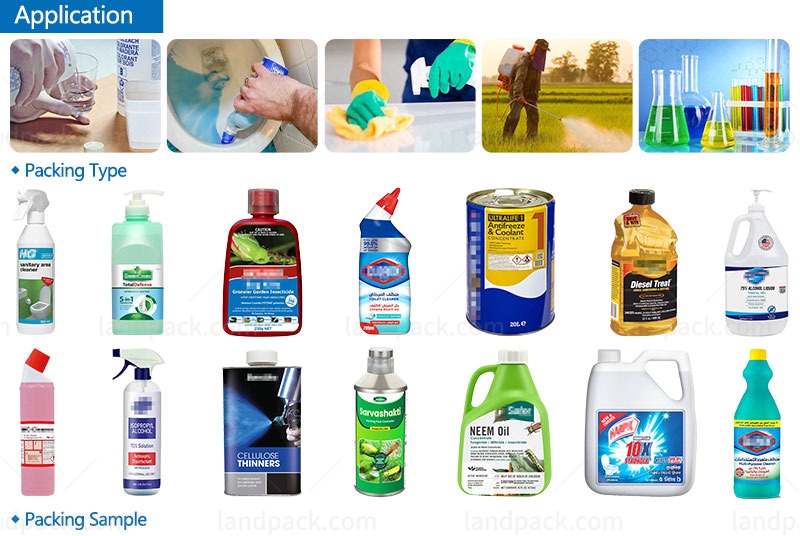

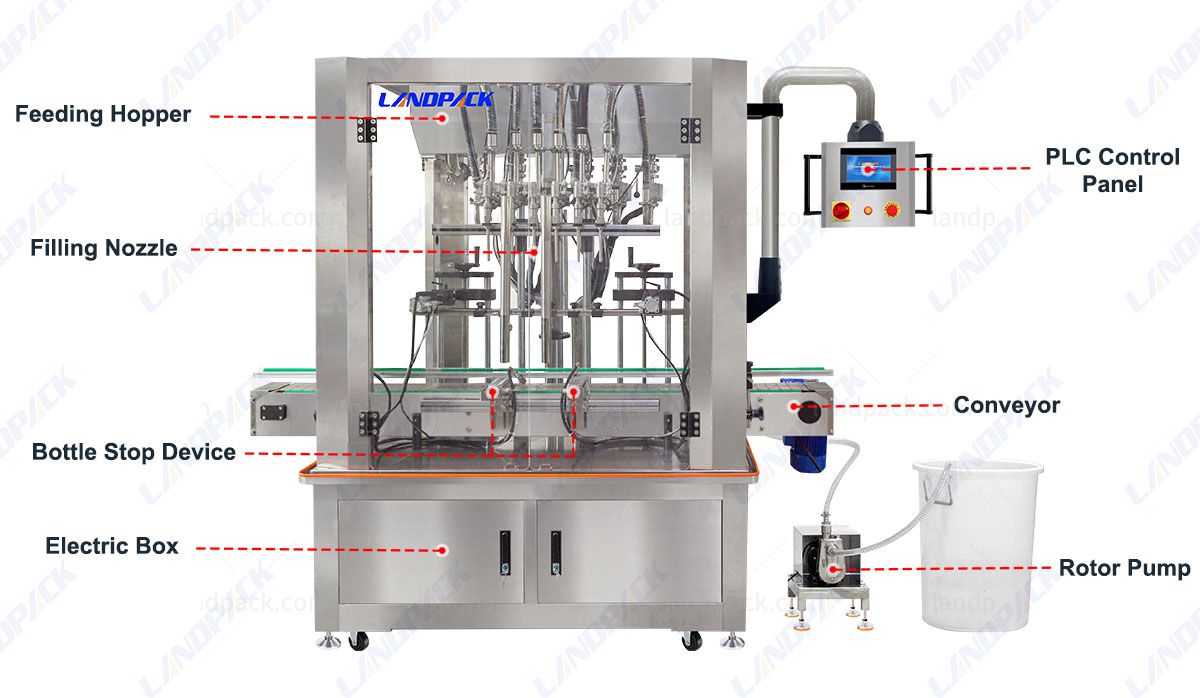

Application:

