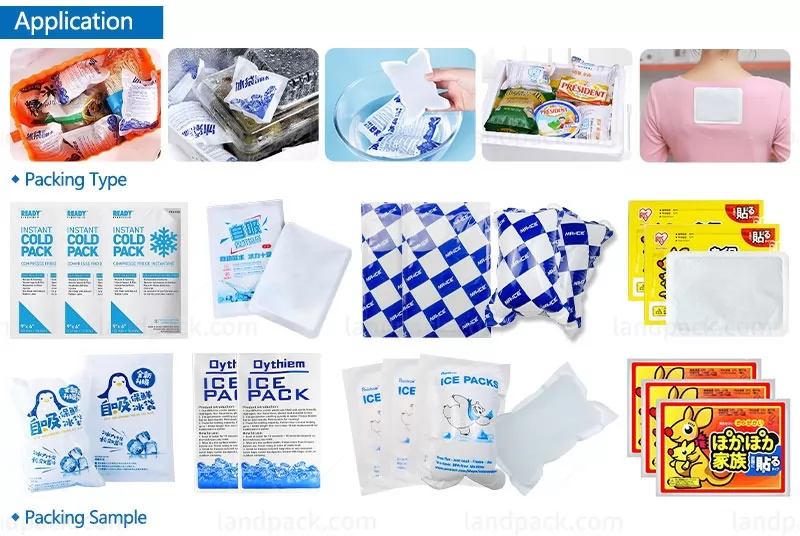

Application:

Its synchronized film tracking and stable heat‑seal system create strong, leak‑proof packages that protect contents and enhance product presentation.

Package Type:

This ice pack four-side seal packaging machine is designed for flat, pillow-style four-side sealed pouches made from laminated films.

It supports PET/PE, PET/CPP, PET/AL/PE, and medical-grade composite films, delivering fully enclosed, leak-proof packages with clean edges. The finished packs offer strong sealing integrity, uniform shape, and reliable protection for liquid, gel, or sheet products.

Suitable Products:

This four‑side seal packaging machine handles a variety of sheet, flexible, and flat products that require sealed pouches on all four sides. Suitable materials include:

Medical & Personal Care Items: Ice packs, cooling gel packs, face masks, cosmetic sheet masks, medical dressings and adhesive patches.

Cosmetics & Healthcare Sheets: Facial masks, ointment patches, cooling patches, skincare sheets, and therapeutic wraps.

Daily & Miscellaneous Items: Disposable masks, non‑woven fabrics, small accessories, wipes, and similar products needing protective four‑side sealed bags.

