Application:

Our automatic gummy filling machine line is designed for versatile gummy candy production, perfectly handling a wide range of gummy types, including gummy bears, vitamin gummies, jelly candies, and fruit-flavored gummies. The line ensures consistent quality and precise dosing across different shapes and sizes, making it ideal for diverse production needs. With a production capacity of up to 30 bottles/min, this machine line meets the demands of medium to large-scale factories, delivering high efficiency without compromising accuracy or hygiene.

Package Type:

The Landpack gummy filling machine line is designed for flexible container compatibility, easily handling both bottles and buckets. Whether you are packaging small individual gummy bottles for retail or larger buckets for bulk distribution, the machine ensures precise filling, consistent weight, and secure sealing for each container.

Suitable Products:

Suitable for a wide range of gummy candy materials, including gelatin-based gummies, pectin gummies, vitamin-infused gummies, jelly candies, fruit-flavored gummies, functional nutraceutical gummies and other granule materials. This gummy filling machine line ensures precise dosing, uniform texture, and consistent quality across all types of gummy formulations.

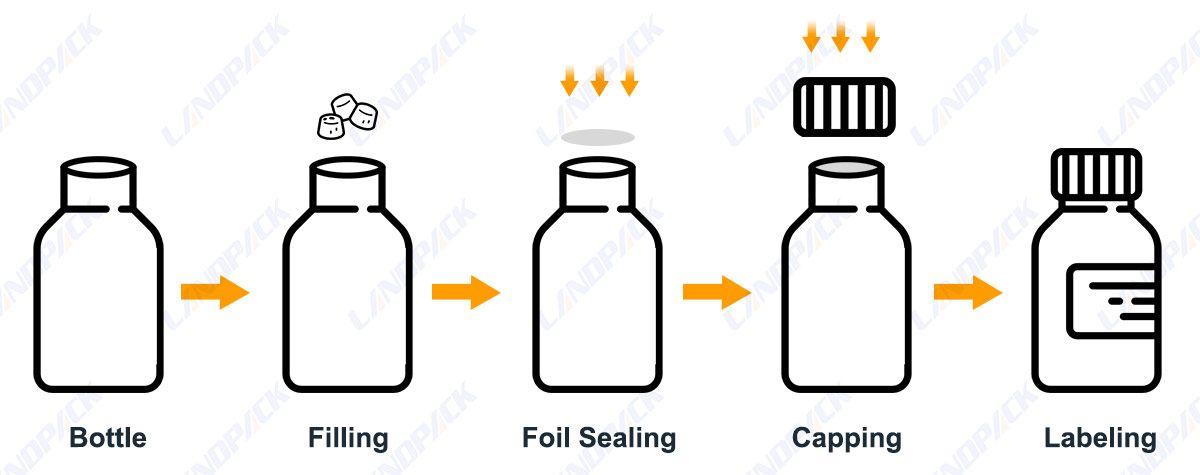

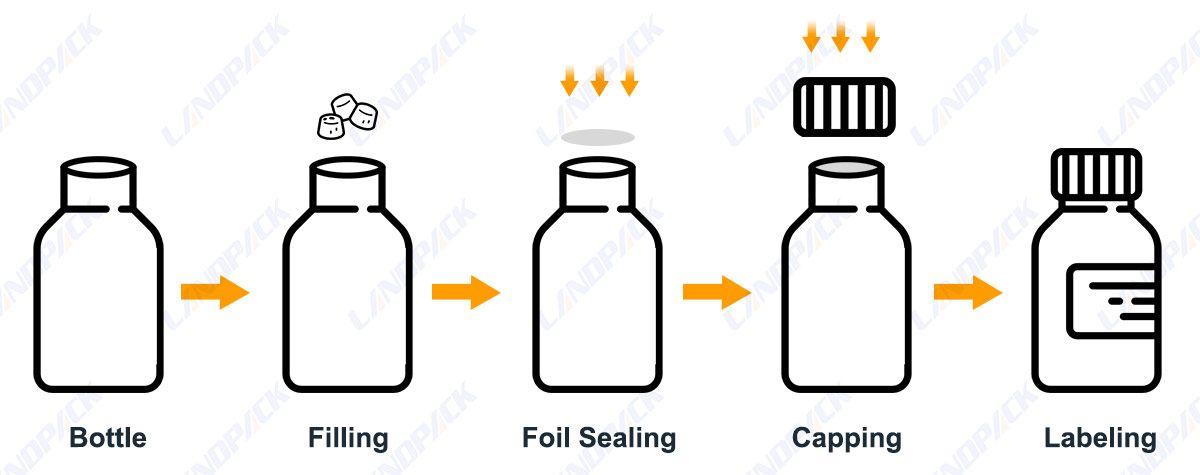

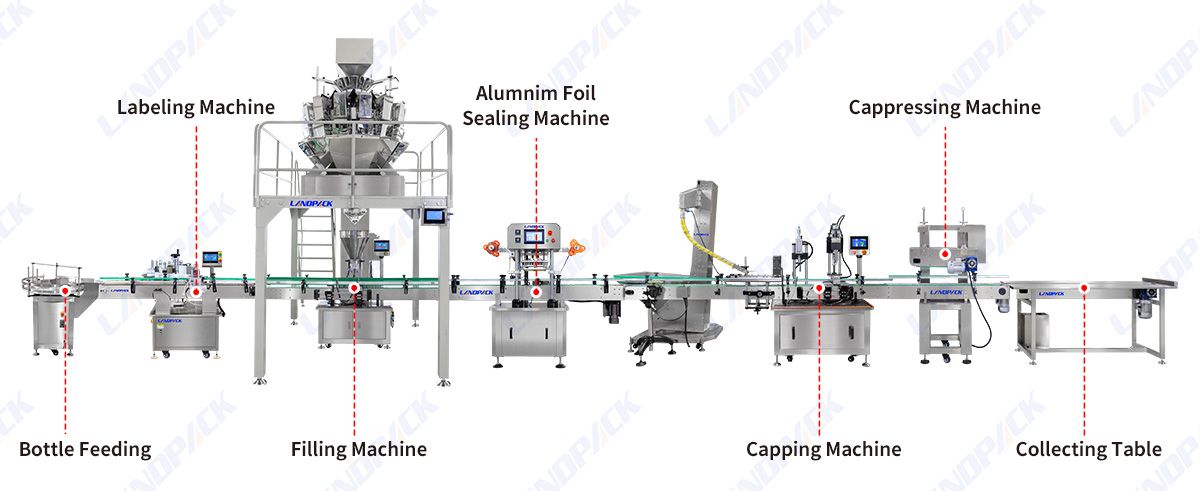

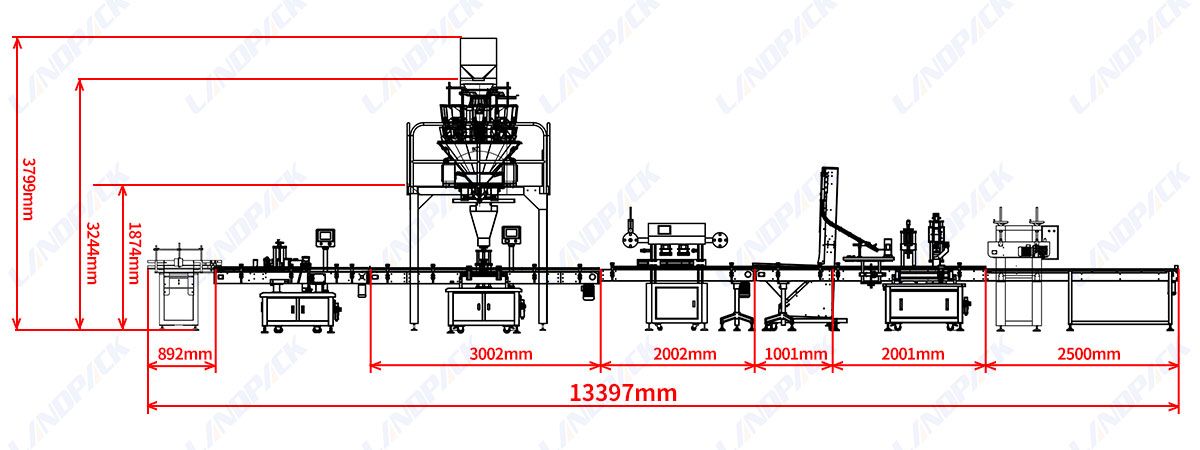

Workflow:

1. Bottle Feeding – Empty bottles are automatically fed into the production line, ensuring smooth and continuous operation.

2. Labeling – Labels are applied precisely on each bottle for a neat, professional appearance.

3. Weighing – Each bottle is accurately weighed to guarantee consistent product quantity and minimize waste.

4. Filling – The gummy filling machine precisely dispenses gummy candy into each bottle or container.

5. Aluminum Foil Sealing – Bottles are sealed with aluminum foil to keep the gummies fresh and prevent leakage.

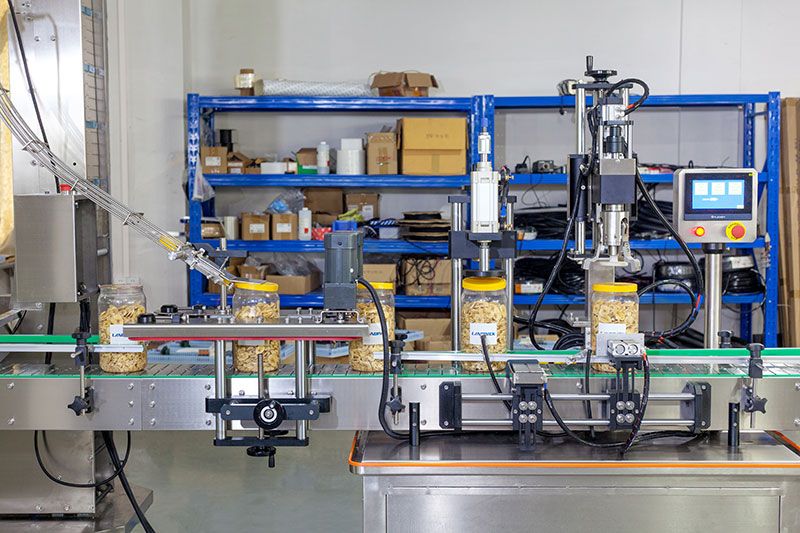

6. Capping – Caps are automatically placed or screwed onto bottles, ensuring secure closure.

7. Cap Pressing – The machine presses caps firmly in place for tight sealing and stable packaging.

8. Output Collecting – Finished bottles are collected neatly for easy inspection, packing, or shipment.