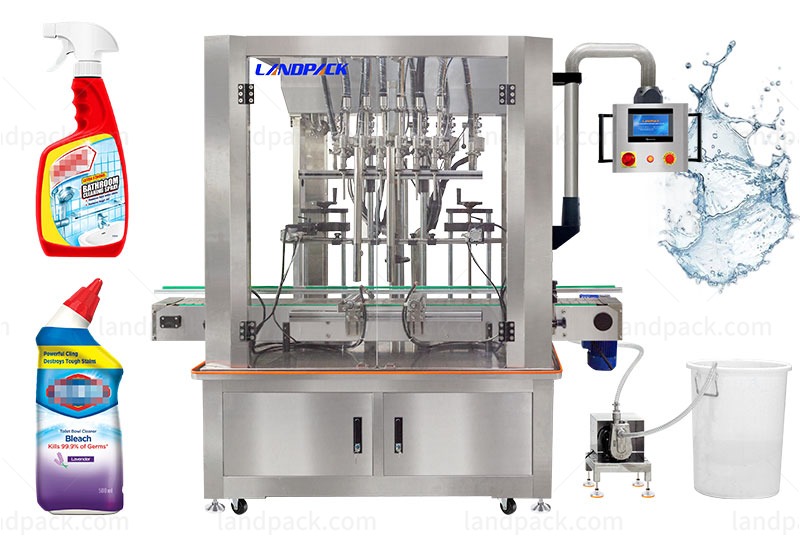

This corrosive liquid filling machine is suitable for accurate and safe bottling of chemical and sanitary liquid products, including acids, alkalis, and viscous gels. It is widely used for filling detergents, disinfectants, cleaners, bleach, hand sanitizers, industrial chemicals, and other corrosive or semi-corrosive liquids into various bottles, delivering stable output up to 60 bottles/min with consistent filling accuracy and high production efficiency.

Package Type:

This corrosive liquid & sanitary gel filling machine is compatible with a wide range of chemical-grade containers, ensuring safe filling, tight sealing, and stable operation for corrosive and viscous liquids. Such as plastic bottles (HDPE, PP, PET), chemical-resistant bottles, round, square, and oval bottles, small to medium volume containers, customized bottle shapes upon request

