Application:

The 50 bag/min counting and packing machine for hardware fittings is designed to count accurately and quickly package various fastener items. This machine is perfect for screws, nuts, washers and small hardware components in the hardware manufacturing, furniture accessories and electronic parts industries. The machine provides precise quantity control and stable performance. It also offers a variety of bag styles that can be customized to meet different production requirements.

Package Type:

Compatible with multiple bag formats commonly used in hardware packaging such as back sealing bags, pillow bags, gusset bags, flat pouches, small component sachets, custom-printed PE/PP laminated bags

Suitable Products:

This hardware fittings counting packing machine is suitable for a wide range of small components, including:

- Nails & Screws: Nails, Bolts, Washers, Screws

- Furniture Hardware: Small connectors, Cable clips, Torpedo levels, Hinge accessories

- Other Components: Furniture fittings, Plastic connectors, Plastic & metal parts, Building blocks

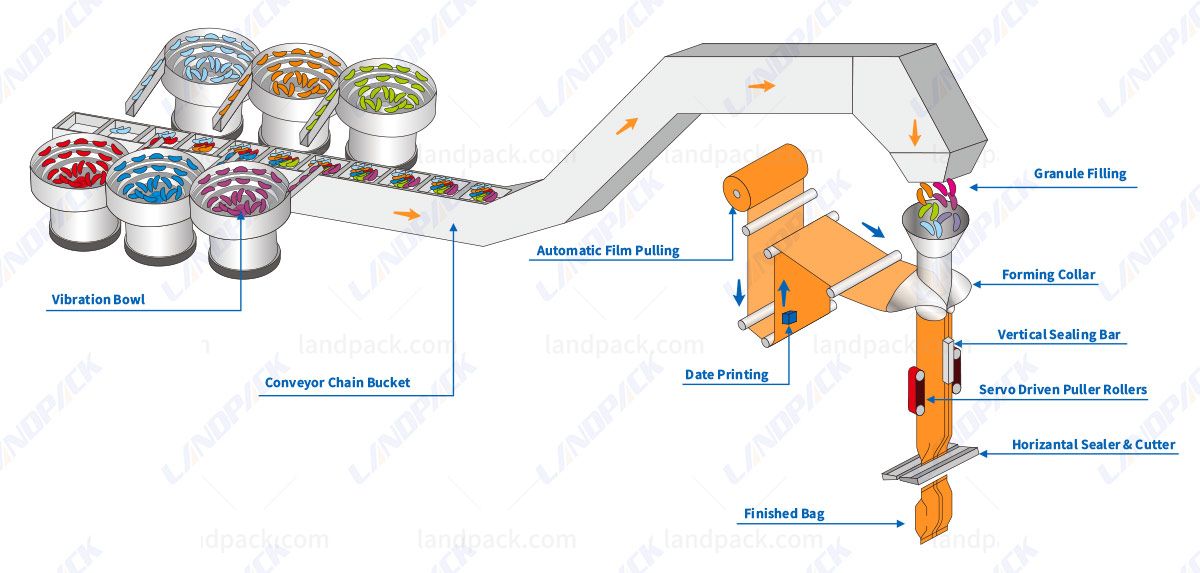

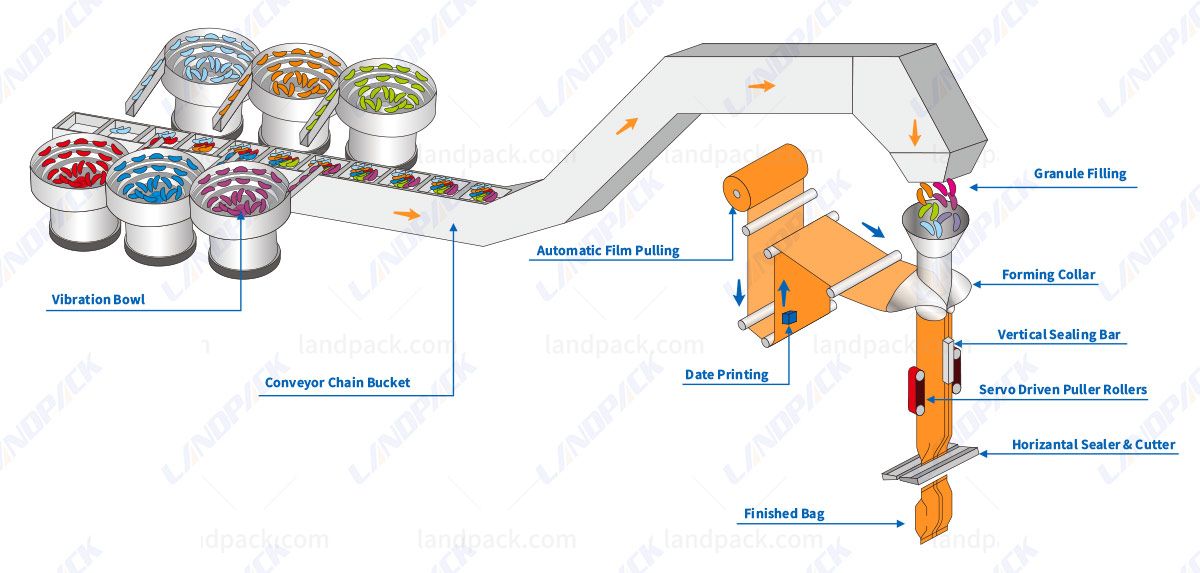

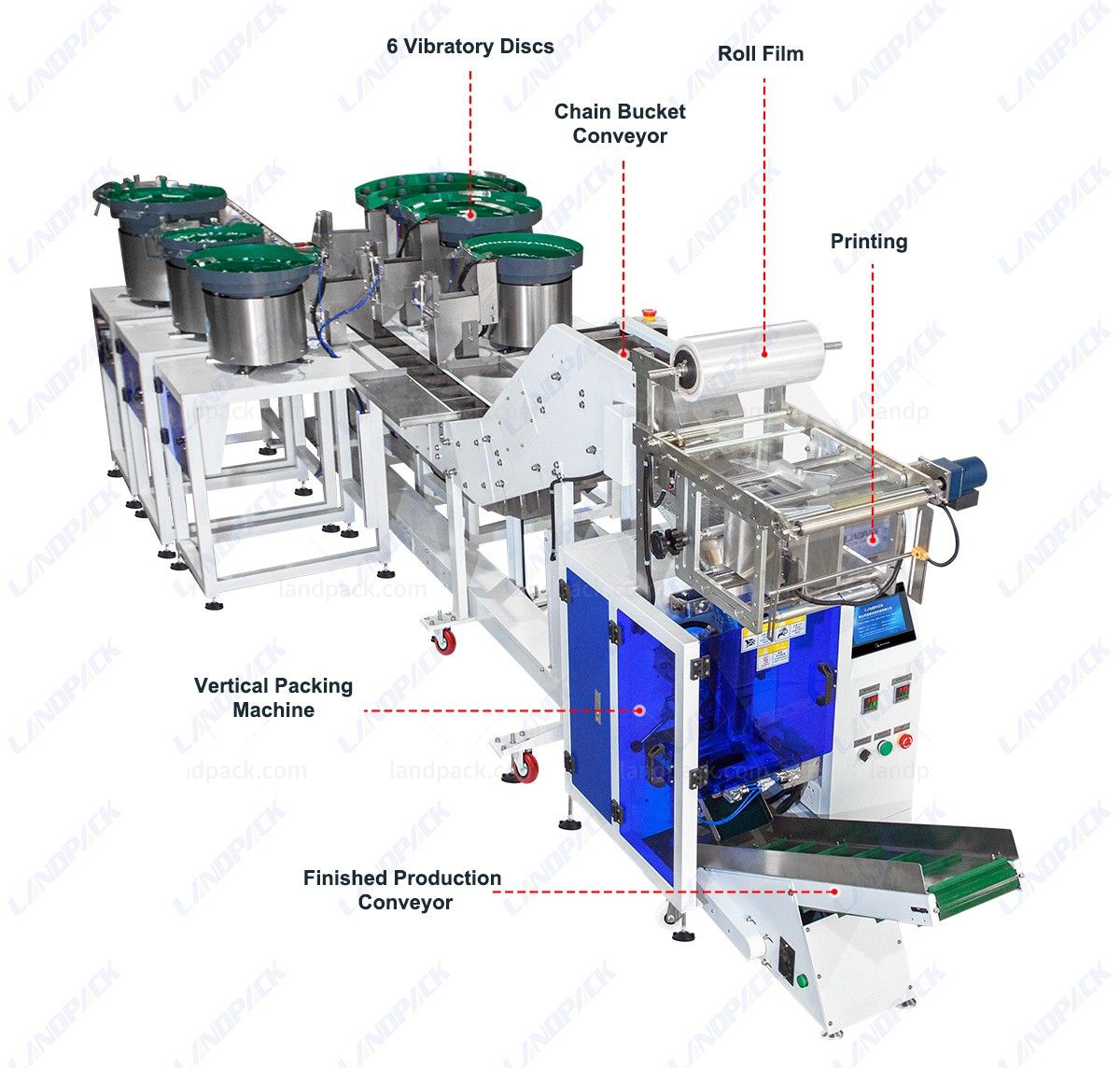

Workflow:

1. Vibration Bowl Feeding – Automatically orients and sorts fasteners.

2. Chain Bucket Conveying – Transfers and allocates items accurately.

