Application:

This machine is mainly used for filling and sealing plastic cups with ice cubes, crushed ice, and other chilled or semi-liquid products. It’s widely applied in beverage factories, cold drink shops, and frozen food production lines.

Package Type:

Designed for plastic cup packaging with heat-sealed film or aluminum foil lids, ensuring clean, airtight, and leak-proof sealing. The machine can handle various cup shapes and sizes, including round, square, or custom-designed cups. Ideal for single-serve ice cups, beverage cups, and frozen dessert containers that require neat presentation and extended freshness.

Wide Application Range:

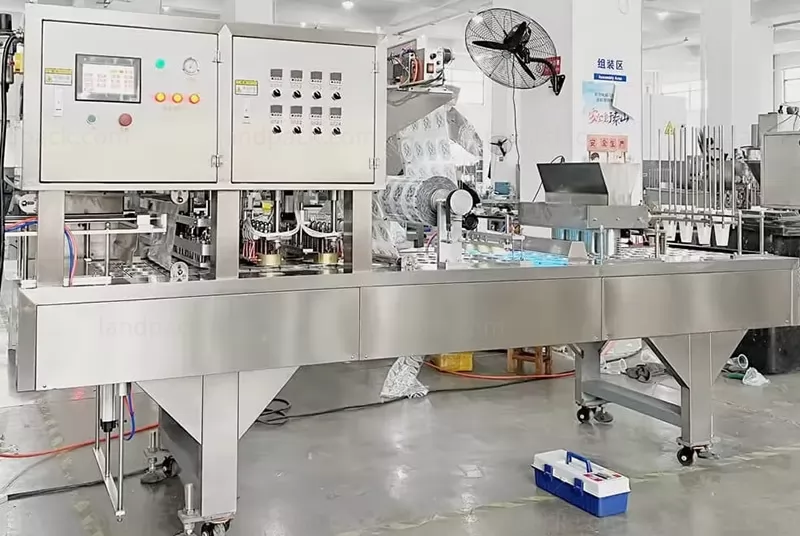

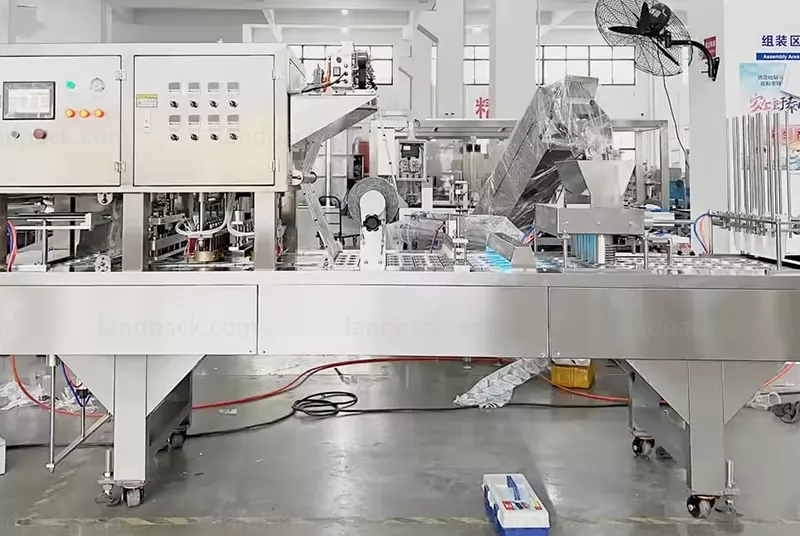

The Fully Automatic Ice Cube Cup Filling Sealing Machine is designed for precise, hygienic, and efficient filling and sealing of ice cubes into plastic cups. With its compact structure, servo-controlled operation, and stable sealing performance, this machine ensures accurate dosing, leak-proof packaging, and attractive presentation — perfect for chilled and frozen product lines.

1. Ice & Beverage Industry

Ideal for packaging regular ice cubes, crushed ice, flavored ice, and beverage ice cups for retail stores, restaurants, and convenience outlets.

2. Dairy & Dessert Industry

Suitable for yogurt, pudding, jelly, smoothies, and frozen desserts that require airtight sealing and freshness preservation.

3. Ready-to-Drink Products

Can be used for fruit juice, energy drinks, or functional beverages packed in portion cups for easy storage and on-the-go consumption

Workflow:

1. Cup Feeding: Empty plastic cups are automatically sorted and fed into the production line in an orderly manner, ensuring stable and continuous operation.

2. Ice Filling: Measured portions of ice cubes or crushed ice are accurately dispensed into each cup using a precision dosing system to maintain uniform weight.

3. Film Placing and Heat Sealing: A film or aluminum foil lid is automatically placed and heat-sealed onto each cup, ensuring airtight, leak-proof, and hygienic packaging.

4. Finished Product Output: Sealed cups are automatically conveyed to the output station or collection platform, ready for secondary packaging or distribution.