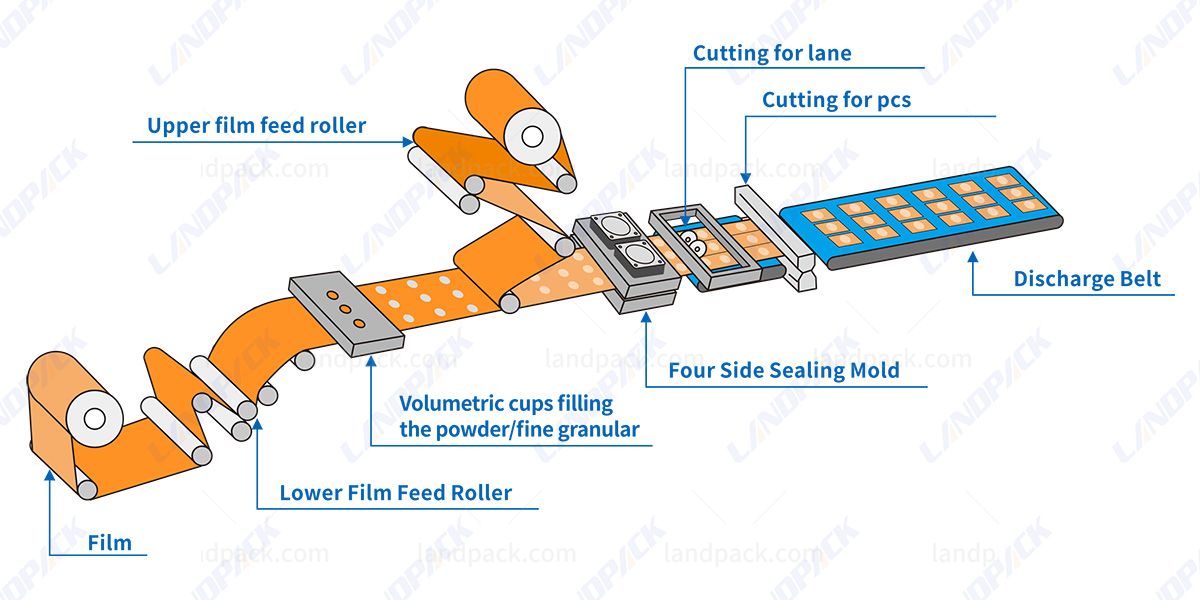

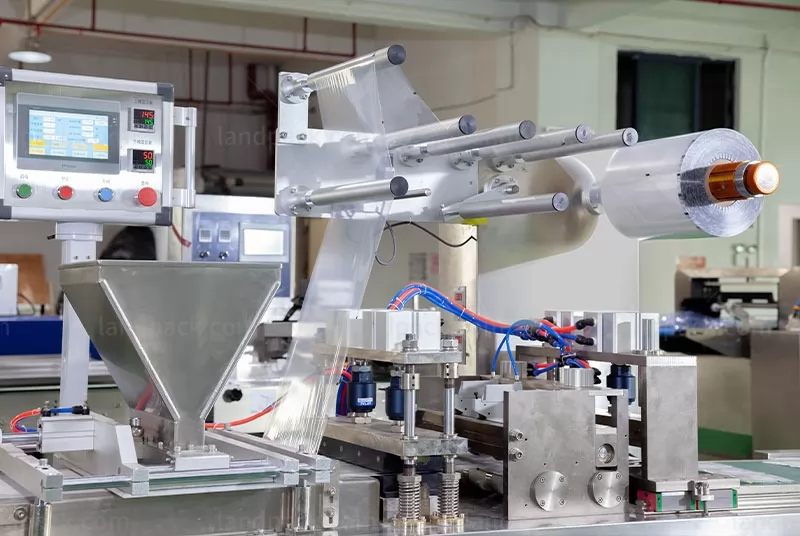

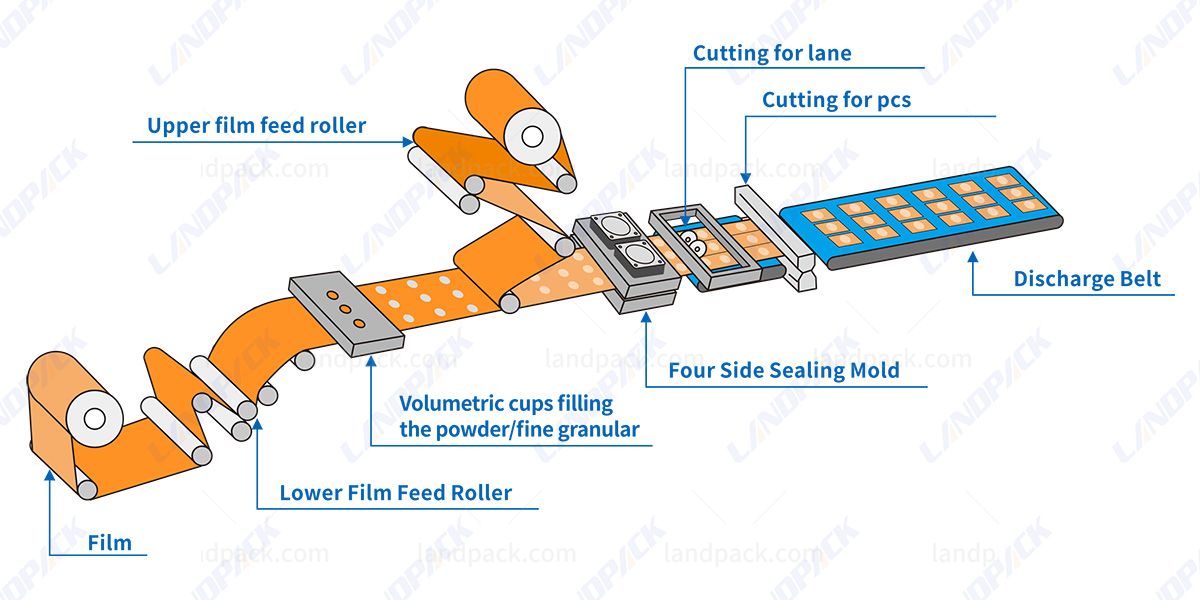

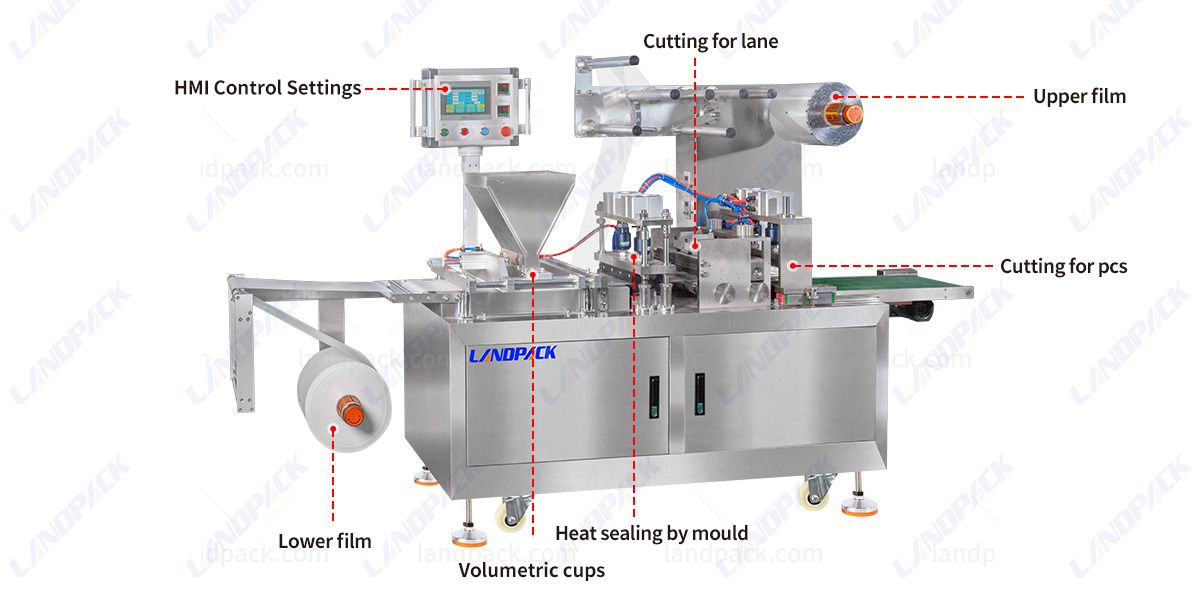

