Application:

This 8-head pesticide filling machine is widely used for packaging a broad range of low- to medium-viscosity liquids across multiple industries. It is suitable for agrochemical products such as liquid fertilizers, laundry detergent, hand wash, and dishwashing liquid; and various food-grade liquids such as soy sauce, vinegar, cooking wine, and other thin sauces.

Package Type:

The 8-head liquid filling machine is compatible with a wide variety of container types, including PET, HDPE, and PP plastic bottles, glass bottles, and chemical-resistant containers commonly used for pesticides and industrial liquids.

Suitable Products:

The automatic liquid filling machine is designed for smooth, low-to-medium viscosity liquids that require accurate dosing,making it suitable for multiple industries including chemicals, agrochemicals, household products, and food processing.

- Agrochemical & Pesticide Liquids: Insecticides, Fungicides, Herbicides.

- Chemical Products: Liquid Fertilizer, Industrial Cleaners, Surface Treatment Solutions.

- Household & Daily Chemical Products: Laundry Detergent, Hand Soap / Hand Wash, Dishwashing Liquid.

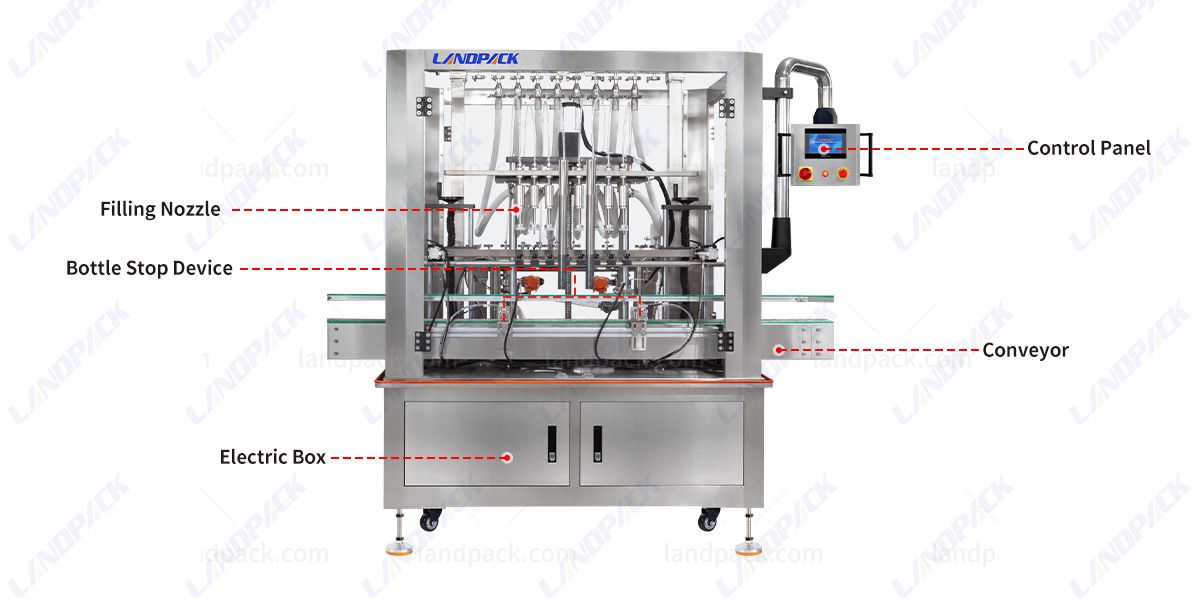

Workflow:

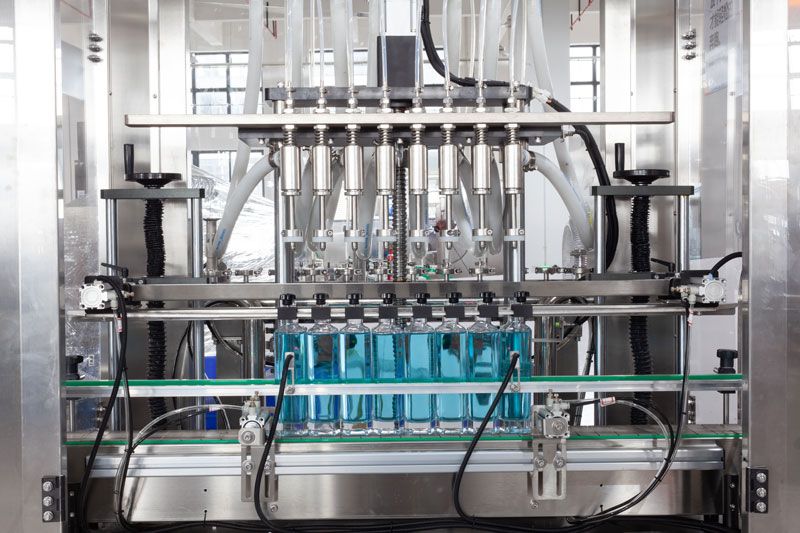

1. Bottle Feeding - Bottles that are empty are repositioned and automatically transferred into the filling station in a continuous, stable order.

2. Sensors detect bottles - They verify the alignment and presence of each bottle.

3. Vacuum-Assisted Filling - The eight heads of filling utilizes negative pressure to force liquid from the bottles effortlessly.

4. Bottle Discharge - Bottles that have been filled are moved onto the station next ready to be capping, labeling or downstream packaging.