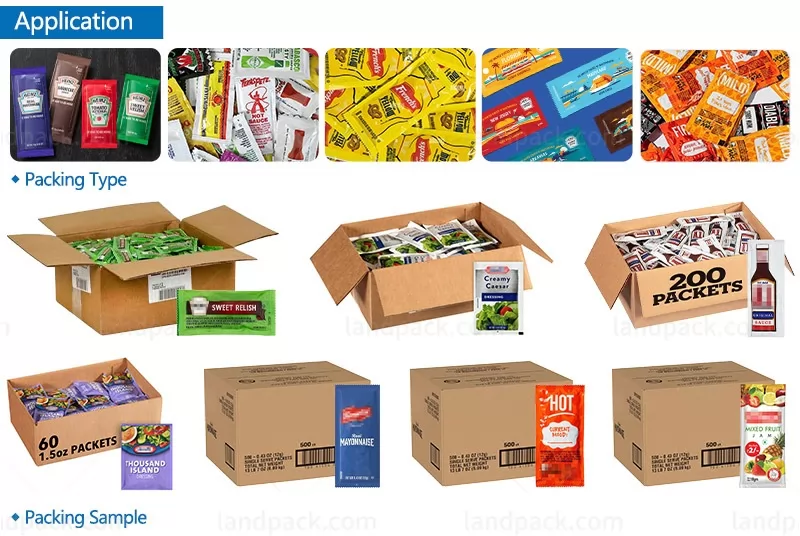

Application:

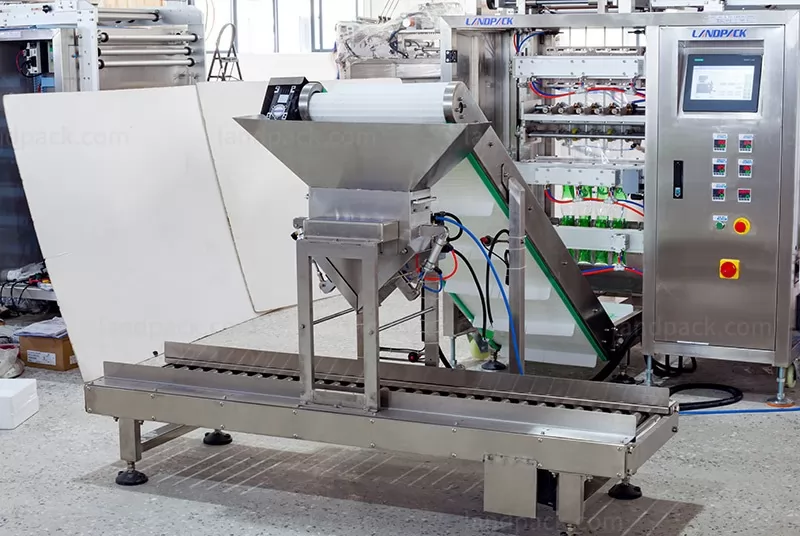

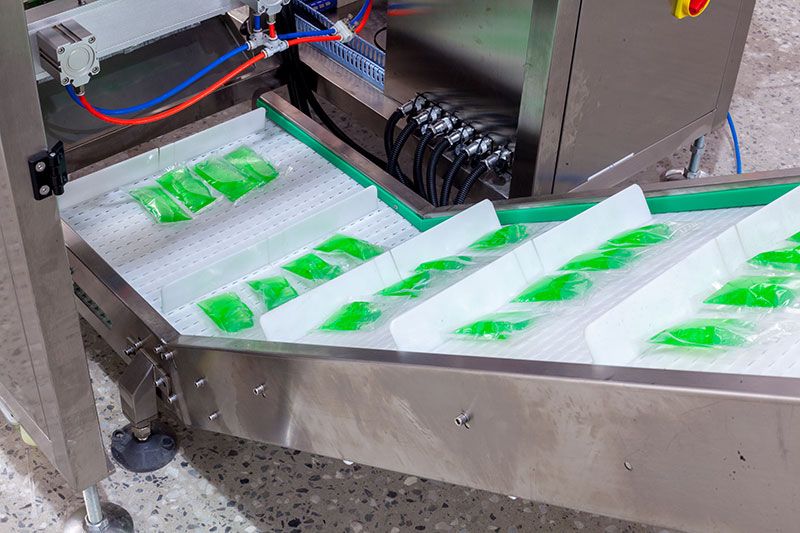

This 4 Lane Liquid Sauce Sachet Counting Packaging Line is used to package liquid and semi-liquid items such as tomato ketchup and sauces, mayonnaise and salad dressings, honey and vinegar, shampoo, and soy sauce. It is suitable for sealing sachets with a 4 or 3-sided seal. The machine ensures accurate measuring, high speed filling and consistent sealing. Ideal for the food, cosmetic, and condiment industries that require compact and efficient paste packaging machines.

