Application:

This Horizontal Vegetable Fruit Pepper In Tray Packing Machine is ideal for high-speed packaging of fresh fruits and vegetables in trays or pillow-style packs. It is widely used for apples, oranges, tomatoes, cucumbers, carrots, leafy vegetables, mushrooms, berries, and other fresh produce, ensuring hygienic packing, attractive presentation, and extended shelf life for retail and supermarket distribution.

Packaging Style:

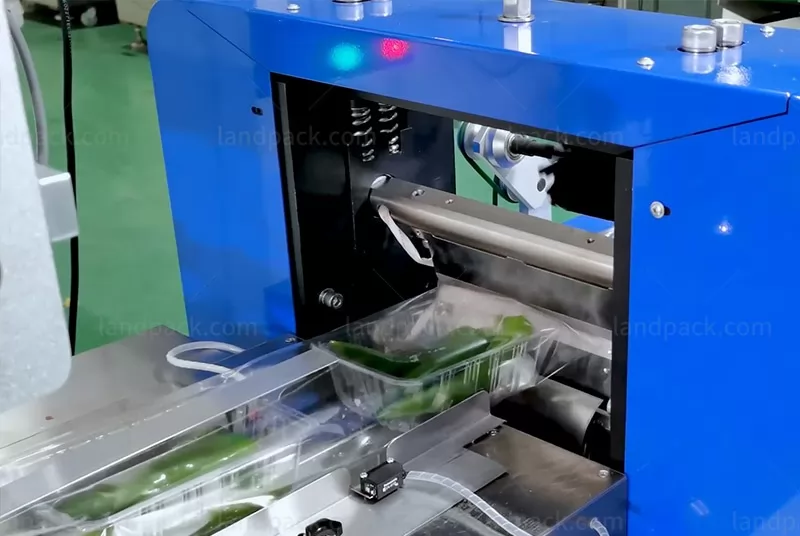

Suitable for various fresh produce packaging formats, including Plastic trays (PET, PP, PS), Paper trays and eco-friendly fiber trays, Tray packs with or without absorbent pads, Pillow-style packs for loose fruits and vegetables. Compatible with different tray sizes and shapes for supermarket and retail packaging.

Wide Application Range:

It is designed to be efficient and clean packaging of a broad range of fresh products. It can handle both individual items as well as mixed trays with ease of handling and steady output.

- Fresh Vegetables: Tomatoes, chili peppers, cucumbers, baby corn

- Fresh Fruits: Apples, pears, citrus fruits, avocados

- Fresh Produce Packs: Mixed vegetable trays, fresh-cut vegetables, ready-to-cook produce sets, vegetable salads

