Application:

High-speed rotary pouch packing machine for premade pouch packaging, handling premade pouches with precision and efficiency. Widely used in food, snacks, pet food, frozen products, daily chemicals, and pharmaceutical industries, with speeds up to 60 bags/min.

Package Type:

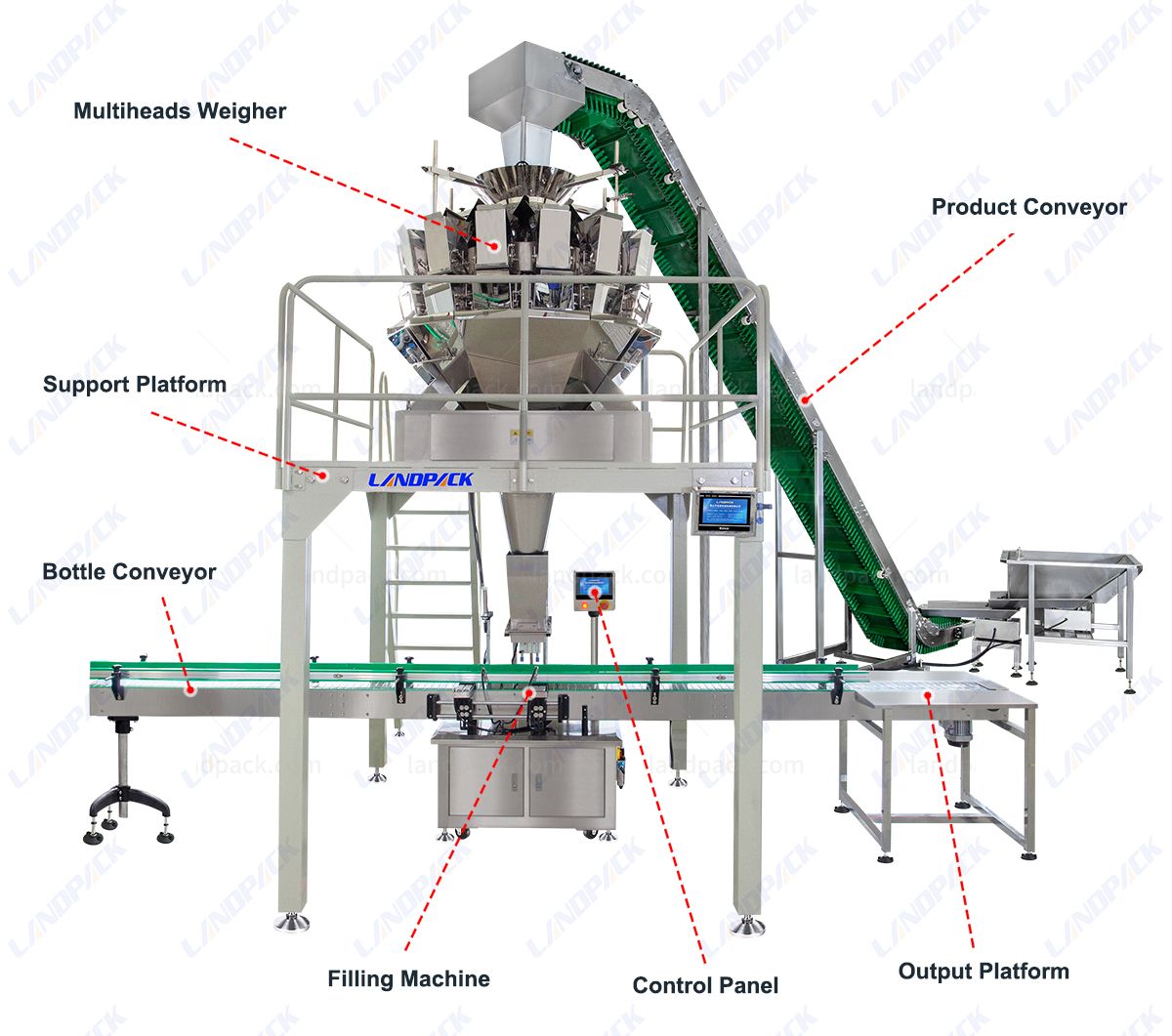

This automatic weighing and packing machine is designed to handle a wide range of boxes and containers, offering flexible solutions for different screw and hardware kit packaging needs.

