Application:

The LD-720AS Vertical Weighing Packaging Machine is designed for efficiently packing a wide range of free-flowing or slightly sticky products. It is ideal for ice cubes, frozen fruits, vegetables, and seafood, as well as large granular items such as sugar, salt, coffee beans, pet food, and small snacks.

Package Type:

The LD-720AS is designed for pillow bags, gusseted bags, and back sealing pouches, providing flexible packaging styles for different product sizes. It supports single or multiple weight packs according to production needs. The finished bags are strong, neat, and airtight, ensuring excellent protection for ice cubes or granular products.

Wide Application Range:

The LD-720AS Vertical Weighing Packaging Machine is a high-performance model designed for packing heavy, irregular, or wet products such as ice cubes and frozen foods. Built with a durable stainless-steel structure and waterproof design, it ensures reliable performance in cold or humid environments. Equipped with a precision multi-head weigher and servo-driven film system, it delivers stable operation, accurate weighing, and strong sealing for extended product freshness.

This machine is widely used in the frozen food and cold-chain packaging industries, offering a versatile solution for a wide range of granular or block-type products, including:

Ice Products: Such as cube ice, crushed ice, and tube ice

Frozen Fruits & Vegetables: Diced mango, pineapple, mixed berries, peas, and corn

Seafood Products: Shrimp, scallops, small fish, squid rings, and other frozen seafood

Frozen Prepared Foods: Dumplings, meatballs, and other ready-to-cook frozen products

