Application:

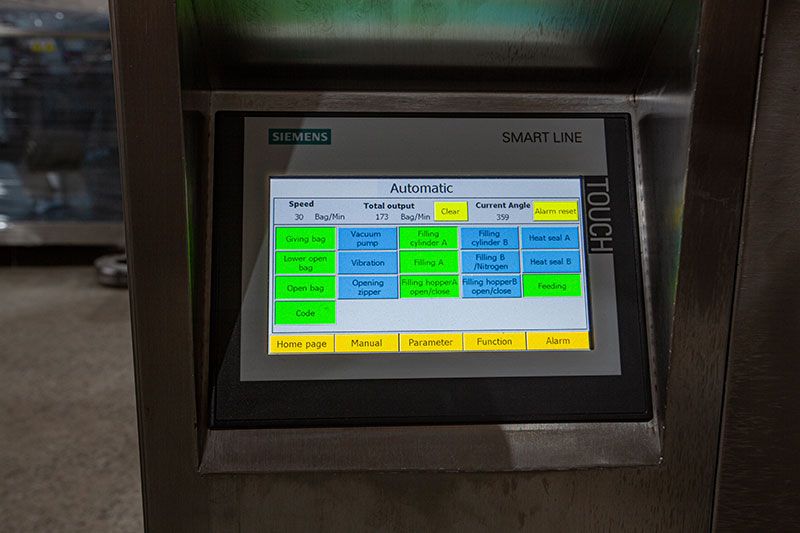

The Automatic Rice Packing Machine is designed for fast and precise premade pouch filling and sealing of granular products at up to 50 bags/min. It is ideal for packaging rice, grains, beans, lentils, seeds, sugar, salt, dry food granules, and similar free-flowing materials. Widely used in food packaging equipment production lines, this granule packing machine offers stable performance, clean operation, and consistent sealing quality - making it a smart choice for brands seeking reliable automation from a professional packaging machine manufacturer.

Package Type:

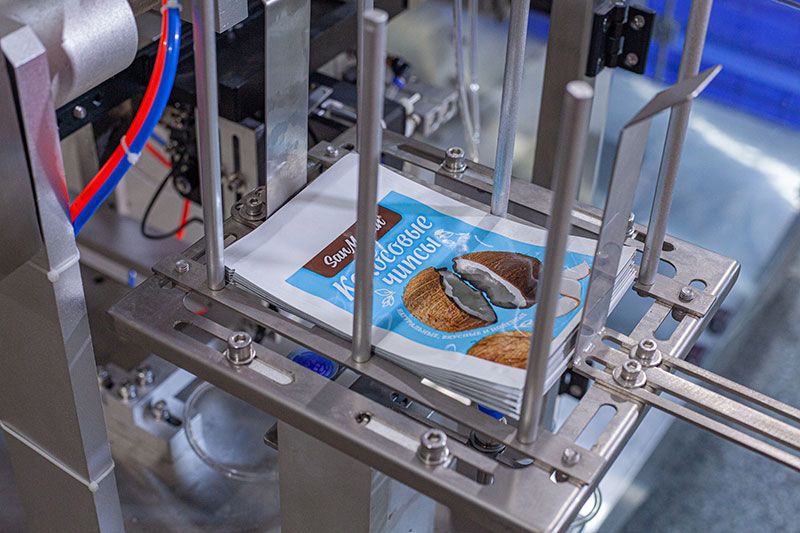

This automatic rice packing machine is compatible with a wide range of premade pouches, stand-up pouches, zipper pouches, gusset pouches, etc, ensuring clean filling, strong sealing, and high presentation quality for retail and wholesale packaging.

Suitable Products:

This rice packing machine was made to handle a large assortment of granular goods with stable accuracy and clean filling that making it suitable for both food and non-food sectors.

- Grains & Cereals: Rice, Millet, Sorghum, Barley

- Beans & Pulses: Red beans, Mung beans, Black beans, Chickpeas

- Other Granular Products: Seeds, Sugar, Chicken bouillon granules, Laundry detergent

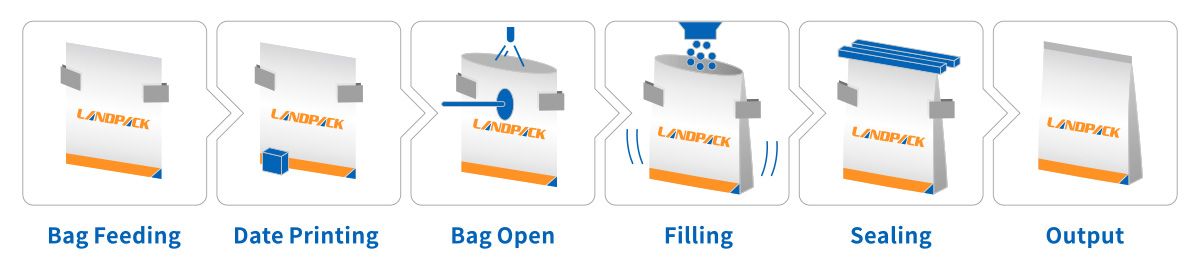

Workflow:

1. Bag Feeding: Automatically takes out premade pouches from the magazine of the bag and places them on the grippers.

2. The Date Printer: This device codes and prints the date of production batch numbers or designs on the bag before filling.

3. Bag Opening: Two suction nozzles allow the pouch to be opened securely and the machine moulds it gently to ensure steady filling.

4. Filling: The dosing device gives the proper quantity of product, such as rice, grains, beans, powders or grains into the pouch that is opened.

5. Sealing: The pouch's top is sealed using pressure and heat to create an airtight, strong seal.

6. Output: The completed sealed pouch is pushed onto the conveyor at the output, ready to be packed or cartoned.