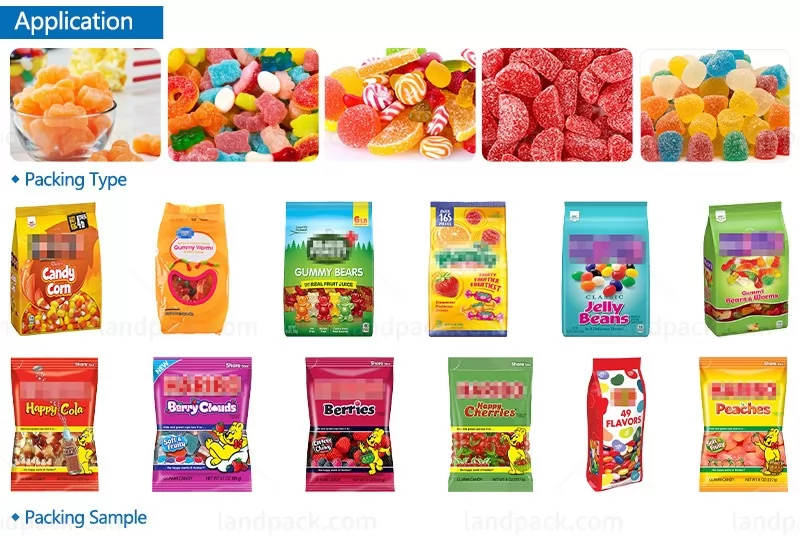

Wide Application Range:

The LD-420A Vertical Packaging Machine is designed for gummy and soft candy packaging, delivering high precision, stable operation, and excellent sealing performance. It efficiently handles a wide range of confectionery products with different shapes, textures, and coatings, ensuring clean sealing and attractive retail presentation.

Here are some common applications and product types suitable for this model:

Suitable Industry:

The sandwich biscuit pillow packaging machine is specially designed for cream-filled biscuits and cookies. Equipped with an automated cream injection system and a stacking device for two-layer arrangement, it ensures precise sandwiching and efficient packaging of products like chocolate biscuits, wafer cookies, and cream-filled crackers.

* Gummy Candies: Fruit-flavored gummies, vitamin gummies, jelly candies, soft chewies, and sugar-coated gummies

* Soft Candies & Caramels: Toffee, milk soft candy, chocolate chewies, and caramel cubes

* Jelly & Gel-Based Snacks: Mini jelly bites, collagen gummies, and healthy functional gummies

* Mixed & Customized Products: Assorted gummies with multiple flavors or colors, sugar-free or vitamin-enriched candies

Packaging Style:

This high-speed packing machine is suitable for packing back sealing bags, pillow bags with or without easy tear.

