Application:

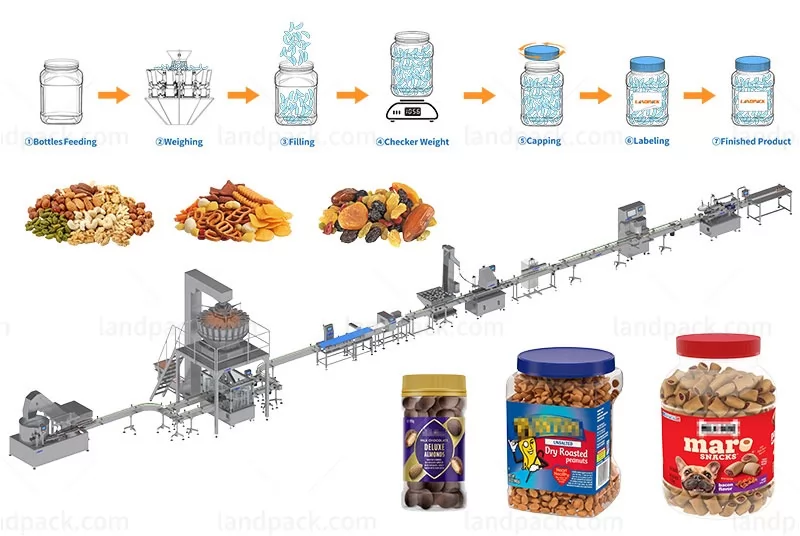

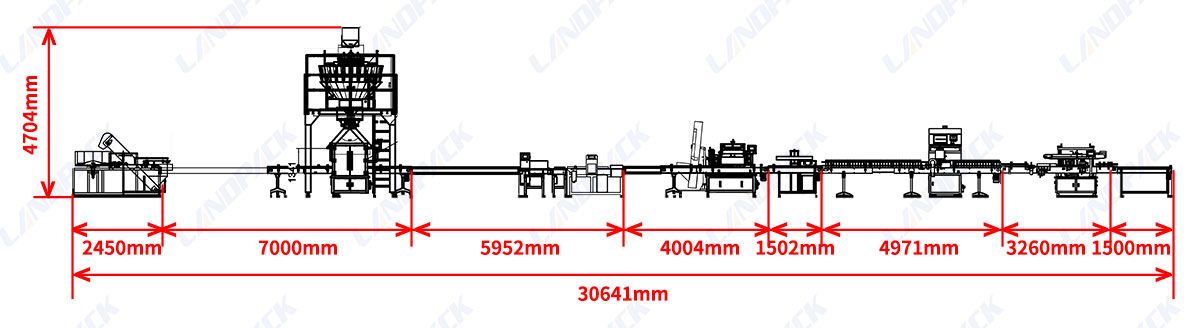

This spice bottle filling machine is designed for fully automatic filling, capping, and labeling of seasoning and spice products in bottles. With a working speed of up to 50 bottles/min, it is widely used for spices, seasoning, chili, pepper, cumin seeds, and blended seasonings.

Package Type:

This spice bottle filling machine is compatible with various bottle and cap styles for granular seasoning products, ensuring flexible and precise packaging. Such as Glass Bottles, PET Bottles, Plastic Bottles, Aluminum Bottles (optional), Screw Caps, Flip-Top Caps, Shaker Caps, etc.

Suitable Products:

This spice bottle filling machine is suitable for accurate filling of various granular seasoning materials, ensuring stable dosing and clean operation. Such as Black Pepper Granules, White Pepper Granules, Chili Flakes, Sesame Seeds, Cumin Seeds, Mustard Seeds, Dried Garlic, Granules, Mixed Granular Seasonings and other granules materials.