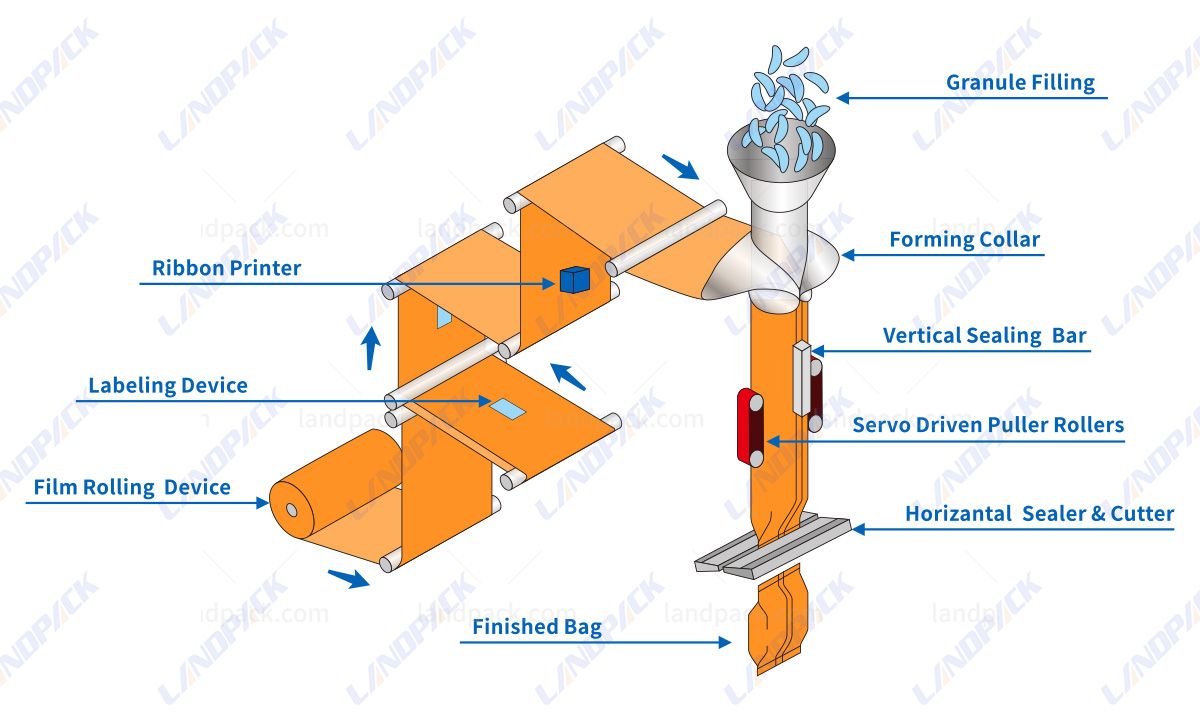

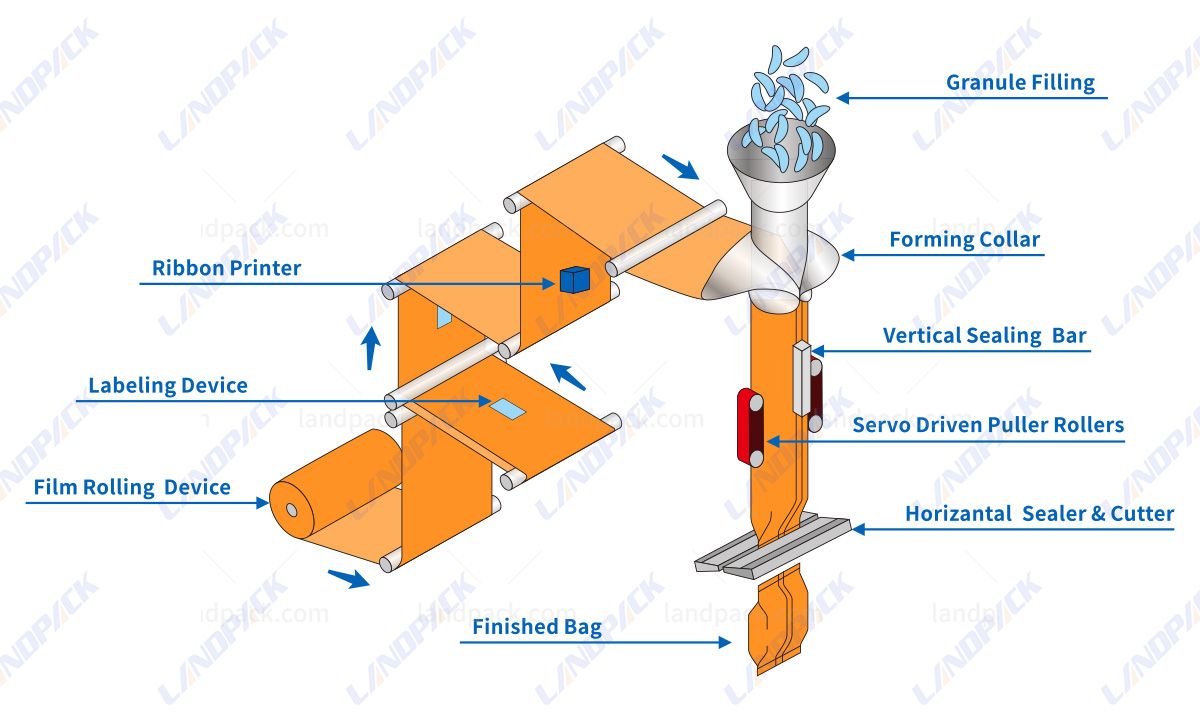

Workflow:

1. Product Feeding: Ice cubes or other granular materials are lifted from the ground hopper to the top of the machine by a Z-type elevator, ensuring smooth and continuous product feeding without damage or melting.

2. Accurate Weighing: A high-precision multi-head weigher automatically measures the target weight for each pack, providing both speed and accuracy while minimizing product loss.

3. Bag Forming: The film roll is pulled down by a servo-driven system and shaped into a bag through the forming tube. The system supports various bag types and sizes for different packaging needs.

4. Product Filling: The weighed ice cubes or granular products are dropped precisely into the formed bag, with anti-stick and anti-splash design to maintain cleanliness and product integrity.

5. Sealing and Cutting: The machine performs reliable heat sealing and cutting simultaneously, creating air-tight, neat seals that protect the product from leakage, moisture, and contamination.

6. Finished Product Output: Packed bags are discharged onto the output conveyor, ready for weighing check, boxing, or palletizing, ensuring a smooth and efficient end-to-end workflow.