Application:

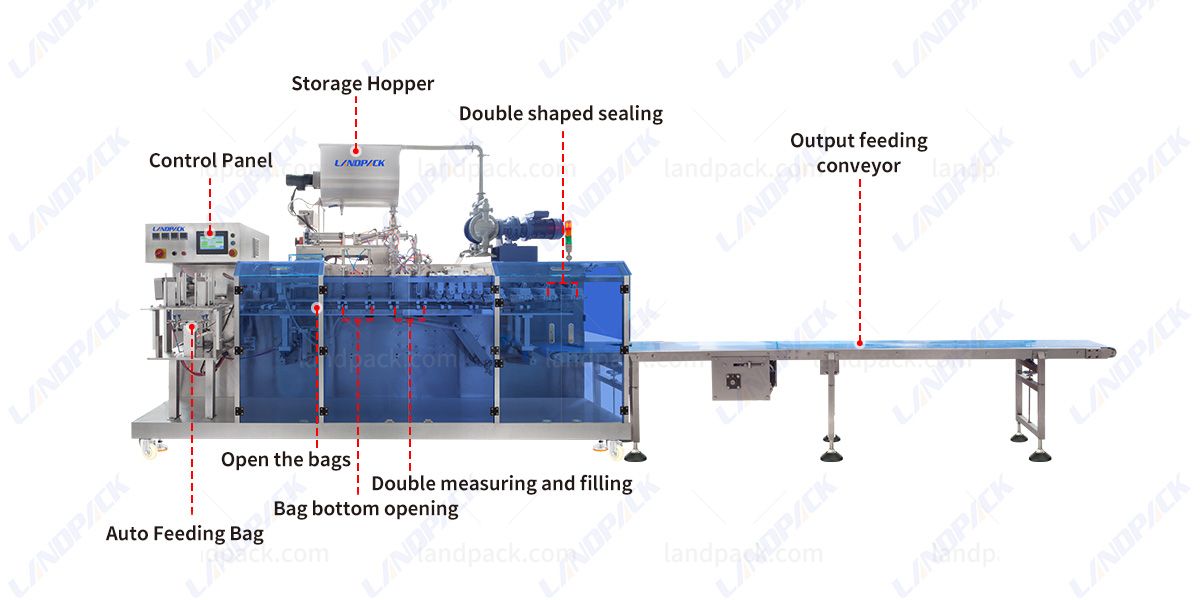

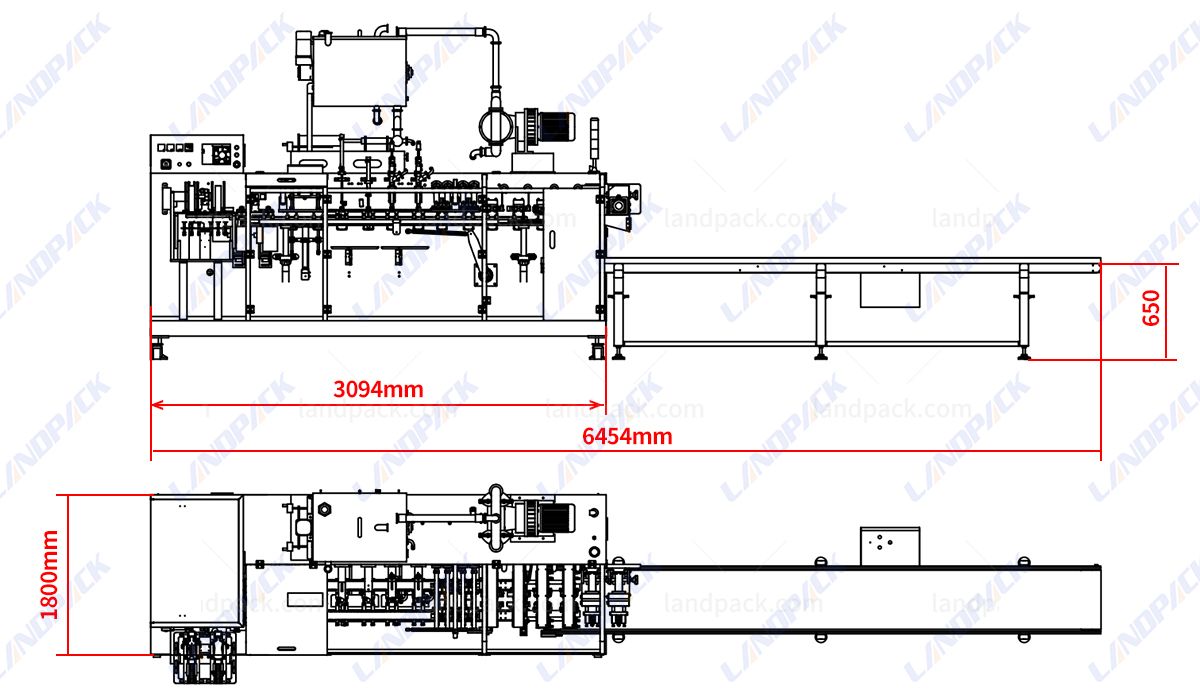

This duplex horizontal premade pouch packing machine can produce up to 160 bags/min of semi-viscous and viscous liquids. This machine is suitable for custom-shaped pouches, flat pouches as well as spouted pouches. It is widely used for juice, jellies, beverage concentrates and yogurts. Ideal for brands looking to create shaped pouches that look premium and have a consistent quality.

Package Type:

Engineered to handle a wide variety of premade pouch styles with stable operation and high sealing quality. such as stand-up pouch, flat pouch / 3-side seal pouch, shape pouch / bottle-shaped pouch, spout pouch, zipper pouch, quad seal/gusset pouch.

Suitable Products:

This machine can be used in a variety of industries because it is suitable for liquids and semi-liquids.

- Nutritional & Health Products: Energy gels, protein drinks, vitamin liquids, oral liquid supplements.

- Beverage industry: Juice, yogurt, flavored beverages, beverage concentrates.

- Daily Care & Cosmetic Liquids: Shampoo, conditioners, lotions, liquid soaps, cleansing gels.