Package Type:

Suitable for liquid sachets (3/4 side seal, stick). Integrated counting & cartoning unit automatically arranges sachets into boxes or cartons for secondary packaging.

Suitable Products:

The Landpack High-speed 4 Lane Liquid Sauce Sachet Counting Packing Line is designed for efficient, precise, and hygienic packaging of various liquid and semi-liquid products as below

- Food Sauce: Tomato ketchup, salad dressing, chili sauce, soy sauce.

- Condiment: Vinegar, sweet paste, oyster sauce, mustard.

- Liquid Paste: Honey, jam, syrup, peanut butter.

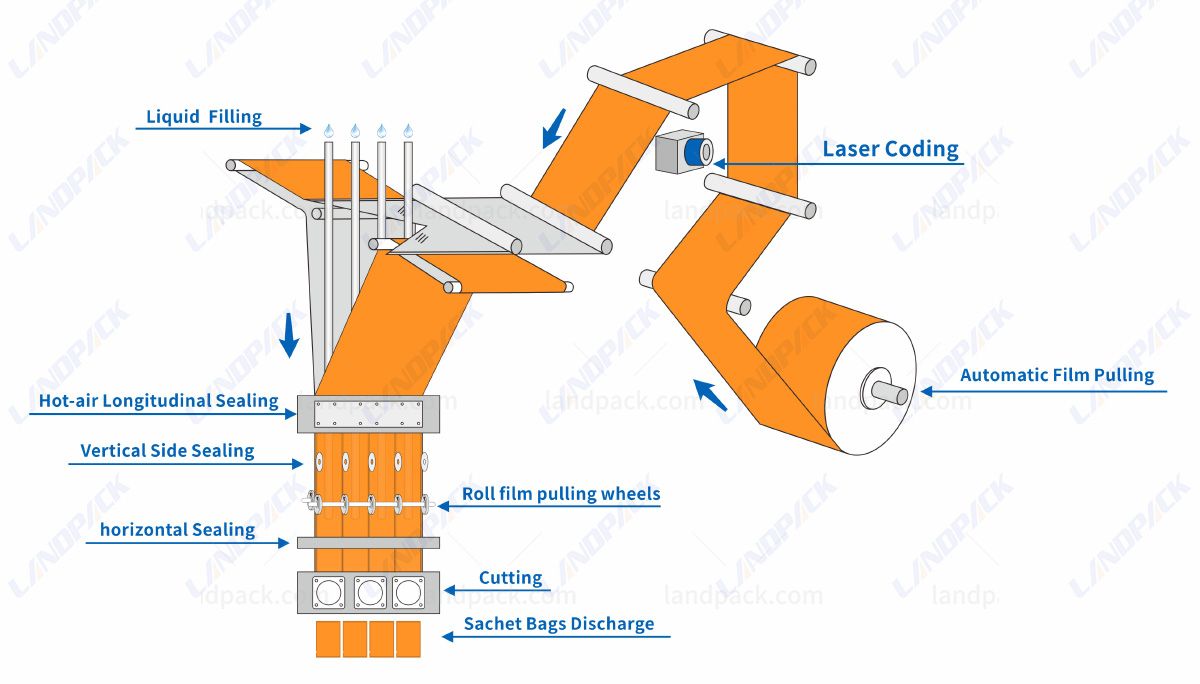

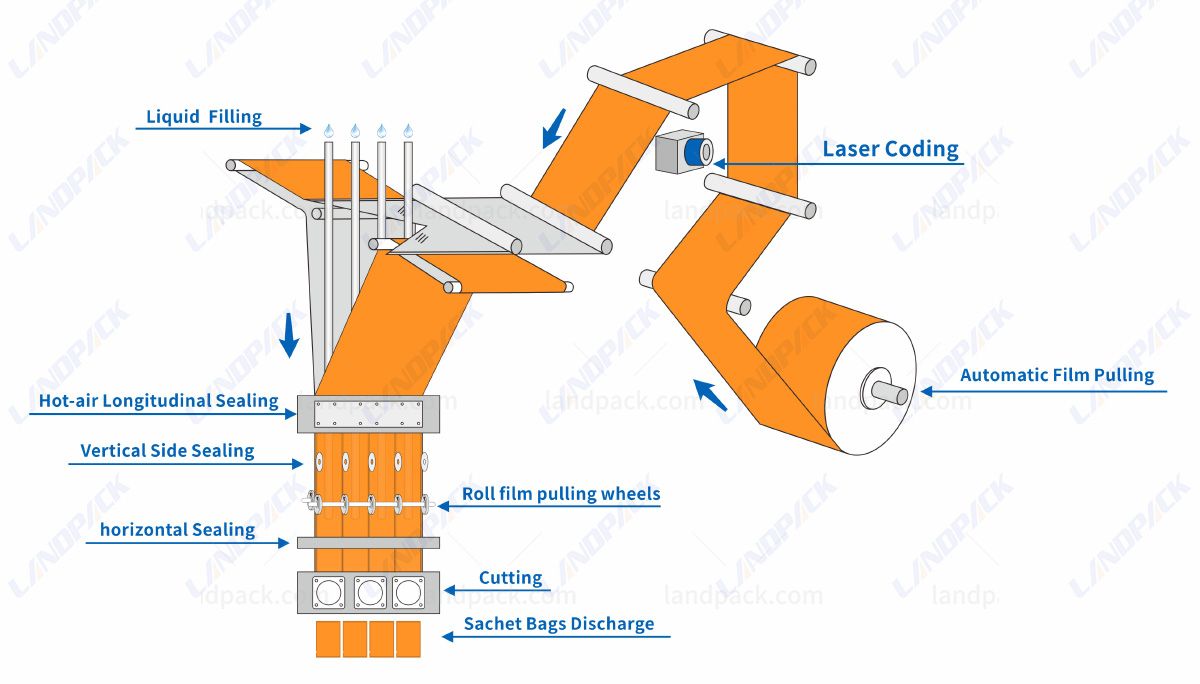

Workflow:

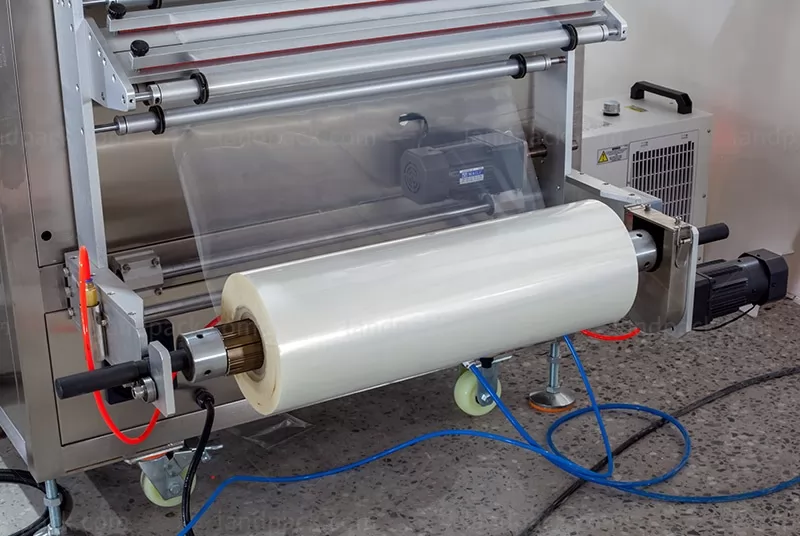

1. Automatic Film Pulling – The roll film is automatically unwound and aligned for precise bag forming.

2. Laser Coding – Prints clear production date or batch number on the film before filling.

3. Liquid Filling – Each lane accurately fills the preset amount of sauce, paste, or liquid into the sachets.

4. Hot-air Longitudinal Sealing – Forms the vertical seal using constant-temperature hot air for leak-proof pouches.

5. Vertical Side Sealing – Ensures each lane's side edges are tightly sealed and uniform.

6. Roll Film Pulling Wheels – Pulls the film steadily to maintain tension and bag length accuracy.

7. Horizontal Sealing – Creates the top and bottom seals for each sachet to ensure strong sealing.

8. Cutting – The machine precisely cuts individual sachets from continuous film strips.

9. Sachet Bags Discharge – Finished sachets are automatically discharged and transferred to the counting and boxing system.