Application:

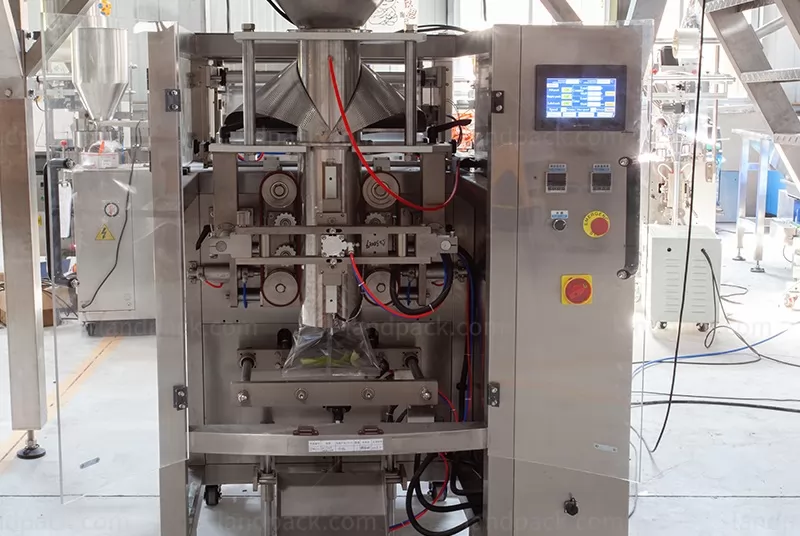

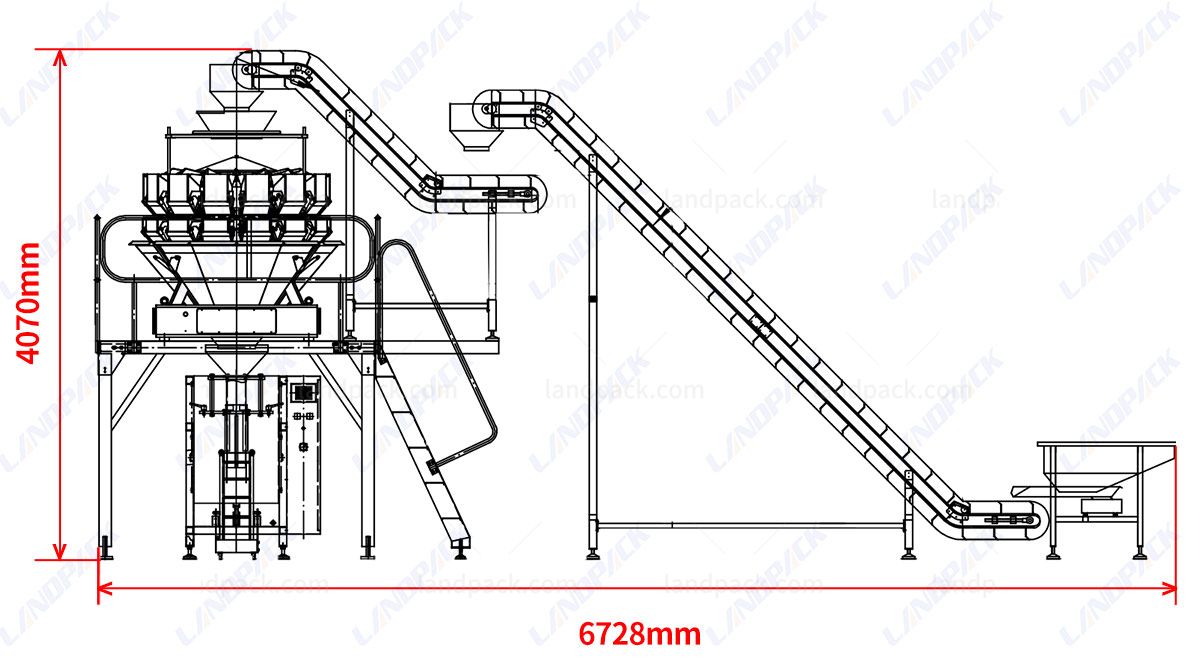

The multihead weigher vertical packing machine is specially designed for ice cube packaging, combining high-speed weighing and reliable sealing in one system. It supports various granular and frozen materials, providing clean, accurate, and durable packaging results for both industrial and retail applications.