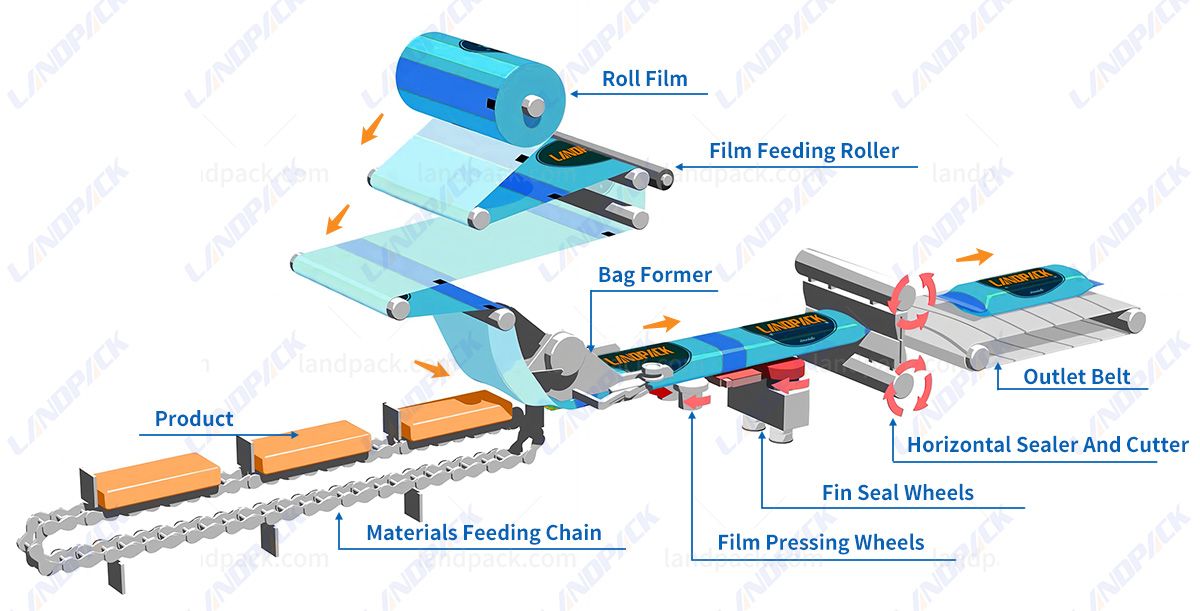

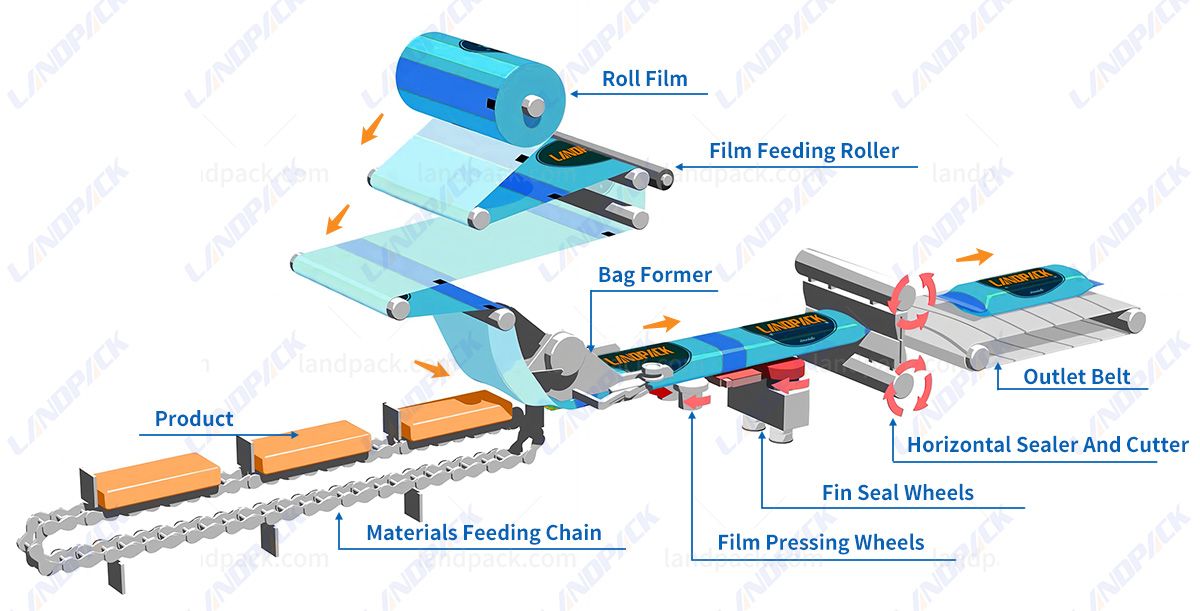

Process Workflow:

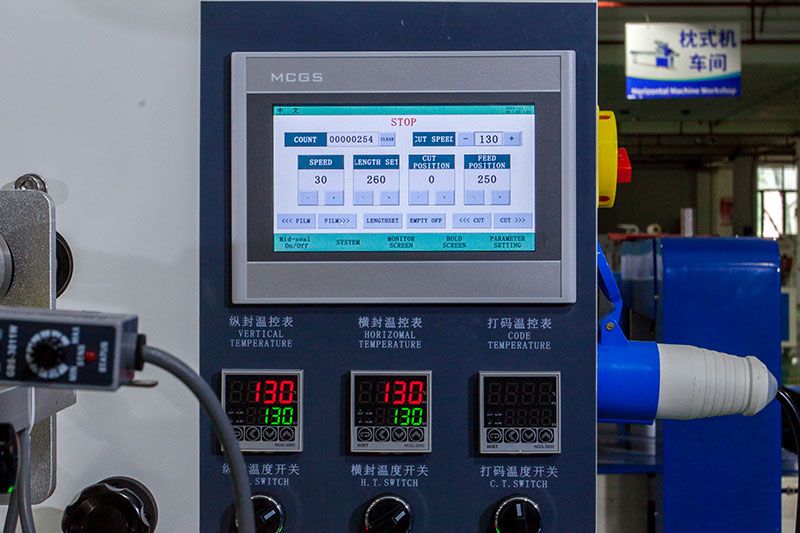

1. Material Feeding: Fruits or vegetables are conveyed smoothly into the packing area.

2. Film Feeding: Packaging film is automatically unwound and guided into position.

3. Bag Former: Film is shaped around the product or tray.

4. Film Press: Film is pressed firmly for a neat and stable wrap.

5. Fin Seal: Longitudinal sealing ensures strong back sealing.

6. Horizontal Sealing & Cutting: Ends are sealed and cut to form individual packs.

7. Output: Finished packages are discharged for collection or downstream processing.