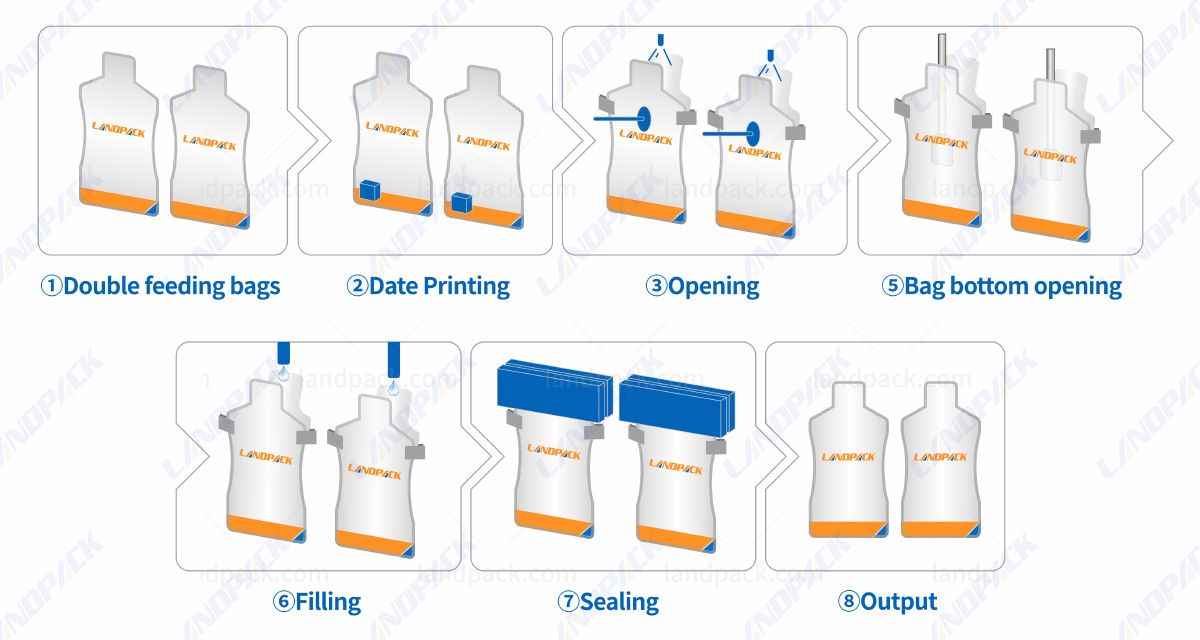

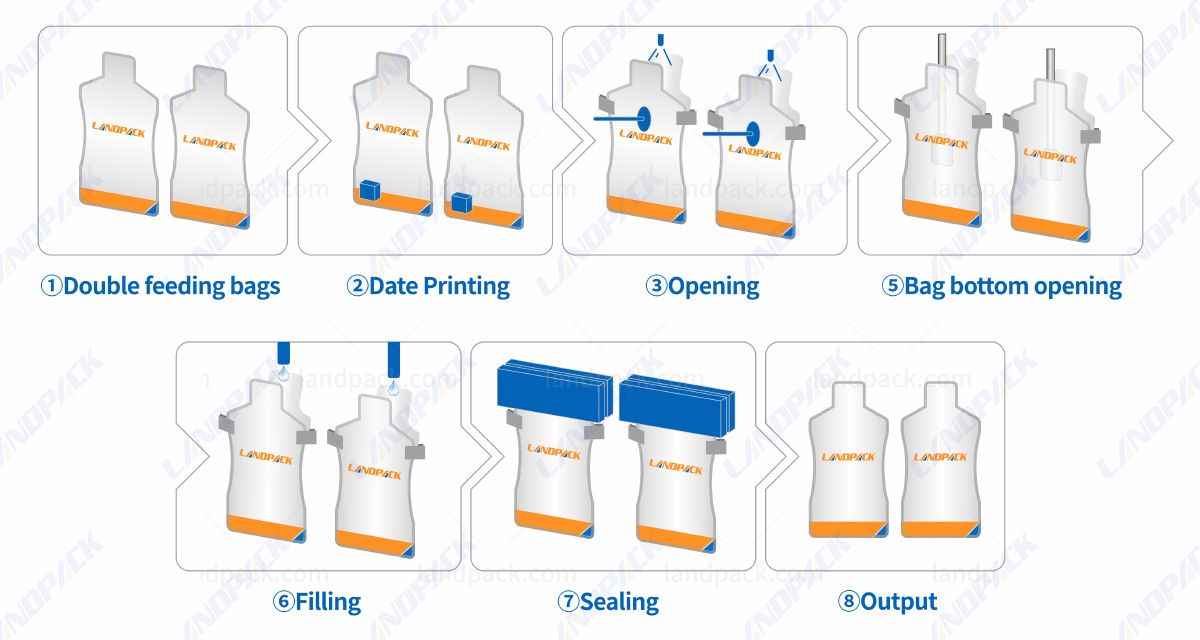

Workflow:

This is duplex horizontal premade pouch packing machine for liquid products in premade pouches. Here's how it works step-by-step:

1. Double Bag Feeding – Two premade pouches are automatically picked and fed simultaneously for high-speed production.

2. Date Printing – Expiry date, batch code, or production info is printed accurately on each pouch.

