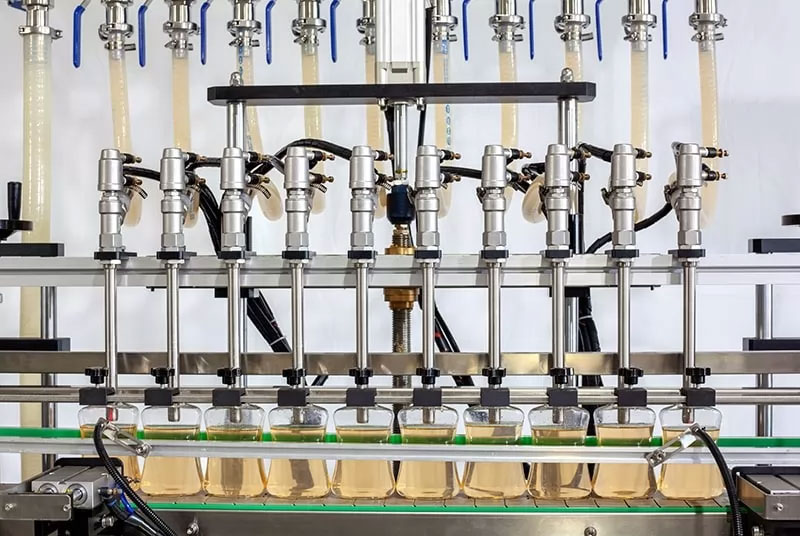

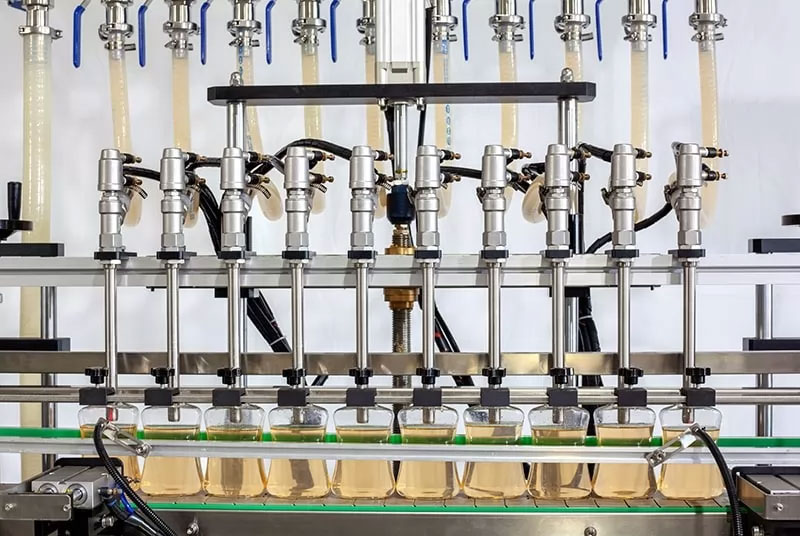

As the name suggests, a liquid quantitative filling machine is a machine that continuously and quantitatively fills liquid into containers through mechanical and programmatic automatic control. In our lives, liquid quantitative filling machines are widely used. For example, manufacturers of soft drinks, alcoholic beverages, and even pharmaceuticals are using them for liquid packaging.

However, there are currently many types of automatic filling equipment on the market, such as plunger filling machines, probe filling machines, weighing filling machines, mechanical valve filling machines, flow meter filling machines, etc. Due to the wide variety, many manufacturers are not familiar with it and inadvertently choose a liquid automatic filling machine that does not meet the actual production needs, resulting in insufficient or overcapacity, which in turn affects the company's production costs.

How did this happen? The key to the problem lies in the methods and steps of purchasing a liquid quantitative filling machine. Just think about it, how do you decide which automatic filling equipment to order? Are you making your choices too subjectively because of a sudden surge in orders?

Specifically, you need to determine the answers to the following four questions before purchasing automatic filling equipment:

1. What is the nature of the product you need to fill?

Liquid properties place different demands on filling machines. For liquid filling with relatively high viscosity, such as dish soap, shower gel, beauty cream, lotion, etc., you can choose a traditional plunger filling machine or a flow meter filling machine with a higher degree of automation. For products with lower viscosity, strong fluidity, and no gas, including drinking water, hot drinks, functional drinks, etc., you can choose a lower-cost mechanical valve filling machine or a highly automated flow meter filling machine. Fruit filling generally uses plunger filling. Due to the larger diameter of the plunger valve, it can accommodate larger fruits and the volume quantification is more accurate. Probe filling or weighing filling is often used for juice filling after fruit filling. Those condiments, such as vinegar, soy sauce, cooking wine, etc., are mostly filled with micro-negative pressure mechanical valves. In recent years, flow meter filling or weighing filling is often used because the latter is more automated and more hygienic. For edible oil filling, due to its non-conductive characteristics, weighing filling or mass flow meter filling is required. For carbonated drinks such as Coke and Sprite, you can use a mechanical valve aerator or a flow meter aerator.

2. What kind of filling container do you need?

This problem can be refined to the size, material, shape, hardness, etc. of the filling container. These factors are closely related to the configuration of filling equipment and will also directly affect product costs. Currently, PET bottles are the most widely used due to their lightweight, flexible appearance, perfect manufacturing process, and extremely low container cost. Glass bottles are heavy and costly to ship. However, due to its stable material performance and long-term resistance to acid, alkali, corrosion, etc., it is often used as a filling container for condiments (vinegar, soy sauce, cooking wine, etc.), yogurt, etc. Highly concentrated foods. Hold the bottle. Glass bottle containers are also used for drinking water, beverages, wine, etc. HDPE bottles are relatively traditional filling containers. The weight is usually between PET bottles and glass bottles, but the material cost is usually higher than the first two. However, its chemical properties are stable and its transportation is safe. It is still commonly used as a daily chemical or chemical product. Filling containers.

3. What level of machine automation do you need?

The degree of automation of the filling machine determines the production efficiency to a certain extent. For manufacturers with low product demand and in the early stages of development, it is also more suitable to choose a linear filling machine with a lower degree of automation. But for companies that want to improve production efficiency, increase output, and reduce labor costs, it is more sensible to choose a fully automatic filling machine.

4. How much space can be reserved for filling equipment in your production workshop?

If your space is limited, you should choose a more compact liquid packaging all-in-one machine, such as a blowing, filling, and capping machine, or a more advanced blowing, labeling, filling, and capping machine. Landpack Packaging Machinery is the domestic creator of these packaging technologies. With several patented technologies, we can provide customers with customized filling solutions based on local conditions.

Summarize

As a leading machinery and equipment manufacturer in China's liquid filling industry, Landpack is committed to providing nearly perfect automated packaging solutions for the new generation of smart production workshops and factories. While ensuring extremely high production efficiency, our quantitative filling machines can also ensure hygiene, accuracy, and energy saving throughout the entire process. If you want to know more about our filling machines, please come for a consultation and we will answer your questions as soon as possible!

Thank you for reading, please get in touch with us if you have any inquiries.

LANDPACK would be your reliable supplier of packing machines.

If you have any questions about the machine, feel free to contact us or leave your machine inquiry on our website, our sales managers and engineers will be here to support you and provide you with a suitable packing solution.

You could contact us by our website address or phone number, our sales managers will contact you in time and give you professional suggestions. And our engineers are willing to help you to solve the machine problem and teach you one step by step on video calling.