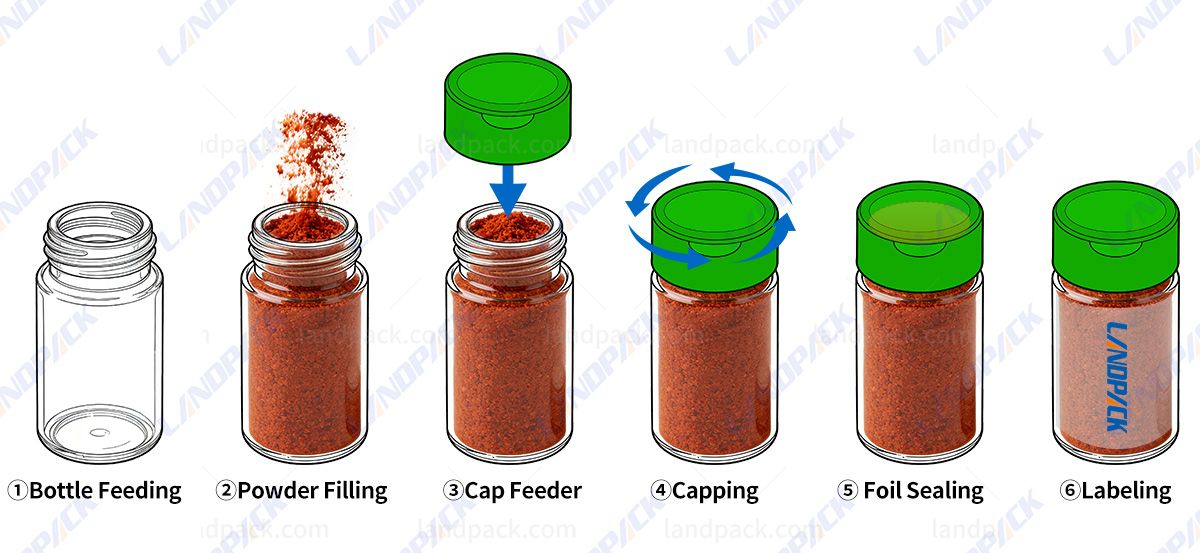

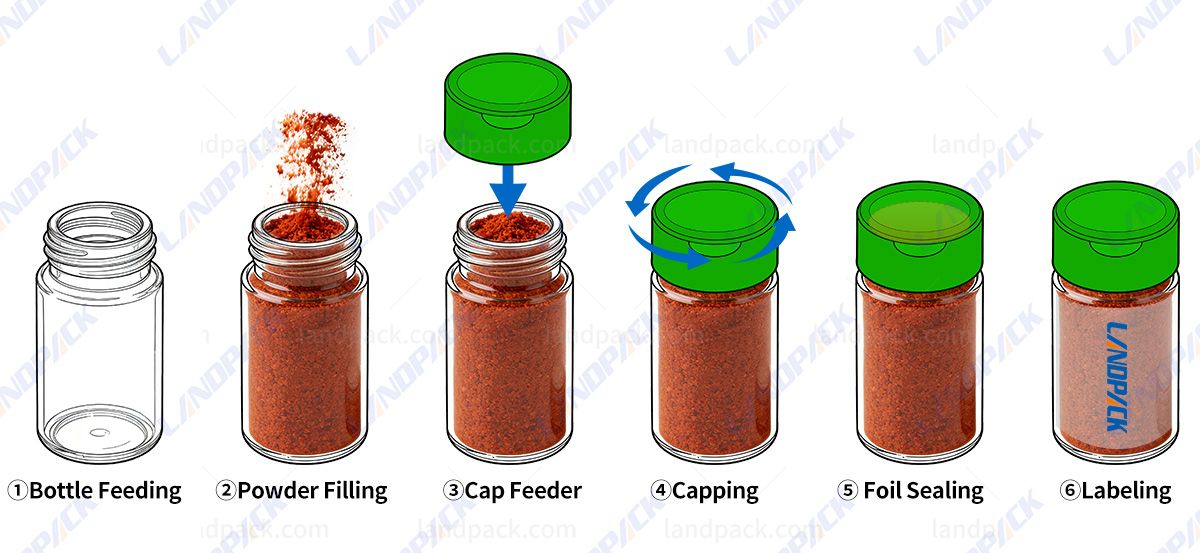

