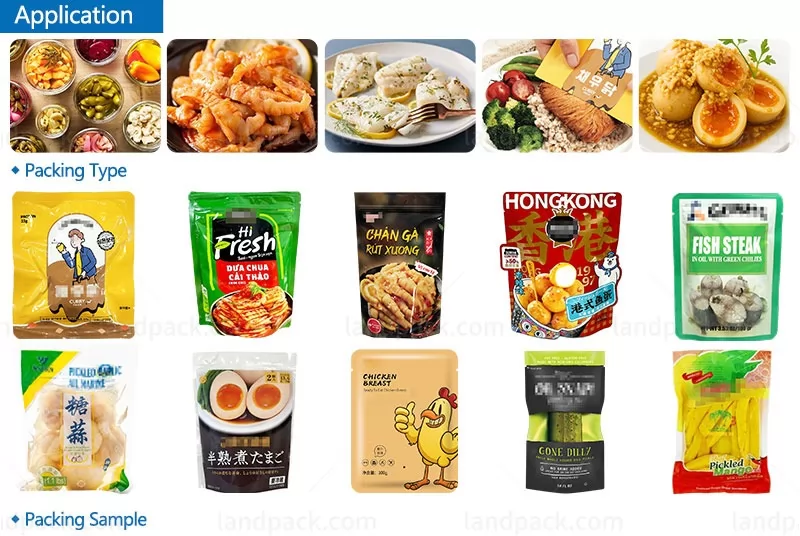

Application:

This duplex horizontal pouch packing machine is widely applied in industries requiring flexible packaging of both granules with liquids, such as kimchi, pickled vegetables, fish snacks, sauces, and other ready-to-eat foods. It is ideal for brands seeking high efficiency, precise filling, and consistent pouch presentation.

Suitable Products:

The High Speed Duplex Horizontal Pouch Packing Machine is specially designed for the flexible packaging of both granules with liquid-based products. It offers wide adaptability across different industries, ensuring high precision and efficiency. Typical applications include:

- Snacks & Ready Meals

Pickled cucumber, fruit mix, soft-boiled eggs, Thai-style chicken feet, Ready-to-eat side dishes and small portioned meal packs

- Meat & Seafood Products

Fish meat with sauce, chicken cubes with gravy, cooked beans with sauce, rice with curry, and marinated seafood

- Dairy & Dessert Fillings

Yogurt flavored with jams made from fruit custard cream mix of chocolate sauce suking pudding, jelly, and mousse desserts

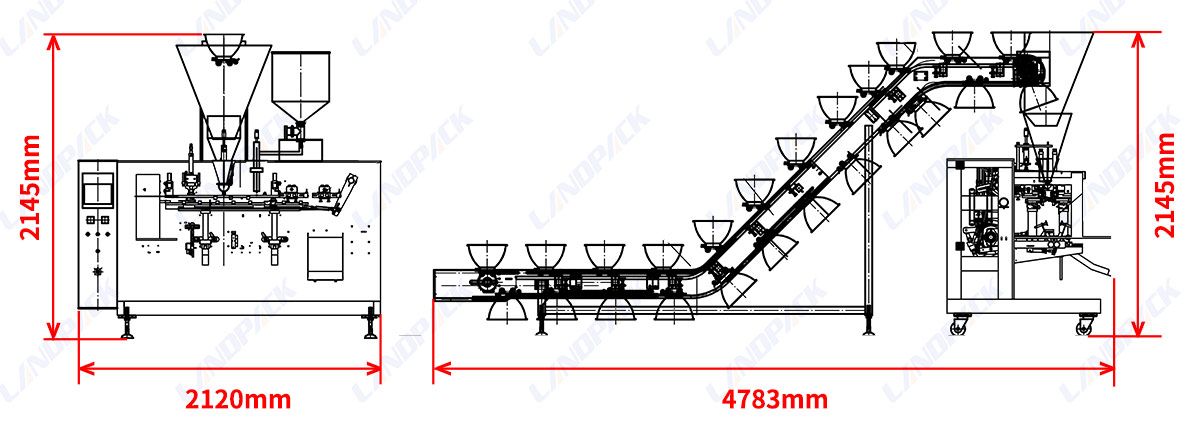

Thanks to its dual-lane design this machine will produce more bags per minute (up to 50 bags/min) while ensuring consistency in packaging which makes it a great option for food manufacturers who handle various items.

Package Type:

The double track horizontal pouch packing machine is compatible with a wide range of premade pouch types, including zip lock bags, stand-up pouches, M-shape gusset bags, and other customized pouch styles.