Package Type:

This vertical form fill seal packaging machine with a multihead weigher supports a wide range of bag types to meet different packaging needs. It is compatible with: Pillow Bags, Gusset Bags, Quad Seal Bags, Flat Bottom Bags, Chain Bags / Linked Bags.With flexible bag style options, it delivers efficient, clean, and attractive packaging for various granular, frozen, or snack products.

Wide Application Range:

The Vertical Weighing Packaging Machine is a high-performance system designed for precise and efficient packaging of granular, block, or frozen products such as ice cubes.

This machine is widely used across the frozen food, snack, and cold-chain packaging industries, perfectly suited for:

1. Ice Products: cube Ice, crushed Ice, tube Ice.

2. Frozen Fruits & Vegetables: Diced Mango, pineapple, mixed Berries, green peas.

3. Seafood Products: Shrimp, scallops, small Fish, squid Rings.

4. Frozen Prepared Foods: Dumplings, meatballs, mini spring rolls, frozen snacks.

5. Dry & Granular Products: Nuts, seeds, candy, chips, pet food.

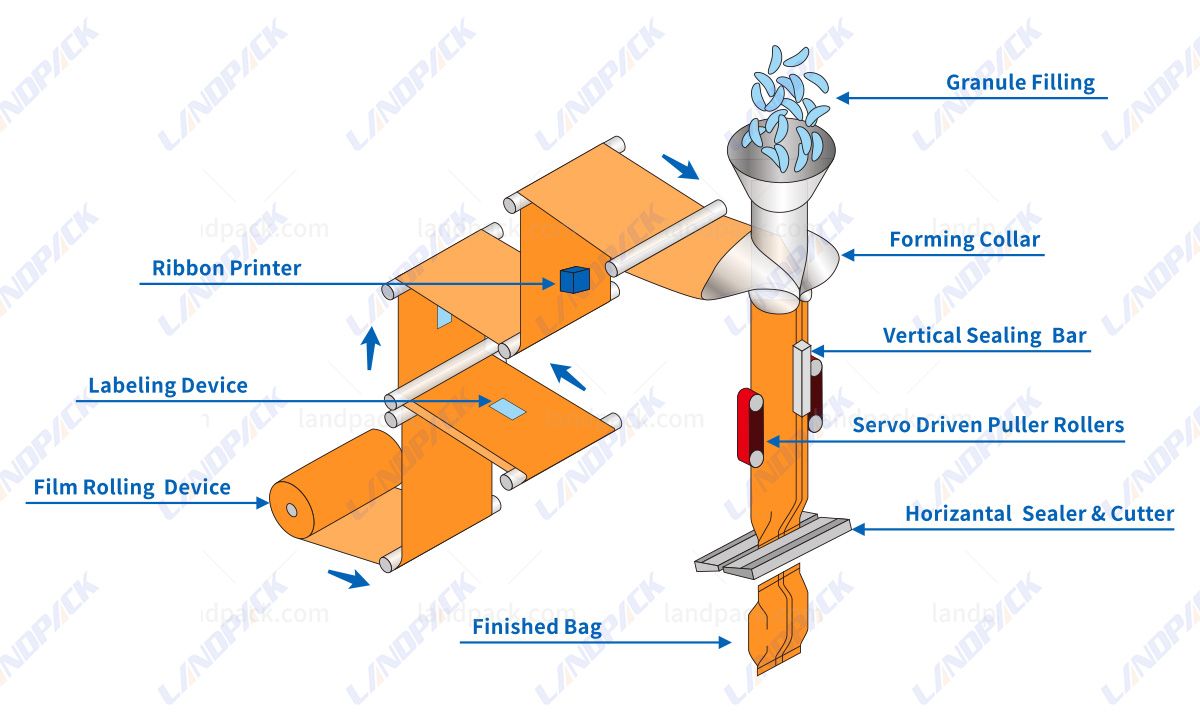

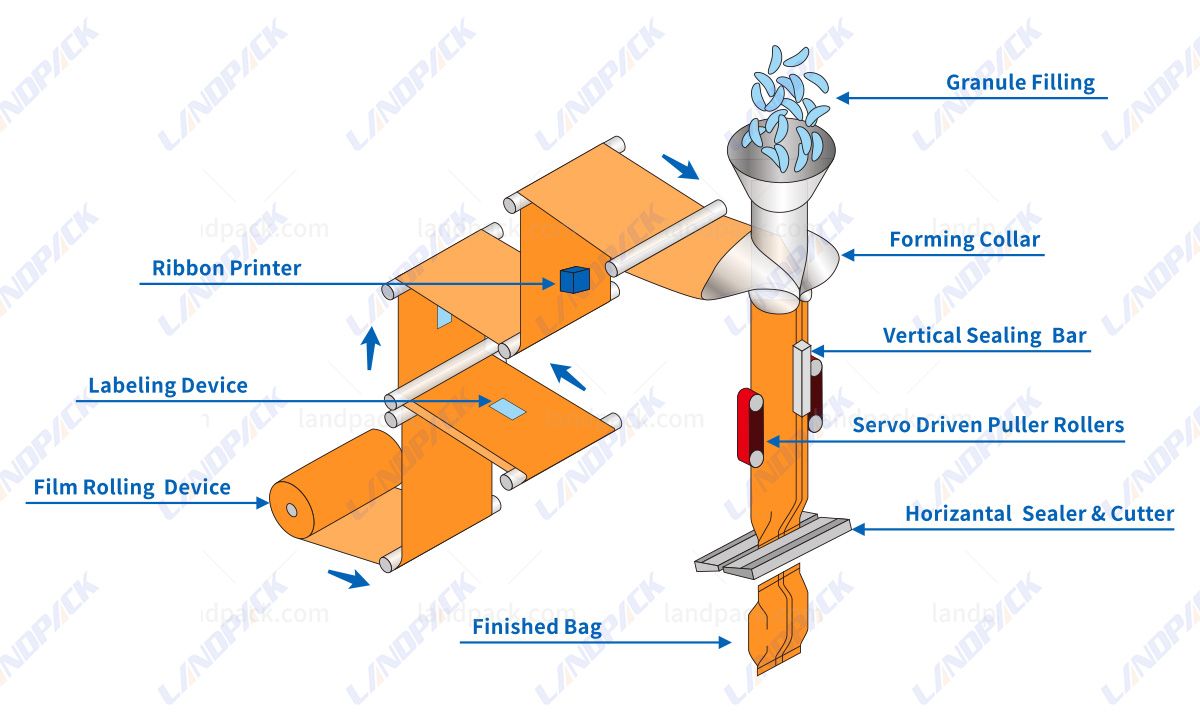

Workflow:

1. Product Feeding: Products are evenly delivered to the multihead weigher through a feeding system for continuous and stable operation.

2. Accurate Weighing: The multihead weigher automatically measures each portion with high precision to ensure consistent bag weight.

3. Bag Forming: Film is pulled and shaped into bags through the forming tube, ready for filling.

4. Product Filling: The weighed products are dropped into the formed bags accurately and smoothly.

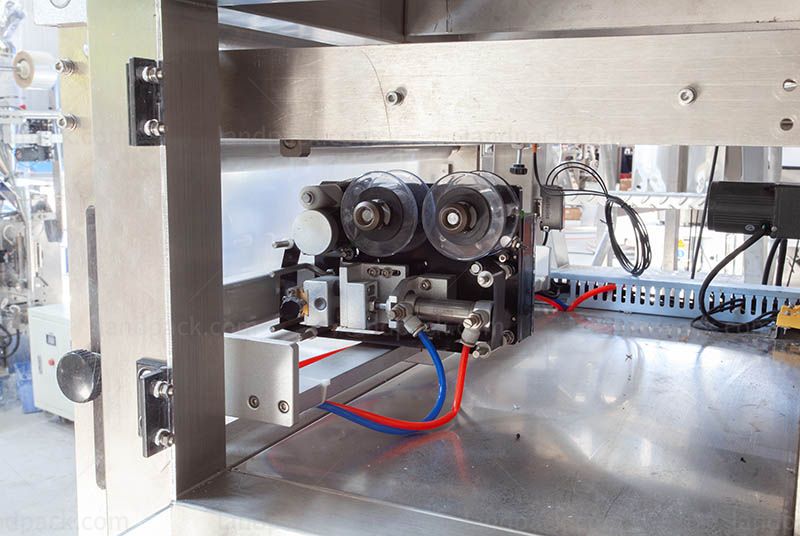

5. Sealing and Cutting: Bags are heat-sealed and cut precisely to ensure strong sealing and a neat appearance.

6. Finished Product Output: Completed packages are automatically discharged, ready for further inspection or cartoning.