Application:

This hardware visual counting packing machine is designed to integrate automatic visual counting, filling, and sealing to ensure accurate quantity control and consistent packaging quality. The system is widely used as a professional hardware packaging machine in industries such as hardware manufacturing, furniture fittings, electrical accessories, and construction components. With a working speed of up to 50 bags/min, it is ideal for manufacturers seeking efficient, accurate, and automated fastener packaging solutions.

Package Type:

This hardware visual counting packing machine supports multiple flexible packaging formats for accurate counting and sealing of small parts. Such as plastic bags, PE/PP bags, laminated bags, pillow bags, flat bags, etc.

Suitable Products:

This hardware visual counting packing machine is suitable for accurate visual counting and packaging of a wide range of small plastic and metal parts. Designed as a reliable fastener packing machine, it ensures precise quantity control, stable operation, and consistent packaging quality across multiple industries.

- Plastic & Metal Parts: Fasteners, Small hardware, Washers, Plastic Connectors

- Furniture Hardware: Small connectors Cable clips Torpedo level Plastic parts

- Others: Pharmaceutical Items, Snack, Electronic components, Building blocks

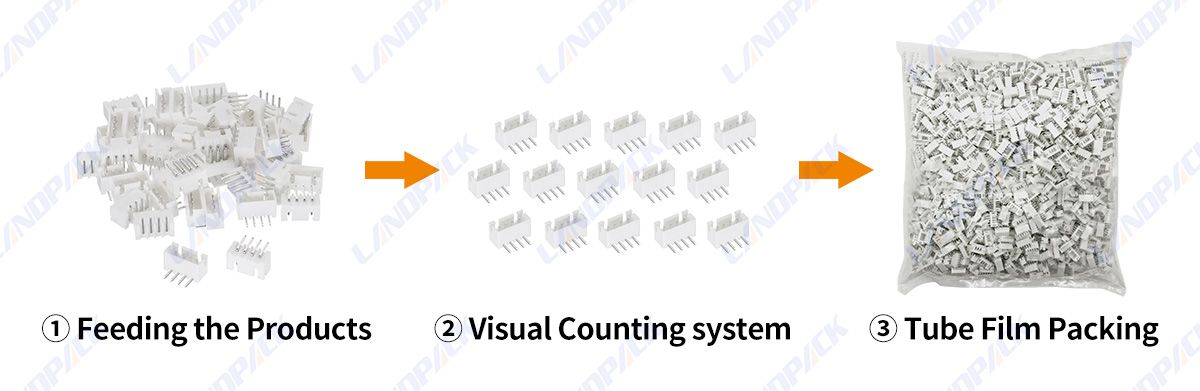

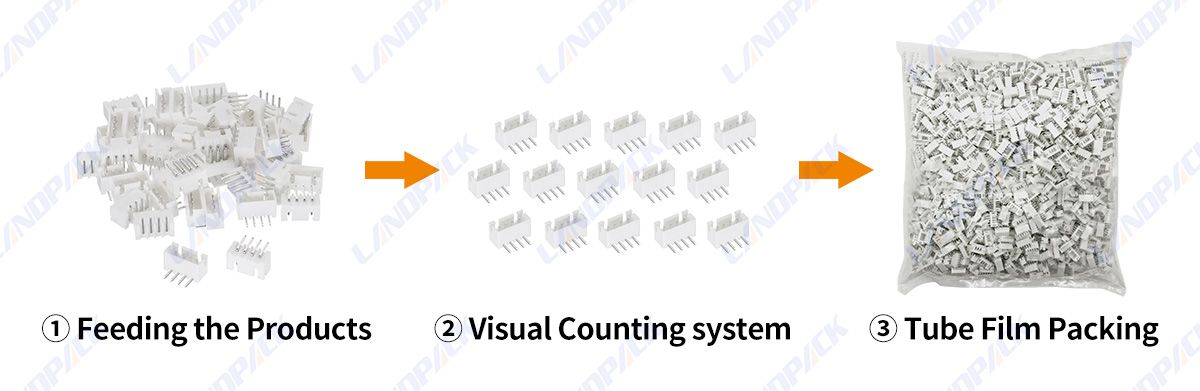

Workflow:

1. Material Feeding: Automatically feeding hardware or fasteners into the system.

2. Products Visual Counting: Counted fastener products accurately for each package

3. Products Filling: Filling fastener products into bags

4. Tube Film Filling & Sealing: Tube Film forming filling, and sealing

5. Output: Finished packages are discharged for collection or the next step.