It supports:

Plastic Boxes: Transparent or colored storage boxes for hardware assortments.

Cardboard Boxes: Standard folding cartons or corrugated boxes for bulk or retail packaging.

Small Cartons: Compact retail boxes for screw and fastener sets.

Compartment Boxes: Divided boxes ideal for mixed fastener or component assortments.

With its adjustable box conveyor and customizable filling nozzles, the system ensures precise filling and reliable performance across various box sizes and shapes.

Suitable Products:

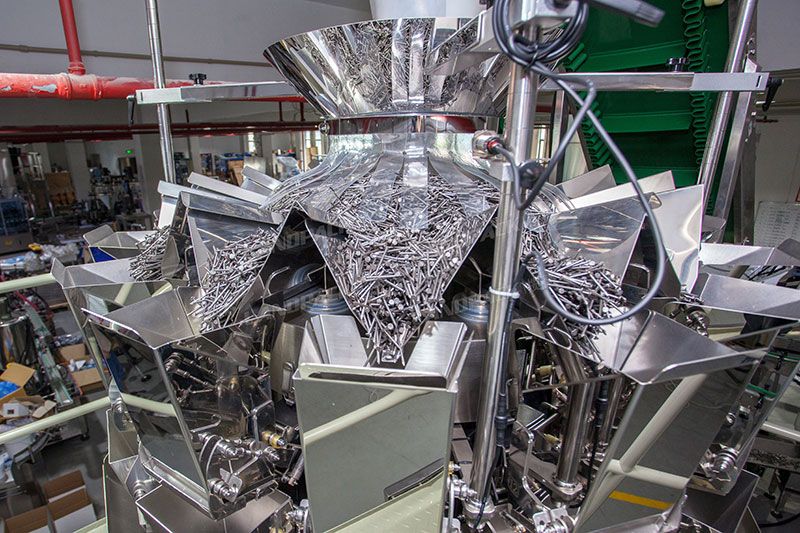

The Automatic Fastener Weighing Packing Machine Box Filling Machine is suitable for packing a wide variety of hardware fasteners, furniture accessories, and small components into boxes with accurate weighing and clean filling.

It is widely used for:

1. Fastener: Nails, Screws, Nuts & Bolts, Washers

2. Furniture Hardware: Small Connectors, Cable Clips, Torpedo Levels, Hinge Accessories

3. Other Hardware Components: Furniture Fittings, Plastic Connectors, Plastic & Metal Parts, Building Blocks

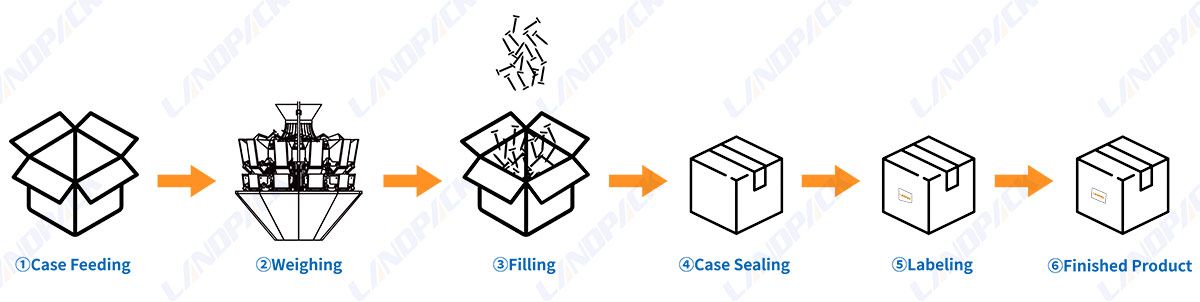

Workflow:

1. Case Feeding: Empty boxes are automatically conveyed to the filling station, ensuring smooth and continuous loading.

2. Weighing: The multihead weigher precisely measures the required quantity or weight of screws, guaranteeing consistent accuracy in every package.

3. Filling: Measured screws are evenly distributed into each box, minimizing waste and maintaining clean, organized packaging.

4. Finished Product: Filled boxes are automatically transferred to the output conveyor, ready for further packaging, sealing, or shipment.