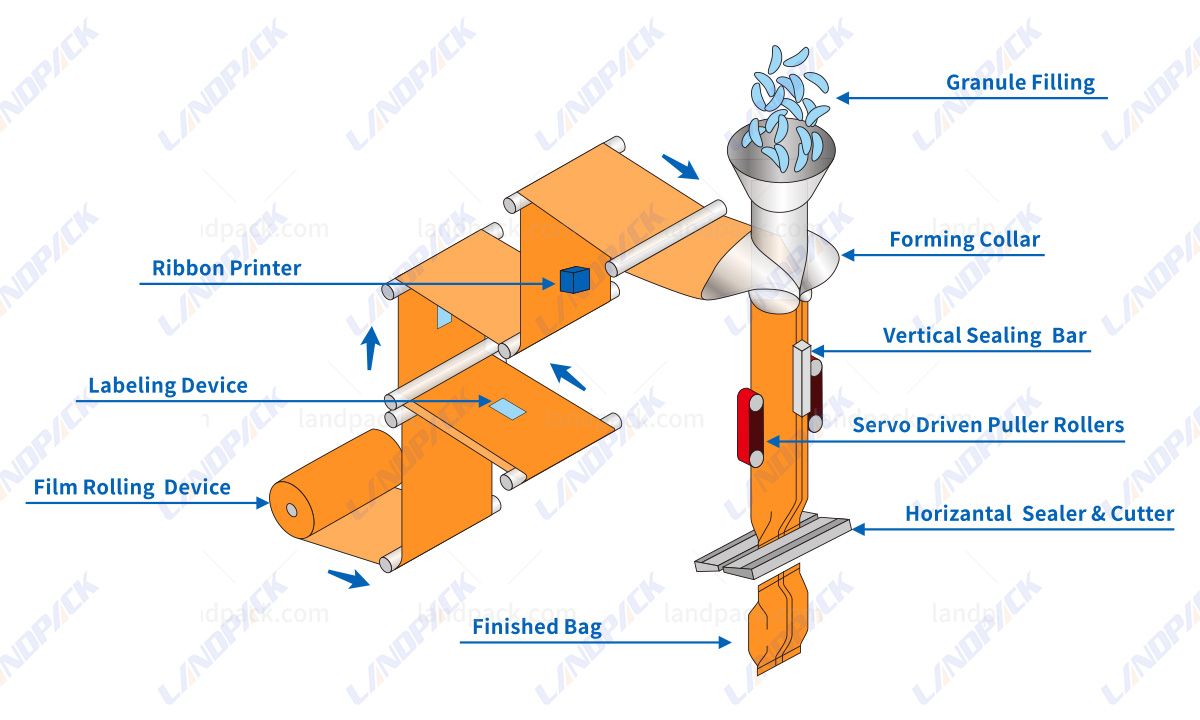

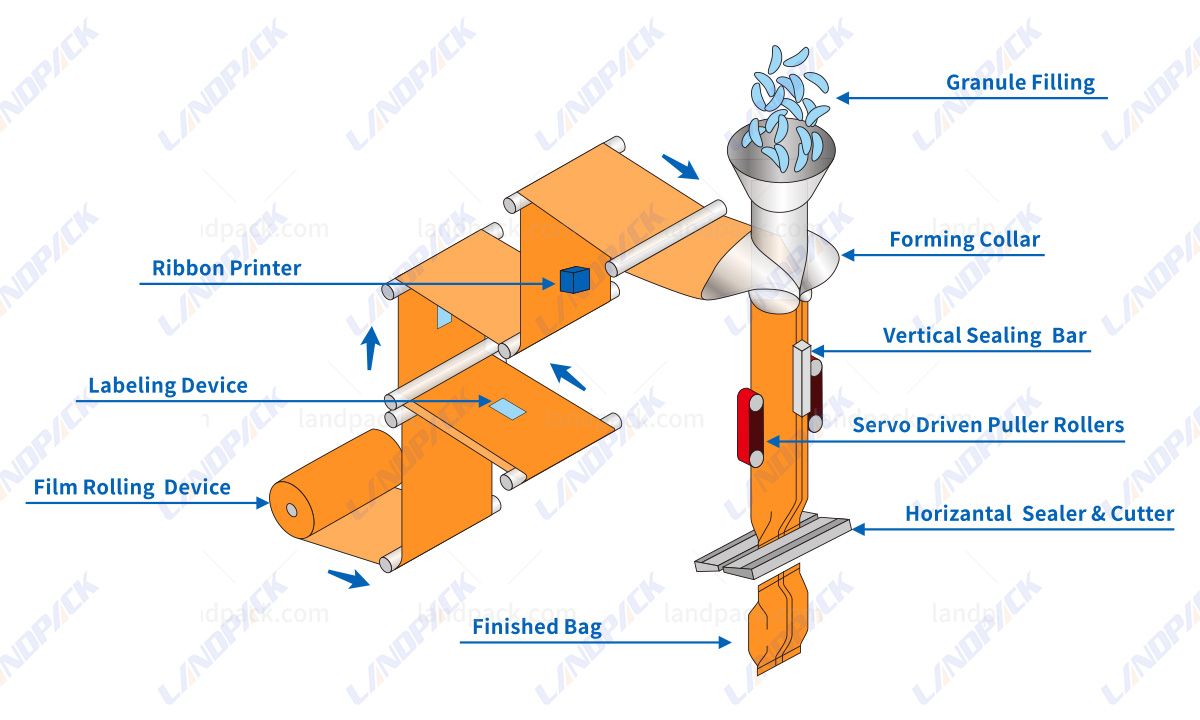

Gummy Vertical Packing Machine Production Process:

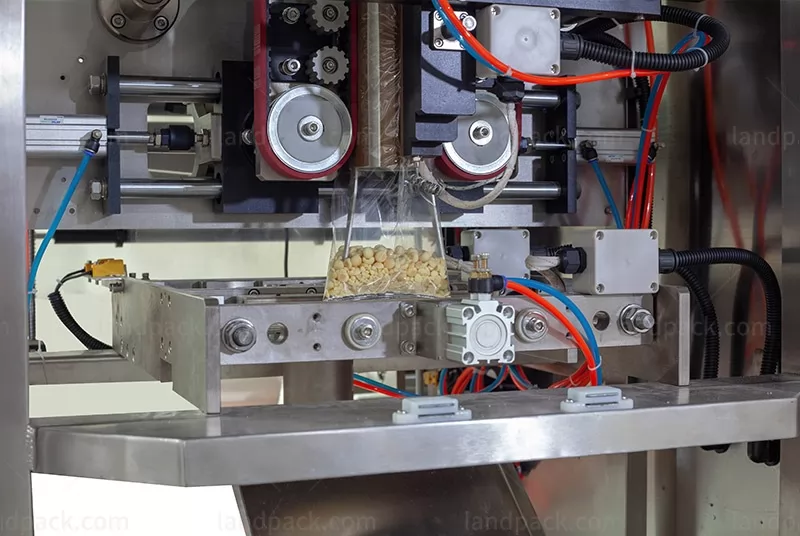

* Feeding & Weighing – Soft candies are gently delivered via a Z-type elevator or linear weigher, preventing product damage and sticking during feeding.

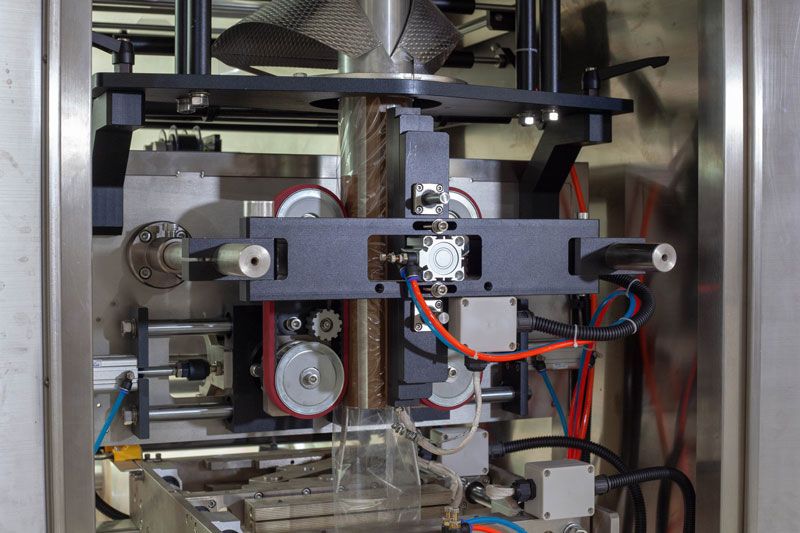

* Film Pulling & Bag Forming – Packaging film is automatically pulled down and shaped into a tubular form around the forming collar.

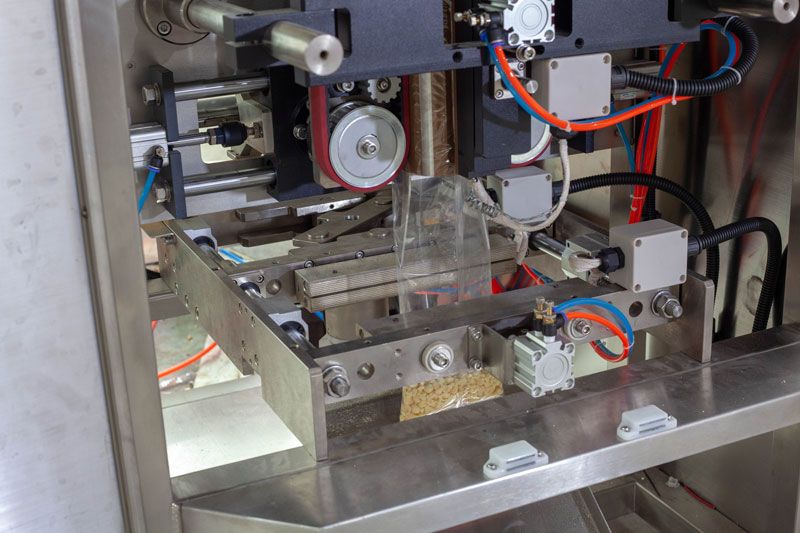

* Filling & Sealing – Weighed gummies drop into the formed bag; horizontal sealing jaws close and cut the bag precisely.

* Cutting & Discharge – Finished bags are cut into uniform sizes and smoothly discharged onto the conveyor belt, ready for secondary packing or cartoning.