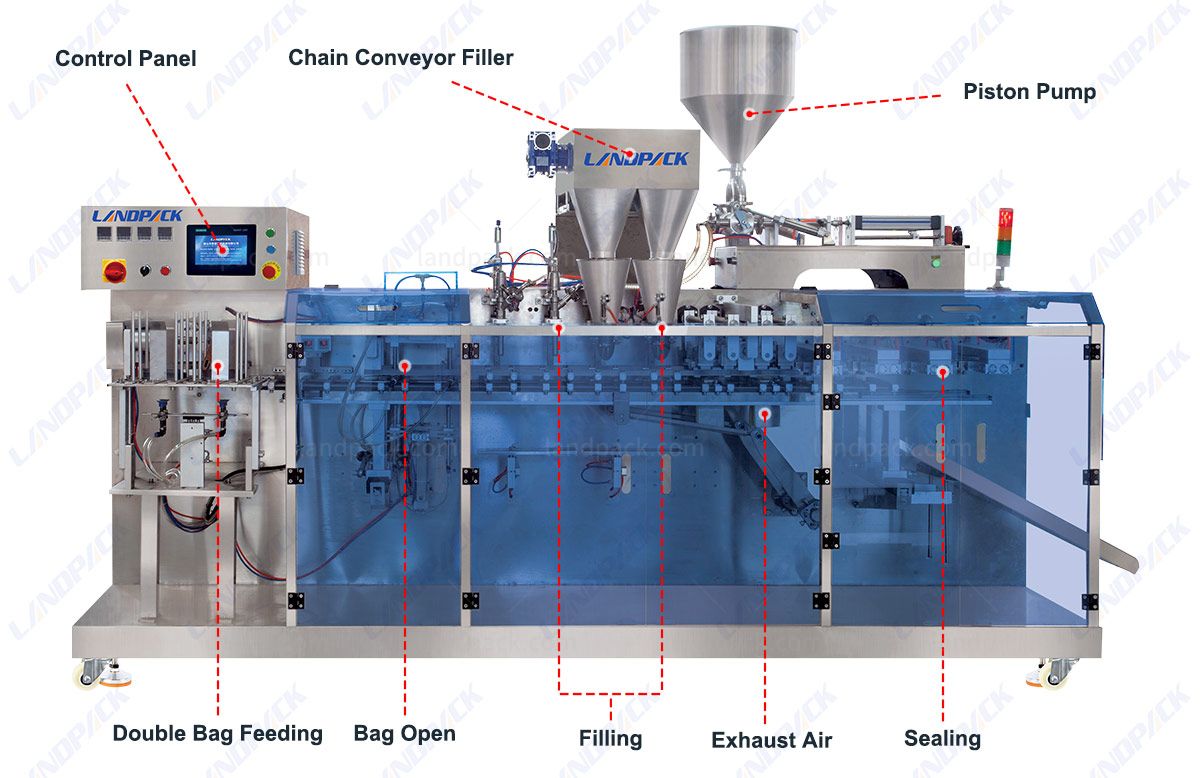

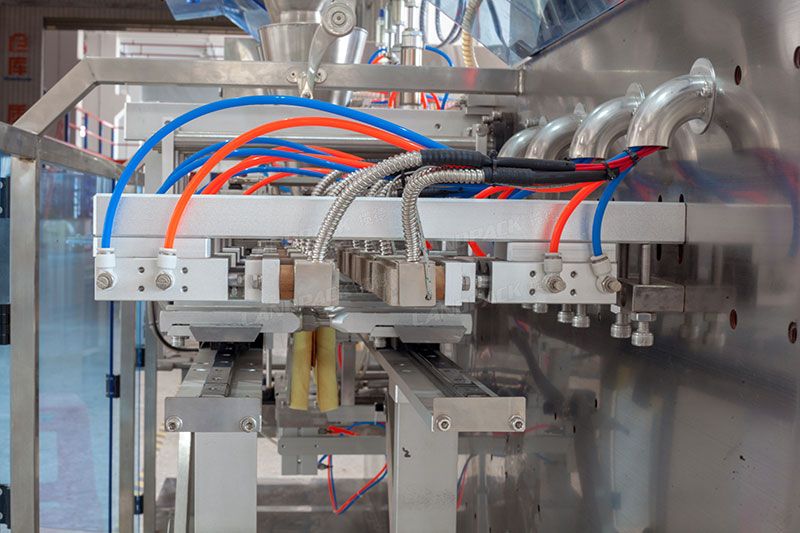

Workflow:

This is duplex horizontal pouch packing machine for granule with liquid products in premade pouches. Here's how it works step-by-step:

1. Double Bag Feeding – Two premade pouches are automatically fed into the machine at the same time.

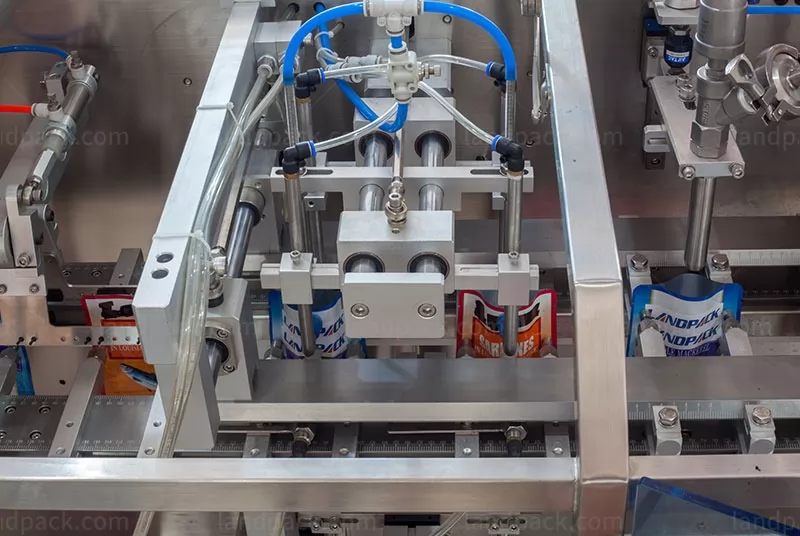

2. Double Bag Opening – The pouches are opened smoothly and prepared for filling.

3. Double Liquid Filling – Liquid products (such as sauces, soups, or gravies) are precisely packed into two pouches.

4. Double Snack Filling – Either solid or Granular items (like meat cubes, vegetables or beans) are packed in identical pouches.

5. Exhaust Air – Excess air inside the pouch is removed to keep the product compact and extend shelf life.

6. Double Bag Sealing – The filled pouches are sealed tightly to ensure freshness and prevent leakage.

7. Output – Bags are neatly discharged and ready to be used for secondary packaging or distribution directly.