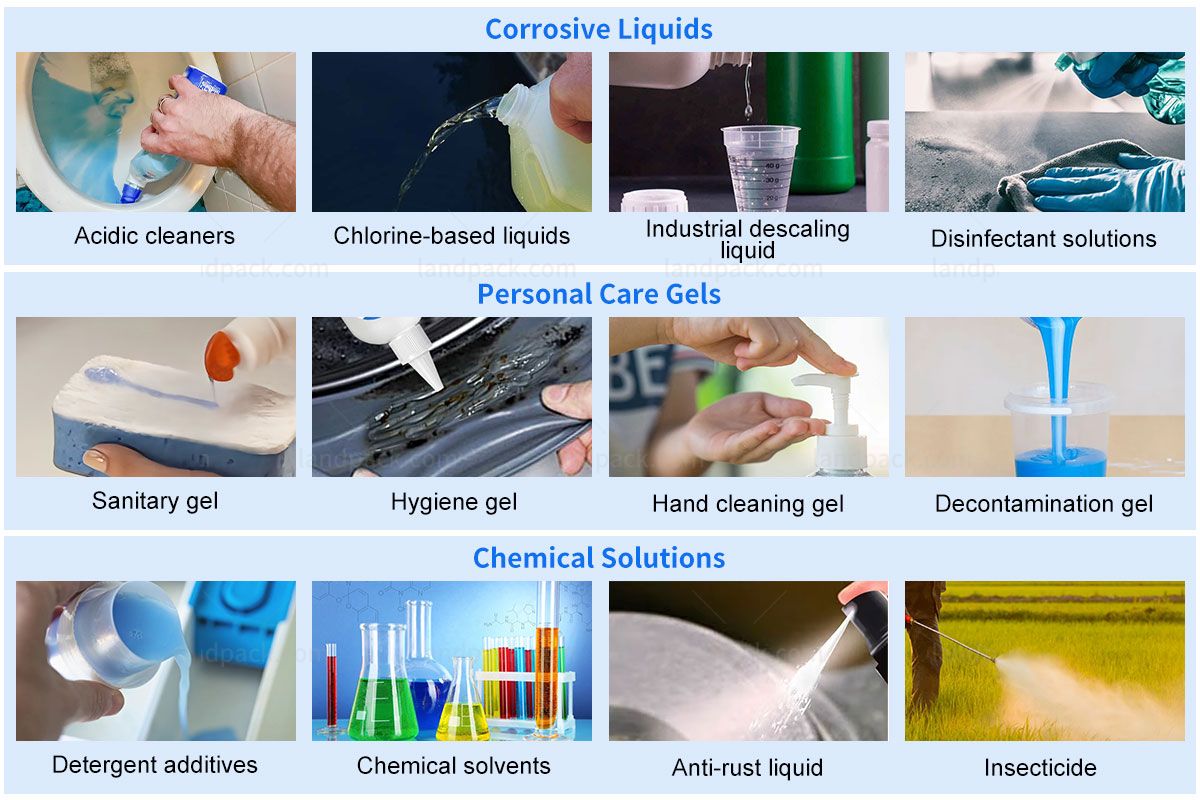

Suitable Products:

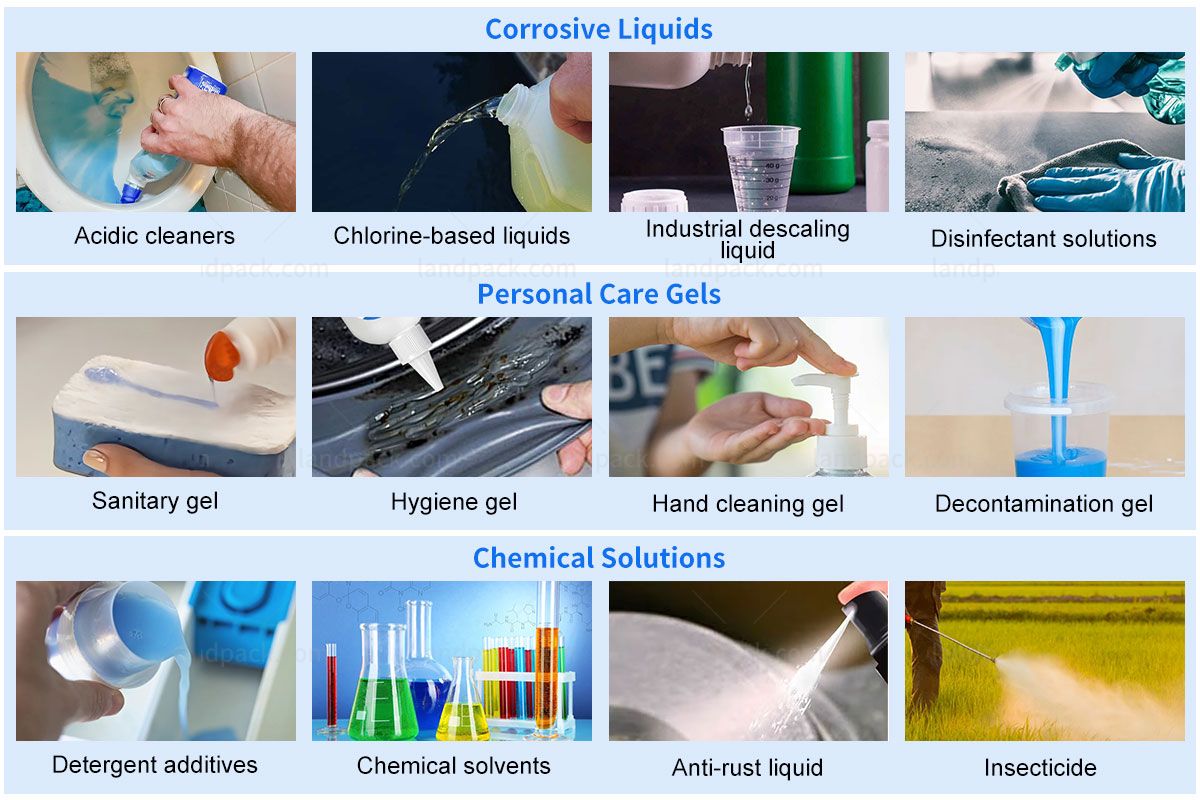

This corrosive filling machine is specifically made to handle a diverse assortment of corrosive liquids chemical solutions and the sanitary gels. With its corrosion-resistant components as well as precise filling controls this machine assures stable, safe, and precise packaging for personal and industrial use.