Workflow:

1. Material Feeding

2. Date Printing

3. Measuring and Filling

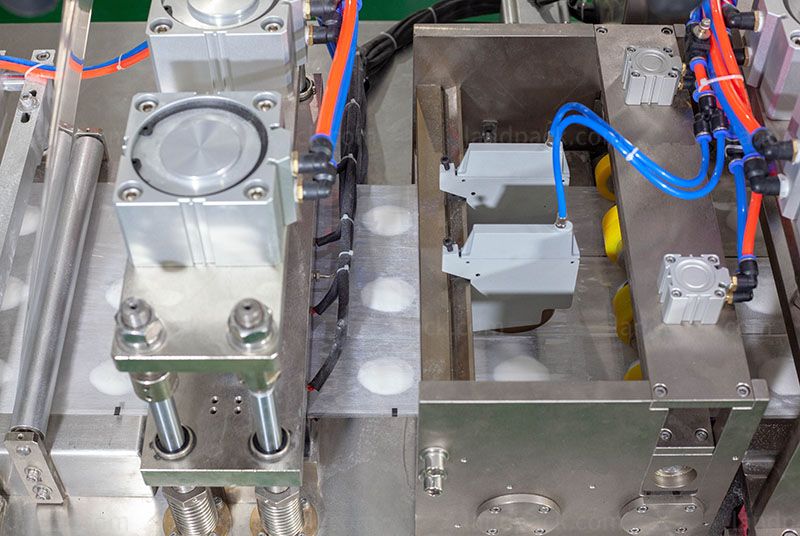

4. Four Sides Sealing

5. Cutting

6. Output