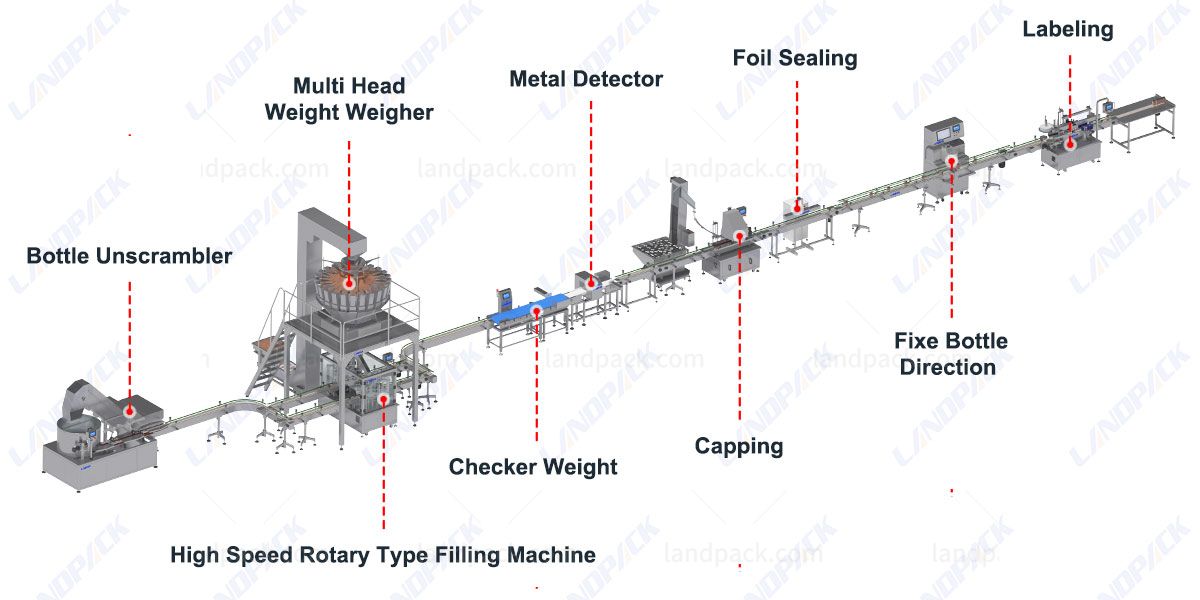

Workflow:

1. Bottles Feeding – Automatically feeds empty bottles into the line

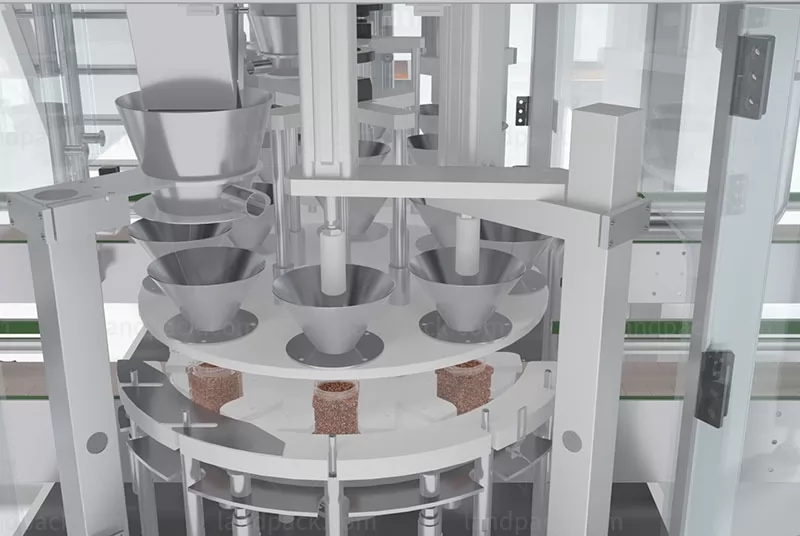

2. Material Weighing – Accurately measures spice quantity for each bottle

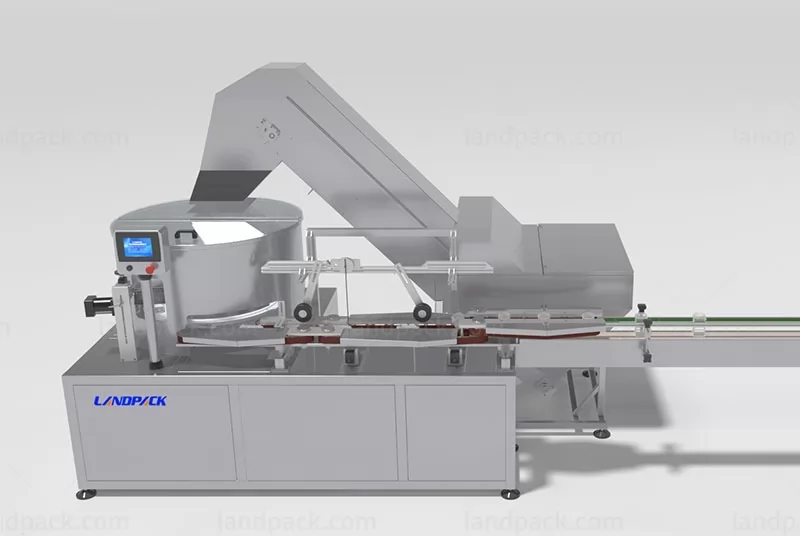

3. Rotary Filling – Fills bottles with granular spice in high speed

4. Weight Checking – Ensures correct weight for each bottle

5. Metal Detecting – Detects metal contaminants for safety

6. Capping – Automatically caps bottles securely

7. Foil Sealing – Seals bottles with protective foil (if needed)

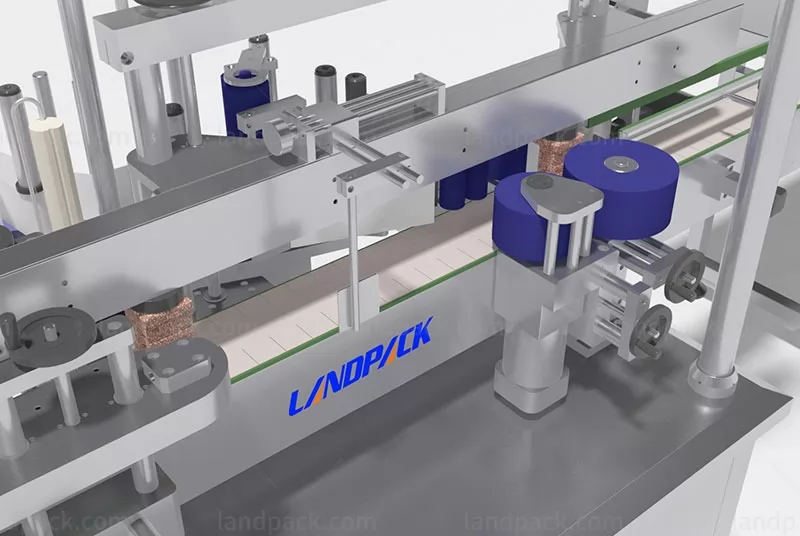

8. Vision Inspection – Adjusts bottle direction for proper labeling

9. 3-Side Labeling – Applies accurate and consistent labels

10. Output and Collecting – Finished bottles are discharged for packaging or next step