- Corrosive Liquids: Acidic cleaners, chlorine-based liquids, industrial descaling liquids, disinfectant solutions

- Personal Care Gels: Sanitary gel, hygiene gel, hand cleaning gel, decontamination gel

- Chemical Solutions: Detergent additives, chemical solvents, anti-rust liquids, insecticides

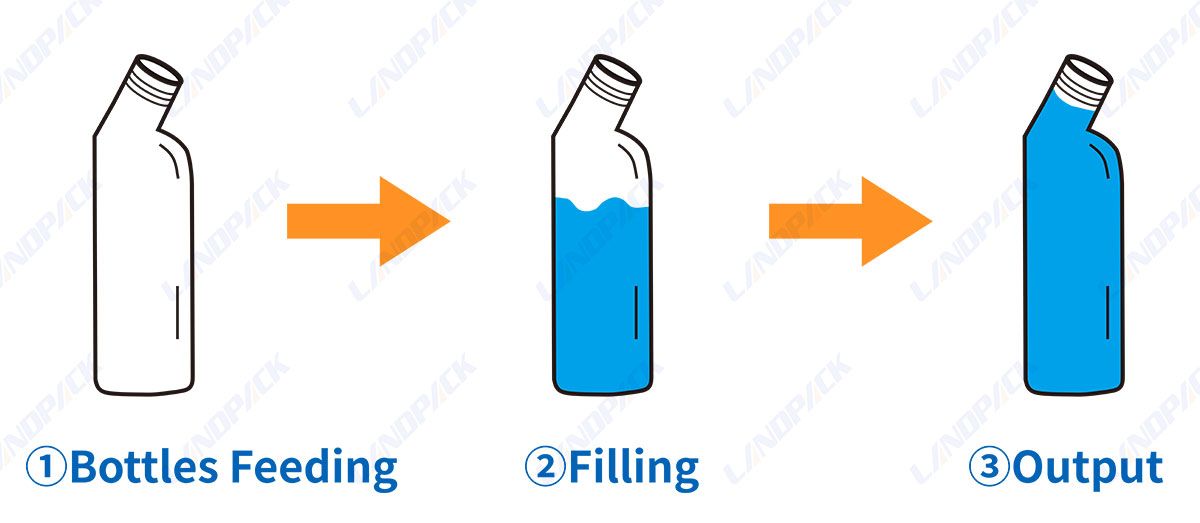

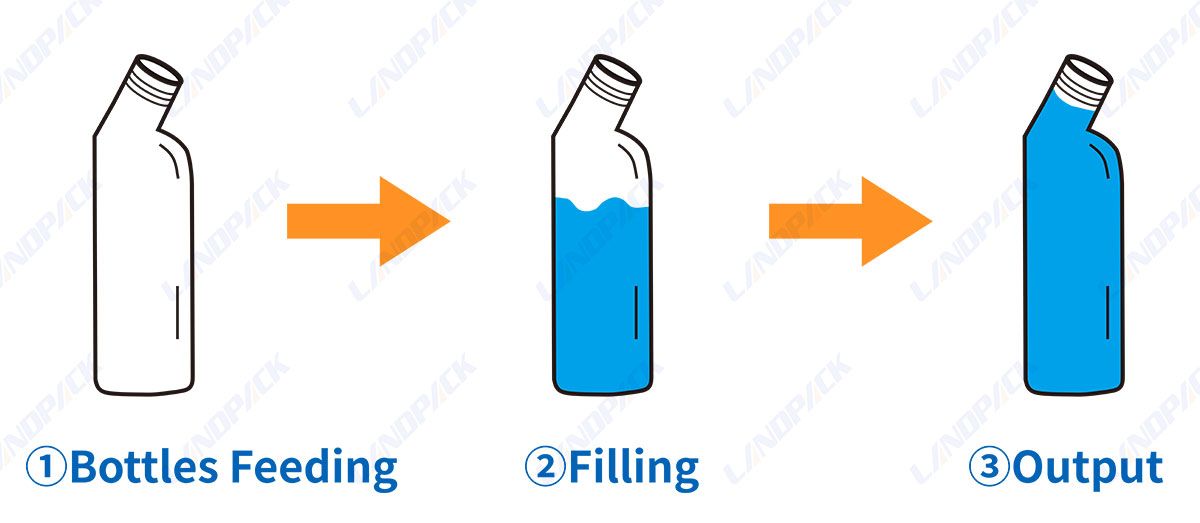

Workflow:

1. Bottles Feeding – Empty bottles are automatically fed into the line in an orderly and stable manner.

2. Filling – High-precision filling system accurately dispenses liquid or gel into each bottle.

3. Output – Finished bottles are smoothly conveyed out, ready for the next processing or packaging step.