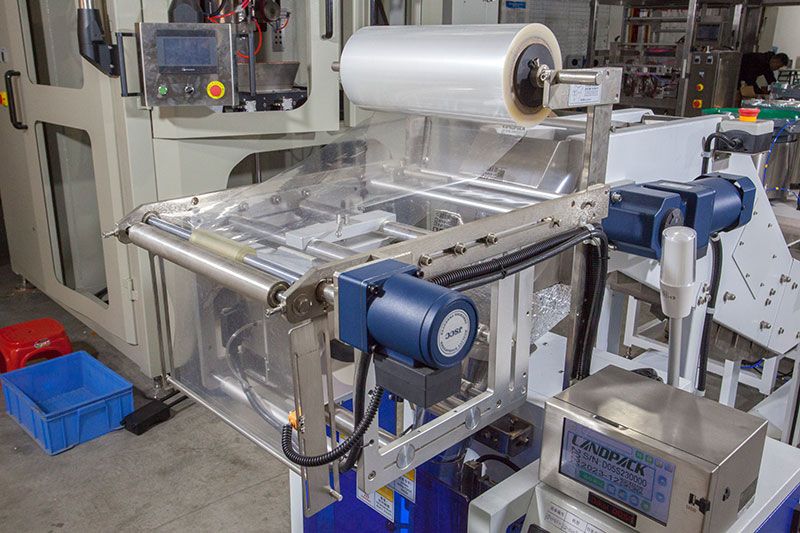

3. Automatic Film Pulling – Packaging film is pulled into the forming area.

4. Date Printing – Prints date or batch code on the film.

5. Granule Filling – Counted fasteners are dispensed into the forming tube.

6. Forming Collar – Film is shaped into a pouch.

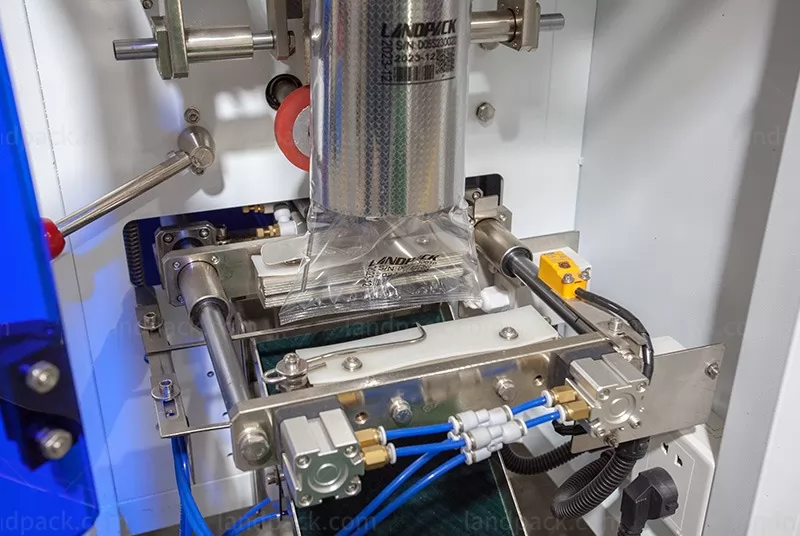

7. Vertical Sealing – Creates the back seal of the sachet.

8. Servo Puller Rollers – Ensures stable film pulling and consistent pouch length.

9. Horizontal Sealing & Cutting – Top/bottom sealing and cutting into individual bags.

10. Finished Bag Discharge – Final bags are delivered to the output conveyor.