3. Bag Opening – Suction pads open the top of the pouch smoothly and reliably.

4. Bottom Opening – Ensures the pouch is fully expanded for clean and accurate filling.

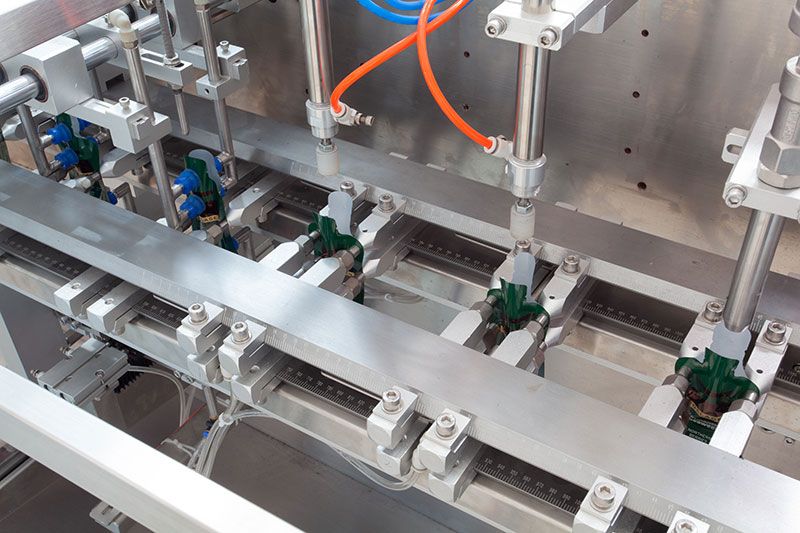

5. Filling- Products that are liquid or semi-liquid are precisely dispensed into each pouch.

6. Sealing- Heat sealing creates a leak-proof, strong closure.

7. Output- The finished pouches are discharged onto the conveyor neatly for collection or downstream packaging.