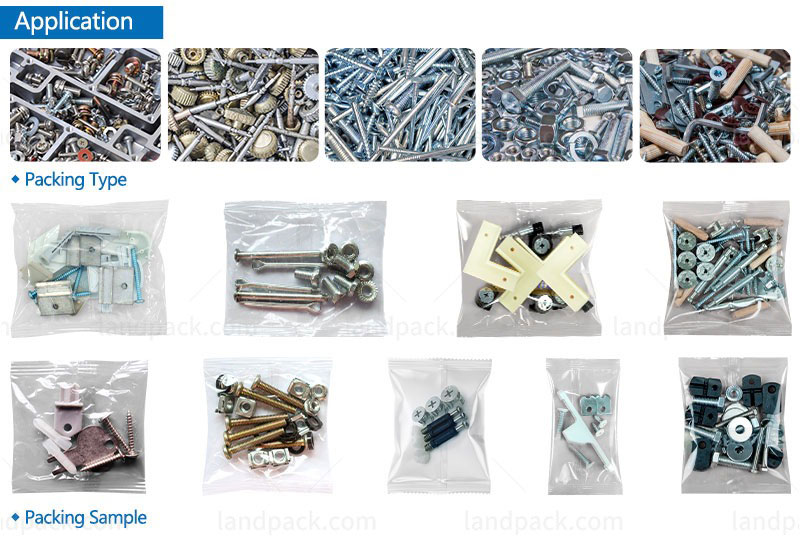

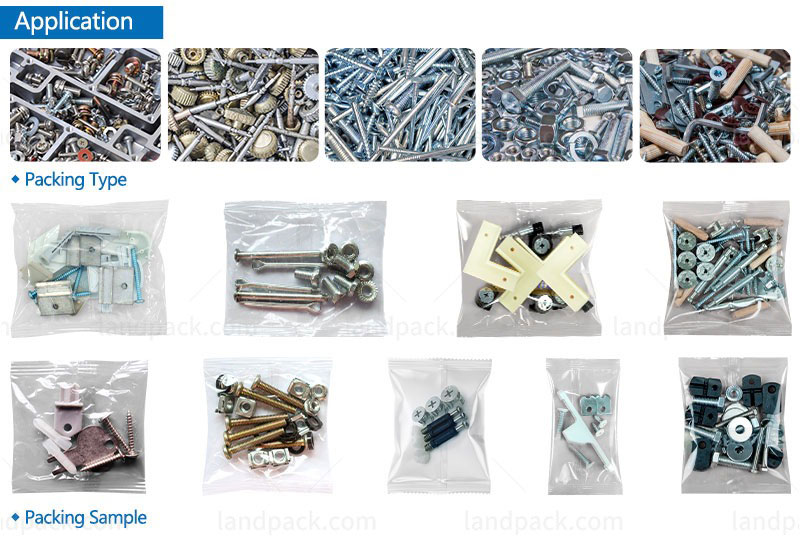

The packaging of hardware screw products is relatively common in daily life, such as furniture accessories packages, machinery accessories packages, hardware small bags, etc. These small packages contain many or more different types of small hardware pieces. The packaging of this kind of product with different specifications and many types is completed by a professional equipment hardware screw packaging machine. This equipment has a variety of options to meet different packaging needs.

A fully automatic hardware screw packaging machine generally consists of the following four parts: feeding device, measuring equipment, packaging host, and finished product conveyor.

Loading equipment: Generally, it is a Z-type material elevator or a climbing elevator. The Z-type material elevator is carried out in a closed state during the loading process, which can prevent hardware screw products from falling out during the loading process. When you need to package products with larger volumes, you can use a climbing loader to load materials. It transports materials in an open state and has very few volume restrictions.

Measuring equipment: The measurement of hardware screw products can be measured in the form of counting according to the volume and specific gravity of the material. The equipment used is a counting plate. Another method of measurement is in the form of weighing. The equipment used is an electronic combination scale. The combination scale has fast measurement speed, high accuracy, and more efficiency advantages.

Packaging host: LD420/520/620/720 and other models can be selected. This needs to be determined according to the actual packaging bag size. The number in the model represents the maximum film width. Taking LD420 as an example, 420 represents the maximum film width of 420mm. The calculation formula is bag width = (420mm-20mm)/2 = 200mm. So when the maximum width of your packaging bag is less than 200mm, you can choose the LD420 series. At the same time, they are also compatible with roll film packaging production of different materials, such as composite film, PE film, and other roll films.

Finished product conveying equipment: generally refers to the finished product conveying equipment designed by the manufacturer according to the size of the customer's packaging bag. When the machine packaging is completed, the finished product conveying equipment outputs the finished product to the workbench's height, which can maximize packaging efficiency and achieve more efficient automated packaging.

Generally used hardware screw packaging machine solutions can be made into automatic packaging in counting form, or in weighing form. Which solution is more suitable depends on the actual characteristics of the product and the packaging effect requirements. In addition to the standard solution, there are also customized solutions.

Thank you for reading, please get in touch with us if you have any inquiries.

LANDPACK would be your reliable supplier of packing machines.

If you have any questions about the machine, feel free to contact us or leave your machine inquiry on our website, our sales managers and engineers will be here to support you and provide you with a suitable packing solution.

You could contact us by our website address or phone number, our sales managers will contact you in time and give you professional suggestions. And our engineers are willing to help you to solve the machine problem and teach you one step by step on video calling.